ZrC-SiC-LaB6 ternary superhigh temperature ceramic composite material and preparation method thereof

A technology for ultra-high temperature ceramics and composite materials, applied in the field of ultra-high temperature ceramic composite materials and their preparation, can solve the problems of high brittleness, poor ablation performance, and low density of ZrC ceramics, achieve structural integrity, improve mechanical properties, and improve effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

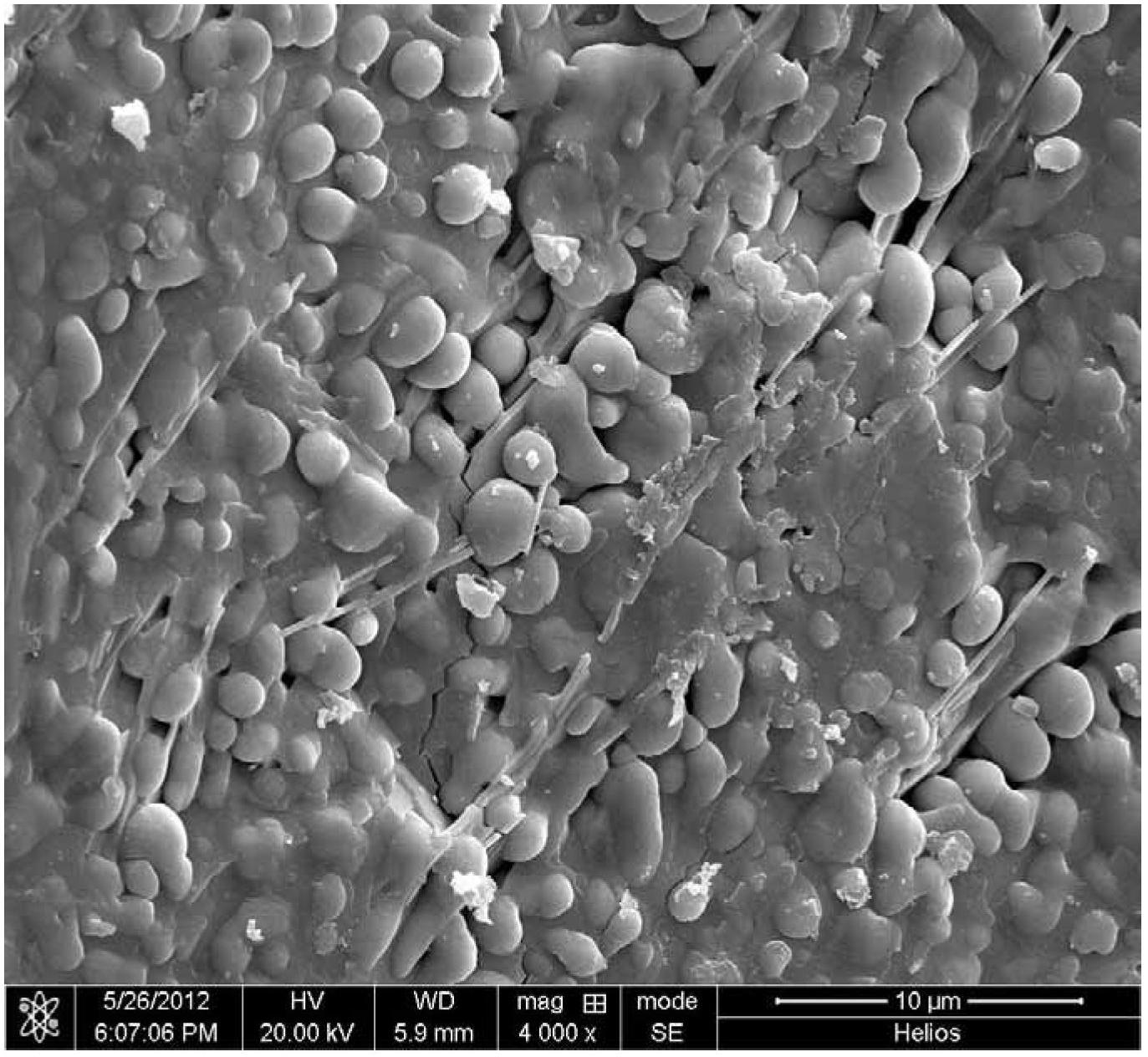

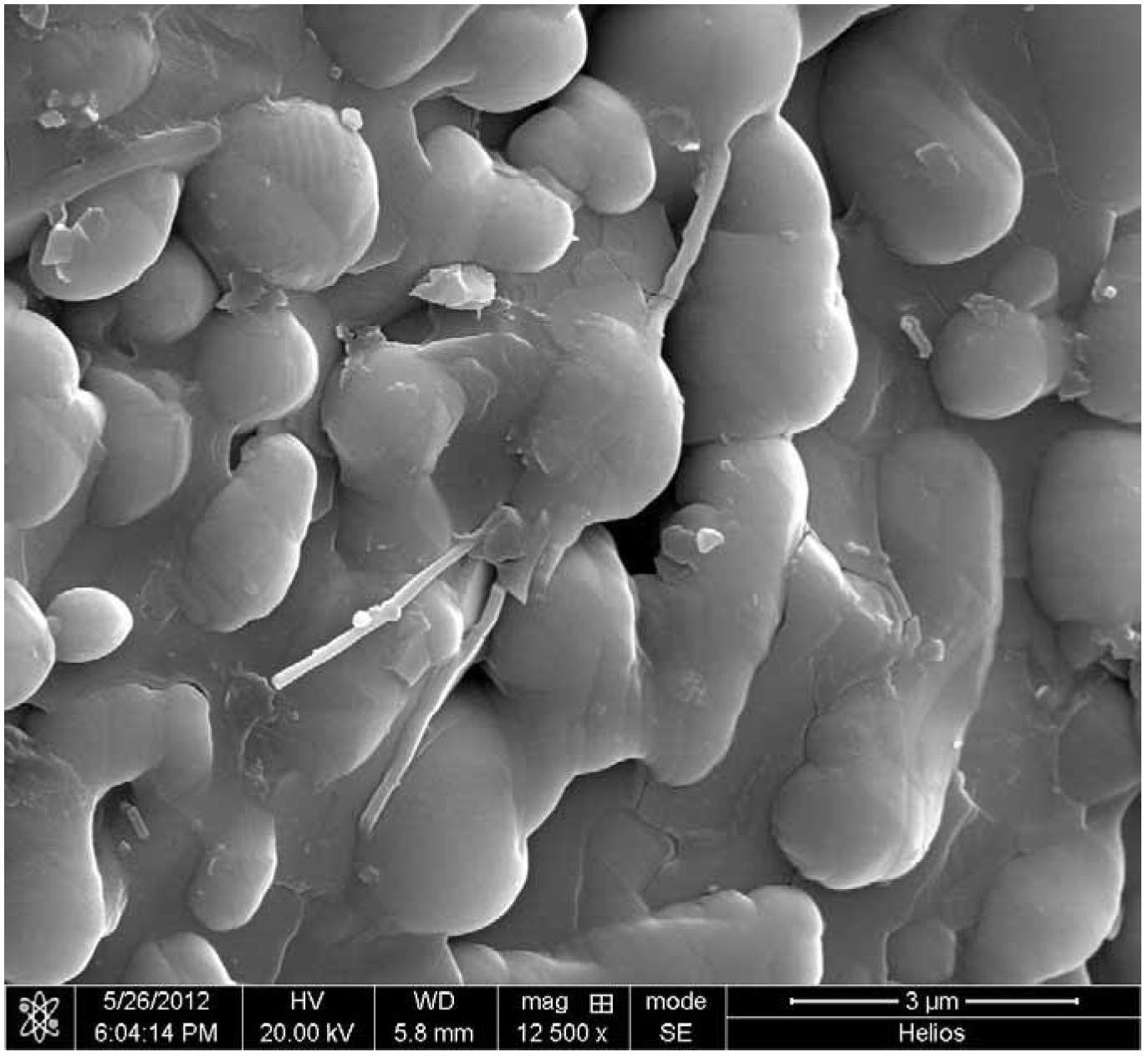

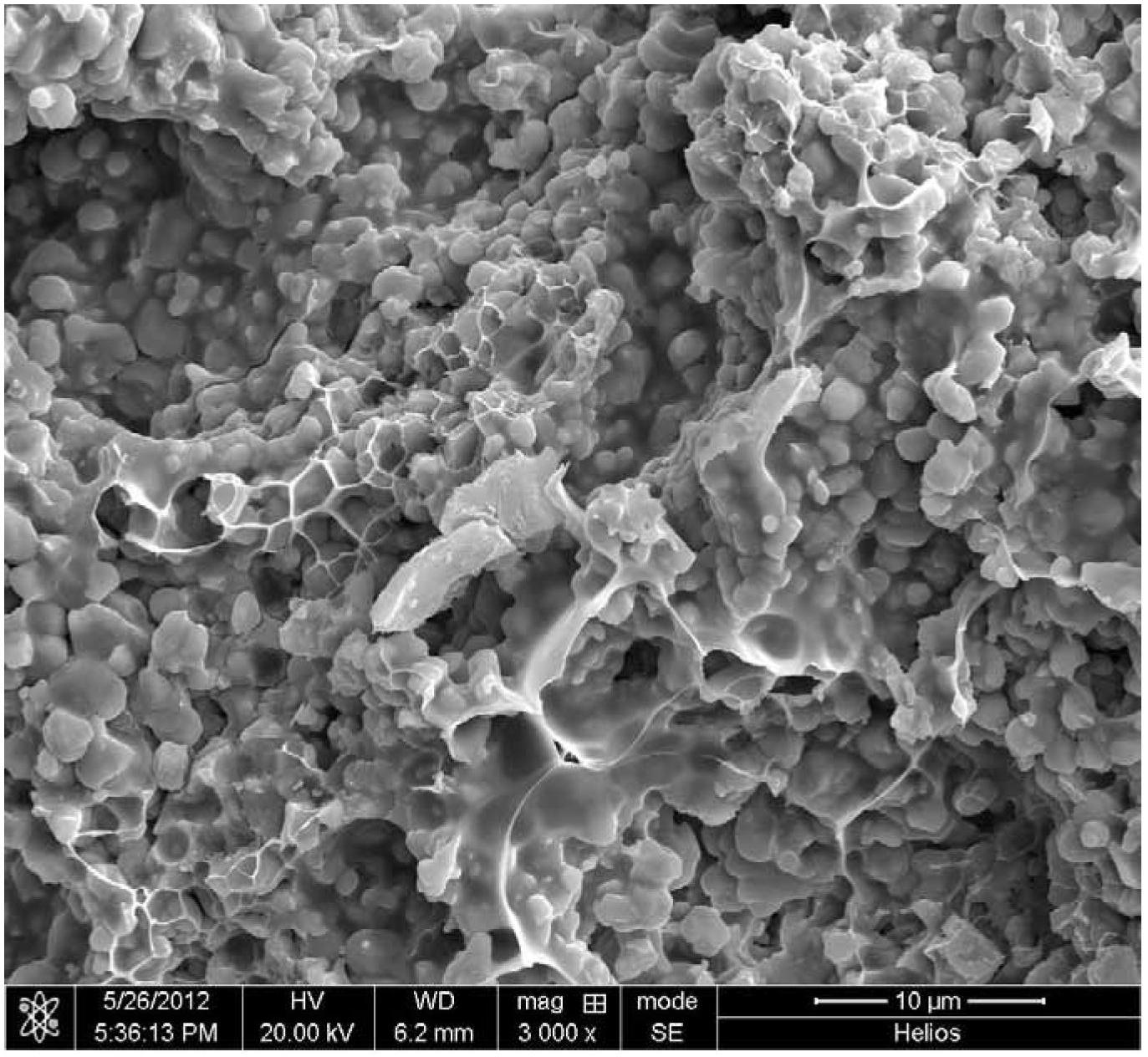

[0020] Specific implementation mode one: this implementation mode ZrC-SiC-LaB 6 The ternary ultra-high temperature ceramic composite material consists of 60% to 85% ZrC powder, 5% to 14% SiC nanoparticles, 5% to 14% SiC whiskers and 5% to 12% LaB according to the volume fraction. 6 Powder composition.

[0021] In this embodiment, ZrC-SiC-LaB 6 A preferred composition of the ternary ultra-high temperature ceramic composite material is: by volume fraction 70% ZrC powder, 10% SiC nanoparticles, 10% SiC whiskers and 10% LaB 6 Made from powder.

[0022] The beneficial effects of this embodiment are: this embodiment adds SiC nanoparticles, SiC whiskers and LaB 6 The powder, SiC nanoparticles and SiC whiskers play the role of SiC nanoparticles and SiC whiskers mixed and toughened ZrC-based ultra-high temperature ceramic composites, thereby improving the mechanical properties of the ceramics. LaB 6 The powder acts as a sintering aid and improves ablation performance, LaB 6 The p...

specific Embodiment approach 2

[0023] Specific implementation mode two: this implementation mode ZrC-SiC-LaB 6 The preparation method of the ternary ultra-high temperature ceramic composite material is carried out according to the following steps:

[0024] 1. Weigh 60%-85% ZrC powder, 5%-14% SiC nanoparticles, 5%-14% SiC whiskers and 5%-12% LaB by volume fraction 6 powder;

[0025] 2. Using absolute ethanol as a dispersant, disperse the SiC whiskers weighed in step 1 by ultrasonic waves to obtain evenly dispersed SiC whiskers;

[0026] 3. Combine the uniformly dispersed SiC whiskers obtained in step 2 with the ZrC powder, SiC nanoparticles and LaB obtained in step 1 6 After the powder is mixed, it is added to a ball mill, with absolute ethanol as a dispersant, ZrO 2 The ball is used as the ball milling medium, and the ball mill is mixed evenly to obtain the slurry;

[0027] 4. Using a rotary evaporator to dry the slurry obtained in step 4 to obtain a mixed powder;

[0028] 5. Put the mixed powder obtai...

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the method for ultrasonic dispersion treatment in step two is carried out according to the following steps: with absolute ethanol as dispersant, the consumption ratio of SiC whisker and absolute ethanol is 1g : (5mL ~ 35mL), under the conditions of working voltage of 220V and frequency of 20 ~ 25kHz, ultrasonic treatment for 3min ~ 10min. Others are the same as in the second embodiment.

[0038] In this embodiment, the ratio of SiC whiskers to absolute ethanol is preferably 1 g: 20 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com