Nano carbon material reinforced epoxy resin composite material and preparation method thereof

A nano-carbon material and epoxy resin technology, applied in the field of composite materials, can solve problems such as unfavorable nano-devices, high magnetic field strength requirements, and loss of orientation of nano-carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

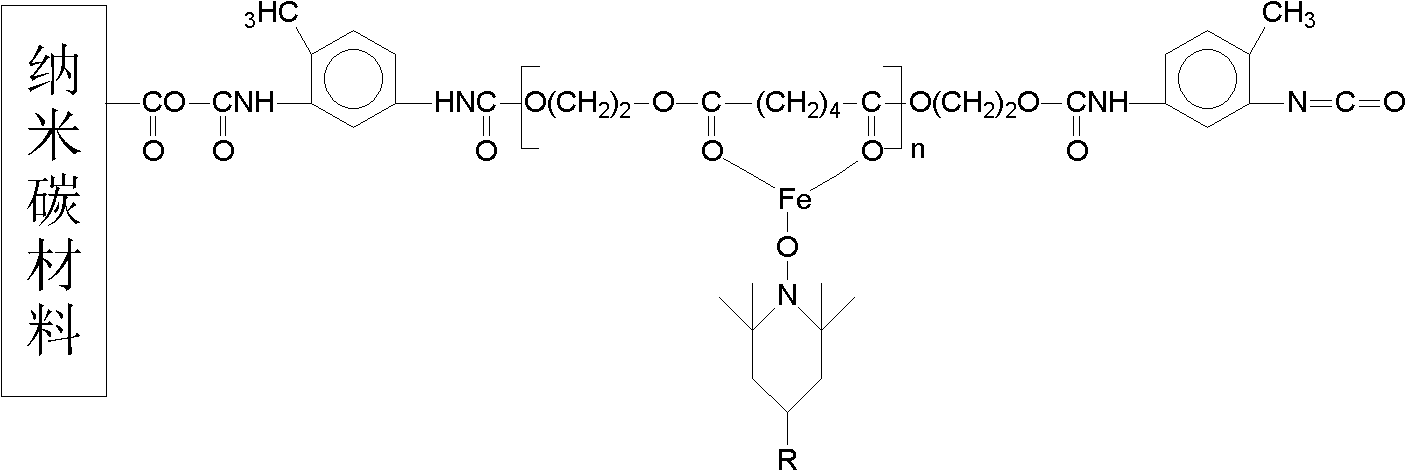

[0032] A nano-carbon material-reinforced epoxy resin composite material in this embodiment is composed of the following components in weight percentage: cured epoxy resin and 0.1 wt% of it modified graphene oxide by paramagnetic oligomer. Concrete preparation method is as follows steps:

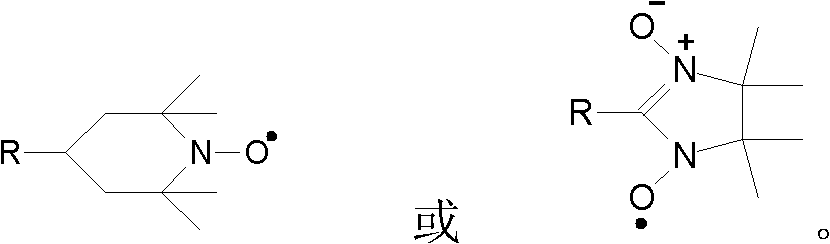

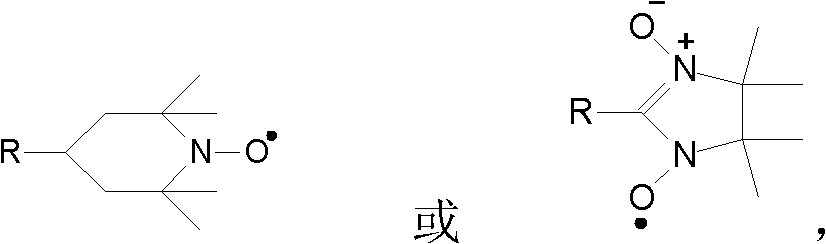

[0033] 1) 10g of 4-hydroxyl-2,2,6,6-tetramethyl-piperidine-1-oxyl free radicals are dissolved in 90g of methanol, and then slowly added dropwise to 9.5g of ferric chloride by weight Percentage is 10% in the methanol solution, after reacting for 20 hours, the solvent is evaporated to dryness to obtain a complex compound of ferric ion;

[0034] 2) The ferric ion complex compound of 10g is dissolved in 23.3g acetone, then it is slowly added dropwise to 10g molecular weight in the polyester diol that is 1000 (the mol ratio of complex and polyester diol is 3 : 1), stirred and reacted for 20 hours, and the solvent was evaporated to dryness to obtain the trivalent iron complex of polyester diol;

...

Embodiment 2

[0039] A nano-carbon material reinforced epoxy resin composite material in this embodiment is composed of the following components by weight percentage: cured epoxy resin and oxidized carbon nanotubes modified by paramagnetic oligomer accounting for 3% by weight. Concrete preparation method is as follows steps:

[0040] 1) 10g of 4-hydroxyl-2,2,6,6-tetramethyl-piperidine-1-oxyl free radicals are dissolved in 23g of ethanol, and then slowly added dropwise to 9.5g ferric chloride weight Percentage is 30% in the ethanol solution, after reacting for 24 hours, evaporate the solvent to dryness to obtain a complex compound of ferric ion;

[0041] 2) Dissolve 10g of the ferric ion complex compound in 90g of acetone, then slowly add it dropwise to 10g of polyester diol with a molecular weight of 2000 (the molar ratio of complex to polyester diol is 6: 1), stirring and reacting for 24 hours, evaporating the solvent to obtain the trivalent iron complex of polyester diol;

[0042] 3) Add ...

Embodiment 3

[0046] A nano-carbon material reinforced epoxy resin composite material in this embodiment is composed of the following components by weight percentage: cured epoxy resin and graphene oxide modified by paramagnetic oligomer accounting for 5% by weight. Concrete preparation method is as follows steps:

[0047] 1) 1g of 4-hydroxyl-2,2,6,6-tetramethyl-piperidine-1-oxyl free radical is dissolved in 99g of ethanol, and then it is slowly added dropwise to the weight of 0.95g ferric chloride Percentage is 10% in the methanol solution, after reacting for 10 hours, the solvent is evaporated to dryness to obtain a complex compound of ferric ion;

[0048] 2) Dissolve the ferric ion complex compound of 1g in 99g acetone, then slowly add it dropwise to 1g of polyester diol with a molecular weight of 3000 (the molar ratio of complex and polyester diol is 9: 1), stirring and reacting for 10 hours, evaporating the solvent to obtain the trivalent iron complex of polyester diol;

[0049] 3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com