Method for preparing hyaluronate oligomer according to digestion method, prepared hyaluronate oligomer and application thereof

A hyaluronic acid salt and hyaluronic acid technology, applied in the biological field, can solve the problems of low degrading enzyme activity, limited sources, and high cost, and achieve broad application prospects, high enzyme thermal stability and pH stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

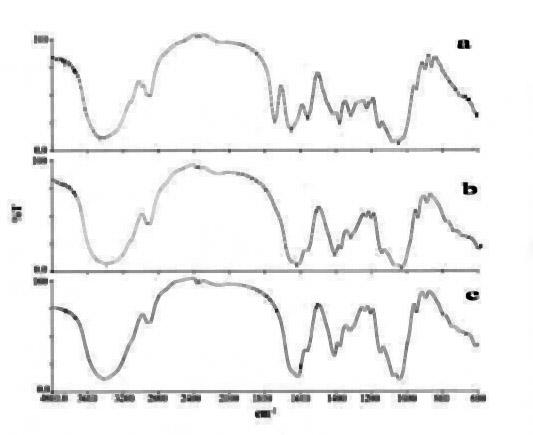

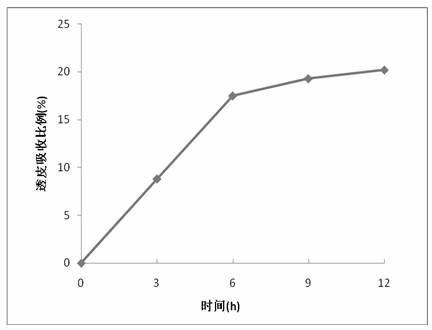

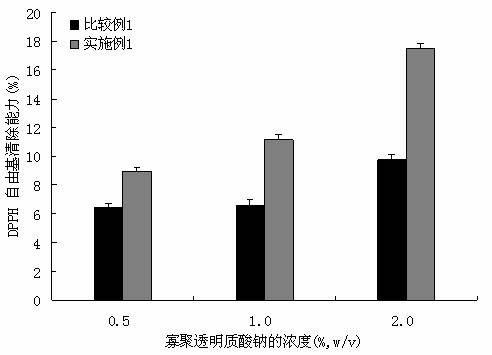

Image

Examples

Embodiment 1

[0065] Inclined medium composition (100mL): Peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O 0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, agar powder 2g, adjust the pH to 6.0 with hydrochloric acid.

[0066] Composition of seed culture medium (100mL): Peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O 0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, adjust the pH to 6.0 with hydrochloric acid.

[0067] Composition of fermentation medium (100mL): Peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O 0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, Tween80 (Tween 80) 0.05mL.

[0068] Take the slant strain (Bacillus sp. A50 CGMCC NO. 5744) and inoculate it in the sterilized seed culture medium, incubate at 25°C and 150 rpm for 24 hours, and then inoculate the seed liquid into the sterilized fermentation medium The inoculum was 10%, cultured at 25°C, 200 rpm for 24 hours. During the fermentation, the pH was maintained at 6.0 with sulfuric acid. The fermentation broth was produced to obtain hyaluronidas...

Embodiment 2

[0070] Inclined medium composition (100mL): peptone 1.0g, yeast powder 1.0g, K 2 HPO 4 ·3H 2 O 0.1g, MgSO 4 ·7H 2 O 0.1g, glucose 1.0g, agar powder 2g, pH was adjusted to 7.0 with phosphoric acid.

[0071] Composition of seed culture medium (100mL): peptone 1.0g, yeast powder 1.0g, K 2 HPO 4 ·3H 2 O 0.1g, MgSO 4 ·7H 2 O 0.1g, glucose 1.0g, pH was adjusted to 7.0 with phosphoric acid.

[0072] Fermentation medium composition (100mL): peptone 1.0g, yeast powder 1.0g, K 2 HPO 4 ·3H 2 O 0.1g, MgSO 4 ·7H 2 O 0.1g, glucose 1.0g, Tween80 0.05mL.

[0073] Inoculate the slant strain (Bacillus sp. A50 CGMCC NO. 5744) into the sterilized seed culture medium, cultivate at 30°C and 100 rpm for 15 hours, and then inoculate the seed liquid into the sterilized fermentation medium The inoculum was 10%, 35℃, 300rpm culture for 16 hours, the pH was maintained at 7.0 with sulfuric acid during the fermentation process, and the hyaluronidase fermentation broth was obtained by fermentation. The fermentatio...

Embodiment 3

[0075] Inclined medium composition (100mL): peptone 1.5g, yeast powder 1.5g, K 2 HPO 4 ·3H 2 O 0.15g, MgSO 4 ·7H 2 O 0.15g, glucose 1.5g, agar powder 2g, adjust the pH to 8.0 with sulfuric acid.

[0076] Composition of seed culture medium (100mL): peptone 1.5g, yeast powder 1.5g, K 2 HPO 4 ·3H 2 O 0.15g, MgSO 4 ·7H 2 O 0.15g, glucose 1.5g, adjust the pH to 8.0 with sulfuric acid.

[0077] Fermentation medium composition (100mL): peptone 0.5g, yeast powder 1.5g, K 2 HPO 4 ·3H 2 O 0.1g, MgSO 4 ·7H 2 O 0.05g, glucose 1.5g, Tween80 0.05mL.

[0078] The slant strain (Bacillus sp. A50 CGMCC NO. 5744) was inoculated into sterilized seed culture medium, cultivated at 35°C and 200 rpm for 13 hours, and then the seed liquid was inoculated into sterilized fermentation medium The inoculum was 10%, 40°C, 100rpm culture for 12 hours, the pH was maintained at 7.0 with hydrochloric acid during the fermentation process, and the hyaluronidase fermentation broth was obtained by fermentation. The fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com