Anti-counterfeiting identification method by aid of quantum points

An anti-counterfeiting label and quantum dot technology, which is applied in the field of anti-counterfeiting labeling based on the difference in wavelength and emission peak intensity, can solve the problems of complex process, low precision, and narrow anti-counterfeiting range, and achieve large information capacity, good stability, and difficulty in imitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of cadmium selenide (CdSe) quantum dots

[0039] Step 1: Add 0.1mmol of cadmium oxide (CdO) and 0.4mmol of stearic acid (SA) into a three-necked flask, use Schlenk technology, degas and inflate several times, heat to 150°C, and keep for 25min to fully dissolve CdO to Colorless, then cooled to 50 ° C.

[0040] Step 2: Add 1.94 g of tri-n-octylphosphine oxide (TOPO) with a purity greater than 90% and 1.94 g of hexadecylamine (HDA) with a purity greater than 90% into a three-necked flask. Using Schlenk technology, after the water and oxygen are exhausted through the vacuum system, it is heated to 320°C under an argon atmosphere. At this time, use a syringe to quickly inject the stock solution prepared with 1mmol selenium (Se) and 2ml tri-n-butylphosphine (TBP), and quickly cool down to 260°C, keep the reaction for 30min, and finally withdraw the heating device to cool the product to room temperature .

[0041] Step 3: Add chemically pure chlorofor...

Embodiment 2

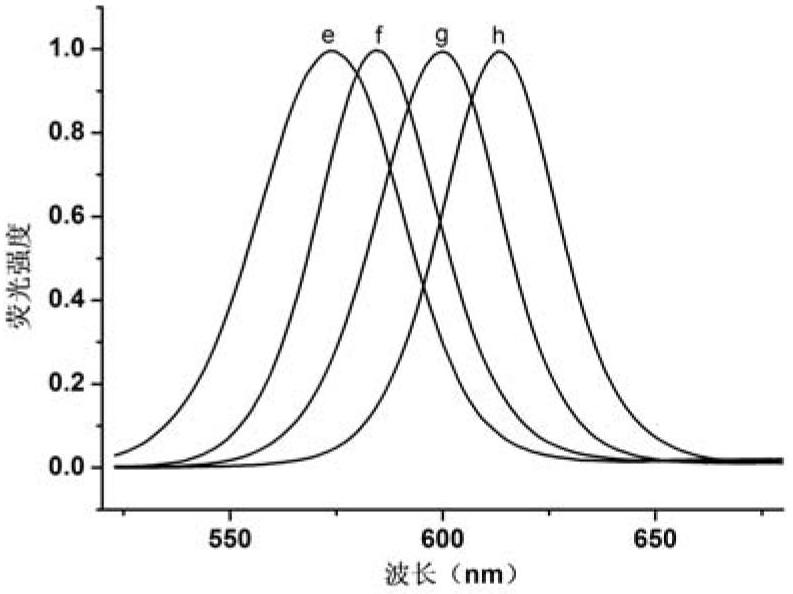

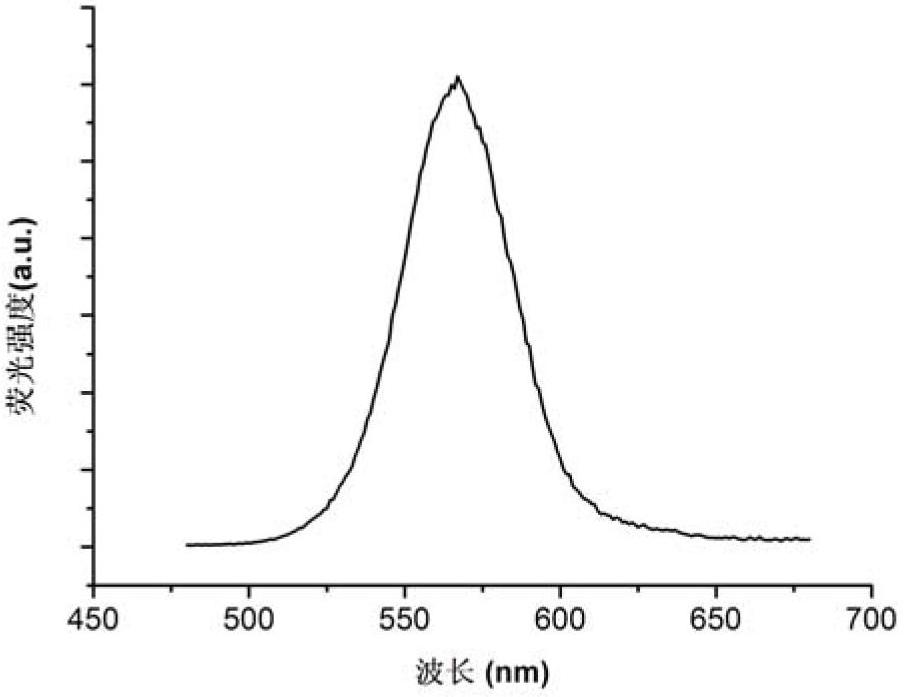

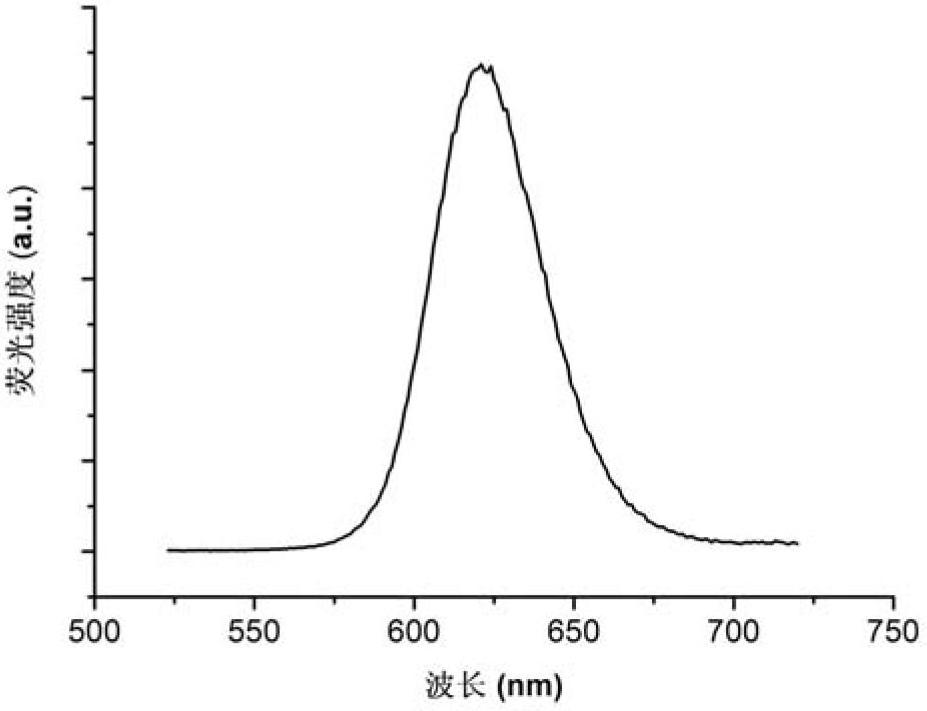

[0045] Two kinds of CdSe quantum dots with different particle sizes A and B are separately excited, and the obtained fluorescence spectrum is as follows figure 2 and image 3 As shown, the central wavelength of quantum dot A is 567nm, and the central wavelength of quantum dot B is 621nm. Two kinds of CdSe quantum dots A and B are mixed in molar percentages of 2:1 and 4:1 respectively, and the fluorescence spectrum of the mixed quantum dot mixture is as follows Figure 4 shown. Depend on Figure 4 It can be seen that after quantum dot A and quantum dot B are mixed in different proportions, the wavelengths of the emission peaks of the two are unchanged, the fluorescence characteristic peaks of each quantum dot can be clearly distinguished, and the emission peak intensity ratio of quantum dots and its mixing ratio exist. Correspondence, and has relative specificity. This shows that after mixing quantum dot materials with different emission wavelengths together, the emission ...

Embodiment 3

[0047] Dissolve CdSe quantum dots of different sizes in chloroform, the particle size of the quantum dots is preferably 2~8nm, make a CdSe chloroform mixture with a mass concentration of 10%, and then impregnate the membrane material (the membrane material has multiple cavities) into In the above mixed solution, the above-mentioned CdSe quantum dots of different sizes are adsorbed in the cavity of the film material, such as Figure 5 As shown, then use this film to make an anti-counterfeit mark, and then load the target product through pasting, packaging, etc. Optical information such as the central wavelength of each quantum dot in the cavity of the membrane material and the luminous intensity of each quantum dot is read by a spectral detection instrument such as a fiber optic spectrometer, and the obtained emission wavelength of each quantum dot and the luminescence of each emission wavelength are read. Intensity ratios are transformed by coding rules. For example: the emis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com