Nano-structure layer for gallium-nitride-based (GaN-based) light emitting diode (LED) epitaxial slice and preparation method thereof

An LED epitaxial wafer and nanostructure technology, which is applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large non-radiative loss, easy oxidation of metal Ag, reduce surface plasmon coupling output, etc., to improve luminous efficiency. , the effect of preventing oxidation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below to figure 1 The blue-light GaN-based LED epitaxial wafer with an emission wavelength of 480 nm is taken as an example to illustrate the present invention in detail.

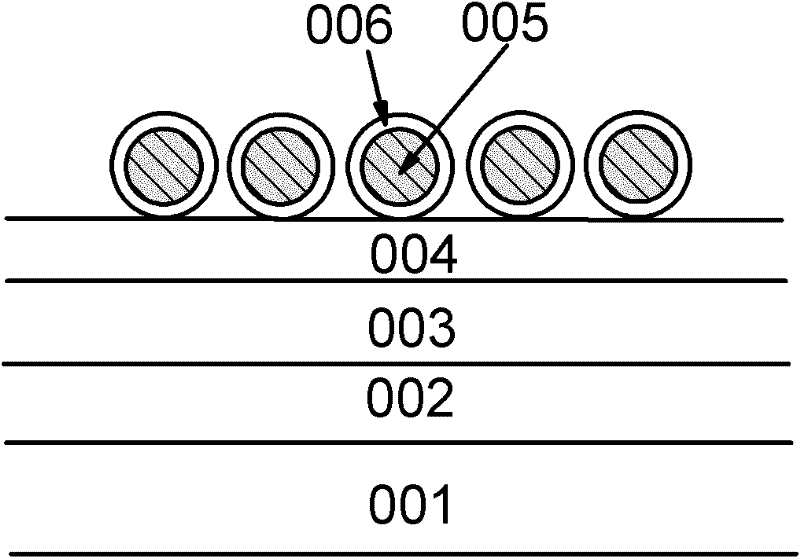

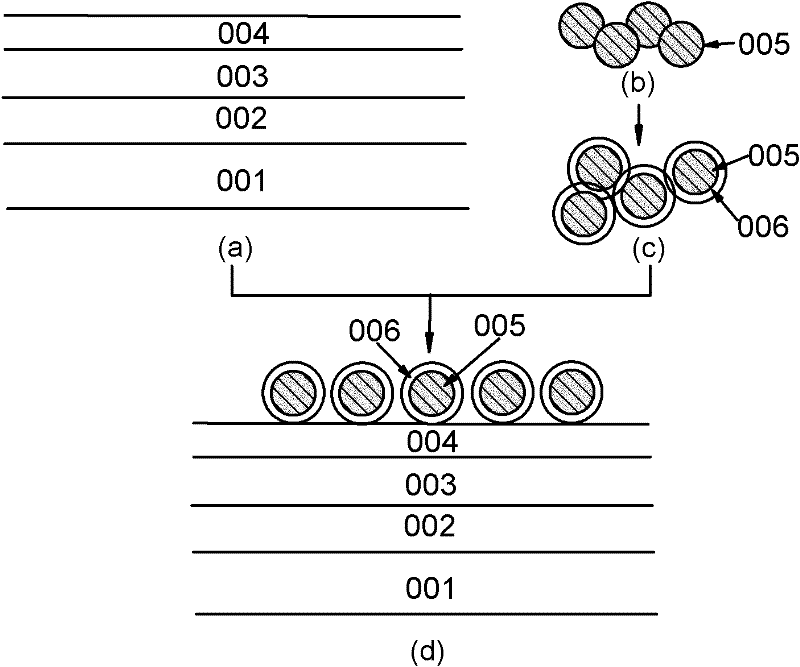

[0029] Such as figure 1 As shown, the LED epitaxial wafer includes a substrate 001, which can be a common LED substrate material such as sapphire. Located on the substrate 001 is a buffer layer 002, such as a GaN layer with certain doping. InGaN / GaN quantum well structure 003 (InGaN is the well layer, GaN is the barrier layer) is located on the buffer layer 002, and the light emission wavelength is around 480nm, which is the active part of the epitaxial wafer. On the InGaN / GaN quantum well layer is a GaN isolation layer 004 with a thickness of about 50nm to reduce the annihilation of the light field. The LED epitaxial wafer may also include a layer (or film) containing a plurality of Ag nanoparticles 005 (with a single crystal structure), wherein the surface of each Ag nanoparticle 005 is coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com