Coagulating bath solution of polyacrylonitrile-based protofilament, preparation method and application

A technology of polyacrylonitrile-based raw silk and coagulation bath, which is applied in rayon manufacturing, wet spinning, textiles and papermaking, etc. It can solve the problem that is not conducive to improving the uniformity of spinning speed and reducing the change of double diffusion speed , speed up the double diffusion process and other issues, to achieve the effect of reducing the double diffusion change rate, increasing the double diffusion speed, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix dimethyl sulfoxide and water at a volume ratio of dimethyl sulfoxide: water of 120:100, and mix evenly at 45°C to prepare an aqueous solution of dimethyl sulfoxide.

[0026] (2) Add ethylene glycol to the dimethyl sulfoxide aqueous solution, mix well at 45°C, make the ethylene glycol content in the dimethyl sulfoxide aqueous solution 0.02mol / L, and obtain the coagulation bath solution.

[0027] (3) The spinning solution enters the coagulation bath solution through the spinneret to form primary fibers, and the residence time of the fibers in the coagulation bath is 4 seconds.

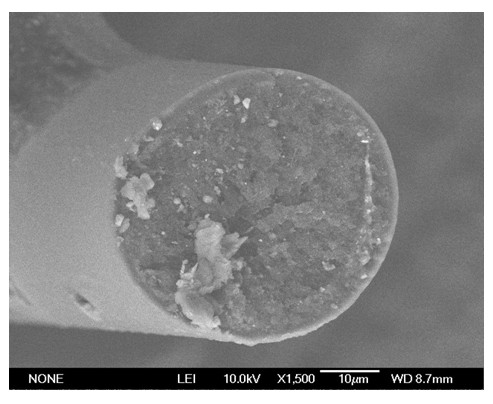

[0028] The prepared nascent fibers were analyzed with a scanning electron microscope, and the electron microscope pictures ( figure 1 ) The cross-sectional morphology of the primary fibers on the surface is relatively round. The fiber body density is measured by the specific gravity method, and the fiber body density is 1.190g / cm 3 .

Embodiment 2

[0030] 1. Mix dimethyl sulfoxide and water at a volume ratio of dimethyl sulfoxide: water of 160:100, and mix evenly at 50°C to prepare an aqueous solution of dimethyl sulfoxide.

[0031] 2. Add acetone to the dimethyl sulfoxide aqueous solution, and mix evenly at 50° C. so that the acetone content in the dimethyl sulfoxide aqueous solution is 0.04 mol / L to obtain a coagulation bath solution.

[0032] 3. The spinning solution enters the coagulation bath through the spinneret to form primary fibers, and the residence time of the fibers in the coagulation bath is 3.2 seconds.

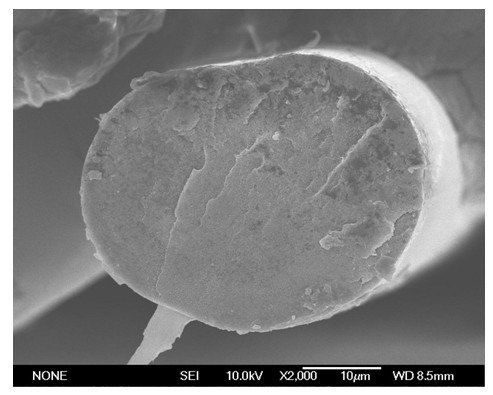

[0033] The prepared nascent fibers were analyzed with a scanning electron microscope, and the electron microscope pictures ( figure 2 ) The cross-sectional morphology of the primary fibers on the surface is relatively round. The fiber body density is measured by the specific gravity method, and the fiber body density is 1.192g / cm 3 .

Embodiment 3

[0035] (1) Mix dimethyl sulfoxide and water at a volume ratio of dimethyl sulfoxide: water of 200:100, and mix evenly at 60°C to prepare an aqueous solution of dimethyl sulfoxide.

[0036] (2) Add ammonium carbonate to the dimethyl sulfoxide aqueous solution, mix well at 55°C, make the ammonium carbonate content in the dimethyl sulfoxide aqueous solution 0.04mol / L, and obtain a coagulation bath solution.

[0037] (3) The spinning solution enters the coagulation bath through the spinneret to form primary fibers, and the residence time of the fibers in the coagulation bath is 5 seconds.

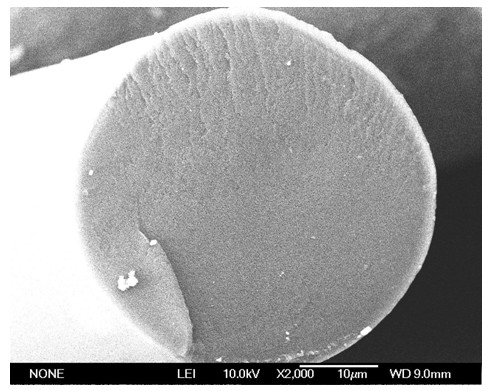

[0038] The prepared nascent fibers were analyzed with a scanning electron microscope, and the electron microscope pictures ( image 3 ) The cross-sectional morphology of the primary fibers on the surface is relatively round. The fiber body density is measured by the specific gravity method, and the fiber body density is 1.192g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com