Sludge dewatering and granulating device and method with synergic effect of annular electric field and pressure

A synergistic and sludge dewatering technology, which is applied in the direction of raw material extrusion granulation, dehydration/drying/thickened sludge treatment, etc., can solve the problems of large impact of water penetration and removal, uneven pressure distribution, and difficulty in realizing particle shape, etc. problems, achieve the effects of reducing water movement resistance, uniform pressure distribution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

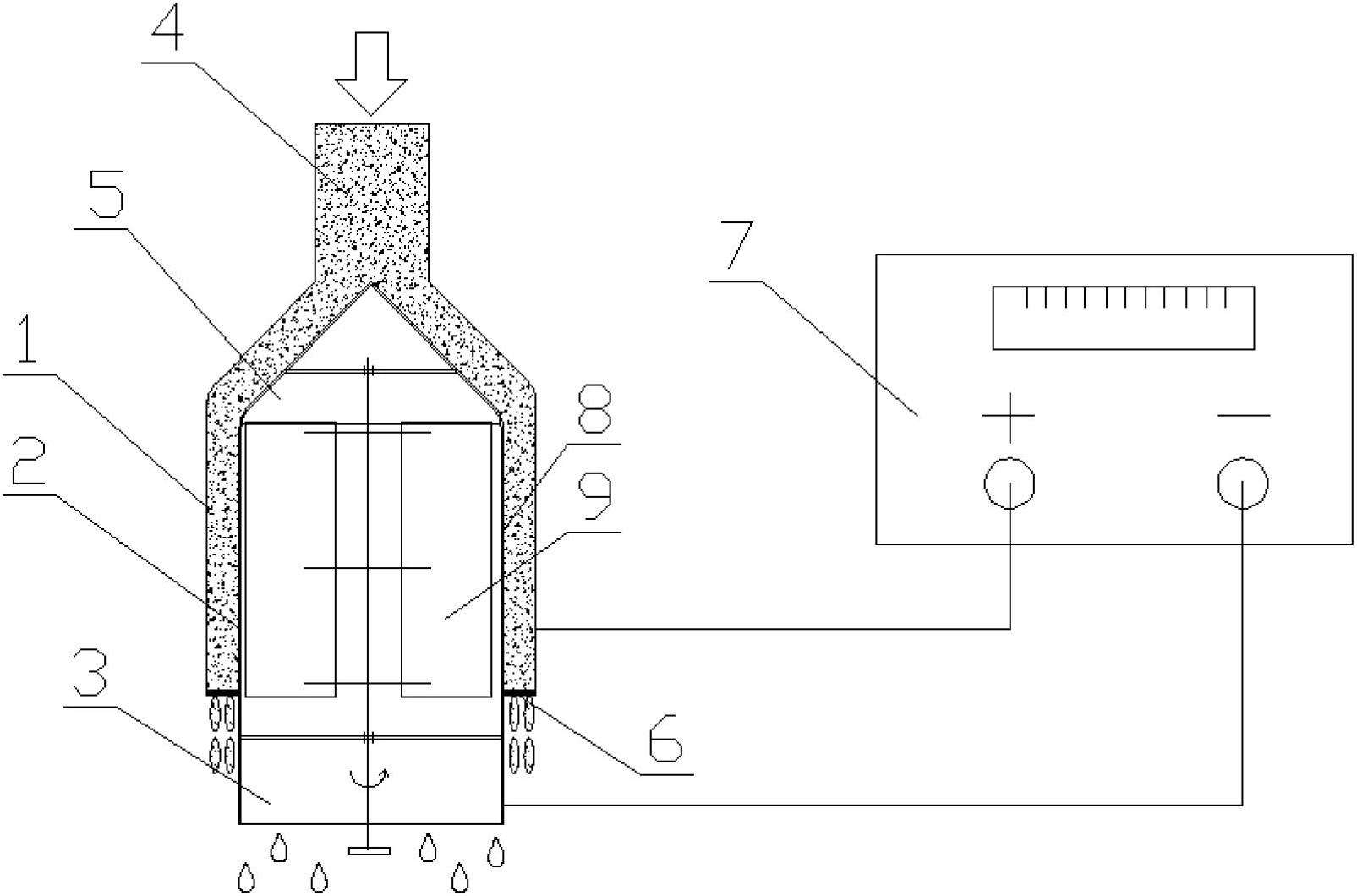

[0030] Such as figure 1 As shown, the metal cylinder anode 1 and the mesh cylinder cathode 3 are concentrically arranged in a sleeve with a distance of 5mm, and are connected to the positive and negative poles of the DC power supply 7 respectively. A filter cloth 8 is laid between the mesh cathode 3 and the sludge 2 . The dewatered sludge 2 with a moisture content of 85% is injected from the mud inlet 4 after being pressurized at 100,000 Pa, diverted by the conical baffle plate 5 with a conical apex angle of 60°, and then enters the annular electric field. The outlet moves, and the water in the sludge passes through the filter cloth 8 and the cathode 3 and is scraped off by the scraper 9 to complete the dehydration process. The dehydrated sludge is extruded into granules by the granulation baffle 6 and then discharged. The shape of the sludge discharge port is circular, and the opening rate is 50%. The DC power supply adopts a continuous voltage regulation method, and the po...

Embodiment 2

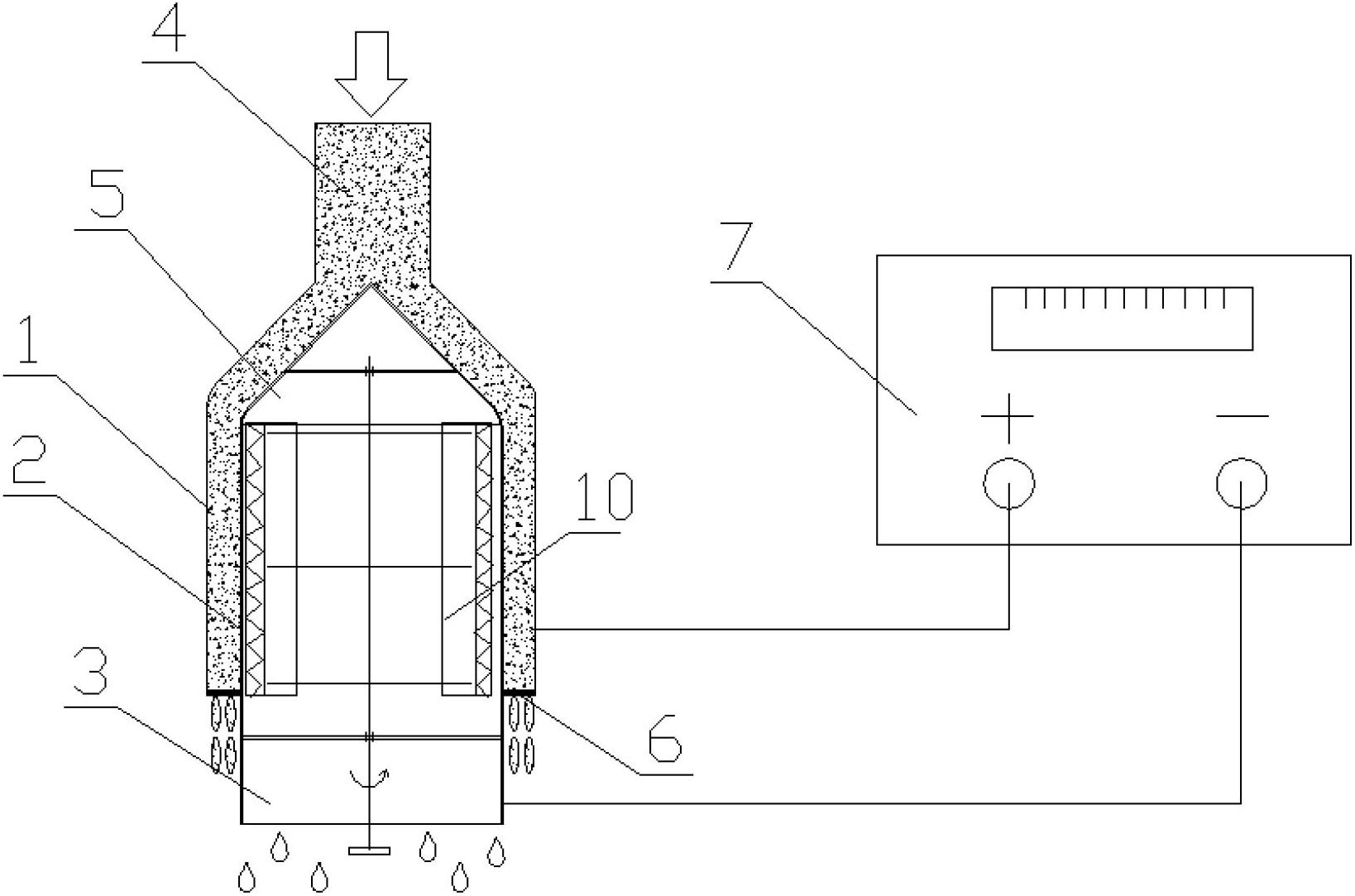

[0032] Such as figure 2 As shown, the metal cylinder anode 1 and the mesh cylinder cathode 3 are concentrically arranged as a sleeve with a distance of 2 mm, and are respectively connected to the positive and negative poles of the DC power supply 7 . Mesh cathode 3 itself has filtering function. The dewatered sludge 2 with a water content of 90% is injected from the mud inlet 4 after being pressurized at 1000 Pa, diverted by the conical baffle plate 5 with a conical apex angle of 60°, and then enters the annular electric field. The outlet moves, and the moisture in the sludge passes through the cathode 3 and is brushed away by the brush 10 to complete the dehydration process. The dehydrated sludge is extruded into granules by the granulation baffle 6 and then discharged. The shape of the sludge discharge port is oval, and the opening ratio is 80%. The DC power supply adopts a continuous voltage regulation method, and the power supply voltage is 10V. After the sludge is deh...

Embodiment 3

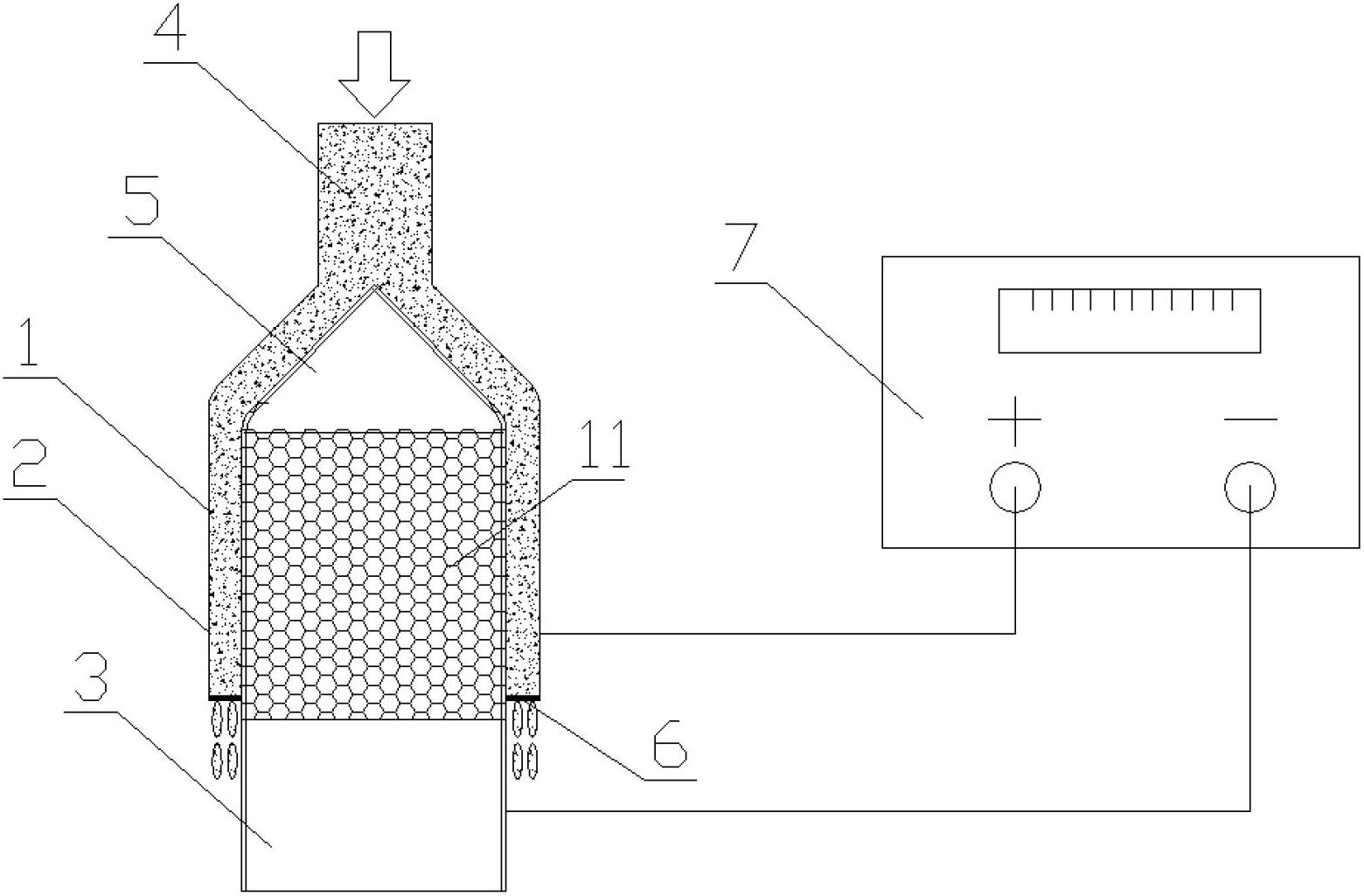

[0034] Such as image 3 As shown, the metal cylinder anode 1 and the mesh cylinder cathode 3 are concentrically arranged in a sleeve with a distance of 20 mm, and are respectively connected to the positive and negative poles of the DC power supply 7 . Mesh cathode 3 itself has filtering function. The dewatered sludge 2 with a moisture content of 50% is injected from the mud inlet 4 after being pressurized at 300,000 Pa, diverted by the conical baffle plate 5 with a conical apex angle of 120°, and then enters the annular electric field. The outlet moves, and the moisture in the sludge passes through the cathode 3 and is separated by the water-absorbing material 11 to complete the dehydration process. The dehydrated sludge is extruded into granules by the granulation baffle 6 and then discharged. The shape of the sludge discharge port is square and the opening ratio is 30%. The DC power supply adopts the pulse power supply mode, the power supply voltage is 150-200V, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com