Solid-oxide fuel cell based energy storage cell and preparation method thereof

A solid oxide and fuel cell technology, applied to solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of large system, low energy efficiency, easy sintering into blocks, etc., and achieve long theoretical life and shape change small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The structure prepared by dipping molding method is: NiO-YSZ / SSZ / LSM-SSZ anode-supported tubular solid oxide fuel cell. For the specific preparation process, refer to Example 1 in the specification of Chinese patent CN200810200167.7. The prepared anode-supported tubular solid oxide fuel cell has a wall thickness of about 0.5-0.8 mm, an outer diameter of about 1.0 cm, a length of about 20 cm, and a cathode area of about 15 cm 2 , the volume of the anode chamber is 12.7cm 3 .

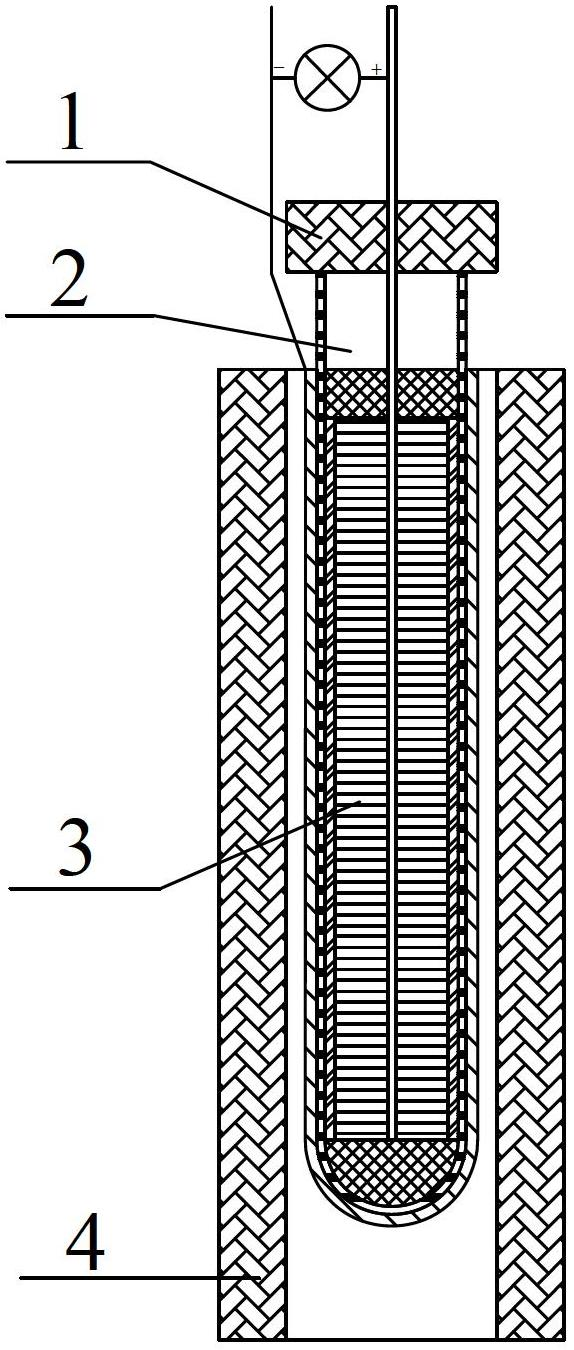

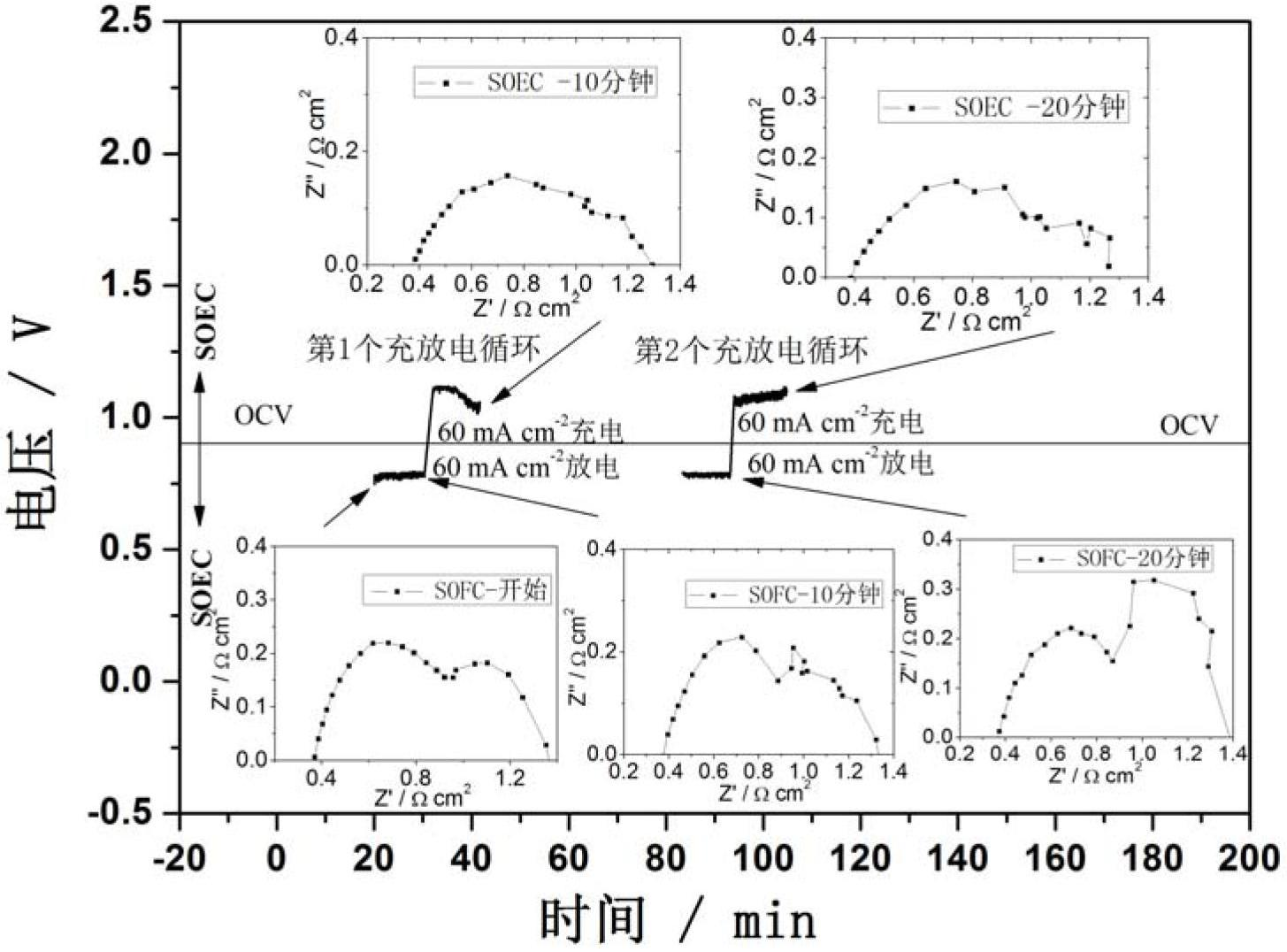

[0052] Such as figure 1 Shown: the above-mentioned anode-supported tubular solid oxide fuel cell 2 is reduced to an open circuit voltage greater than 1.0V in a hydrogen atmosphere, and then lowered to room temperature under the protection of a hydrogen atmosphere, and 0.017mol iron powder, 0.02mol calcium oxide and 0.001g Calcium hydroxide is mixed and filled into the anode chamber 3 of the battery, the air in the anode chamber 3 is vented by introducing hydrogen gas, and then the battery is se...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that the iron powder filled in the anode chamber is replaced by tin powder, and the rest of the content is the same as that described in Embodiment 1.

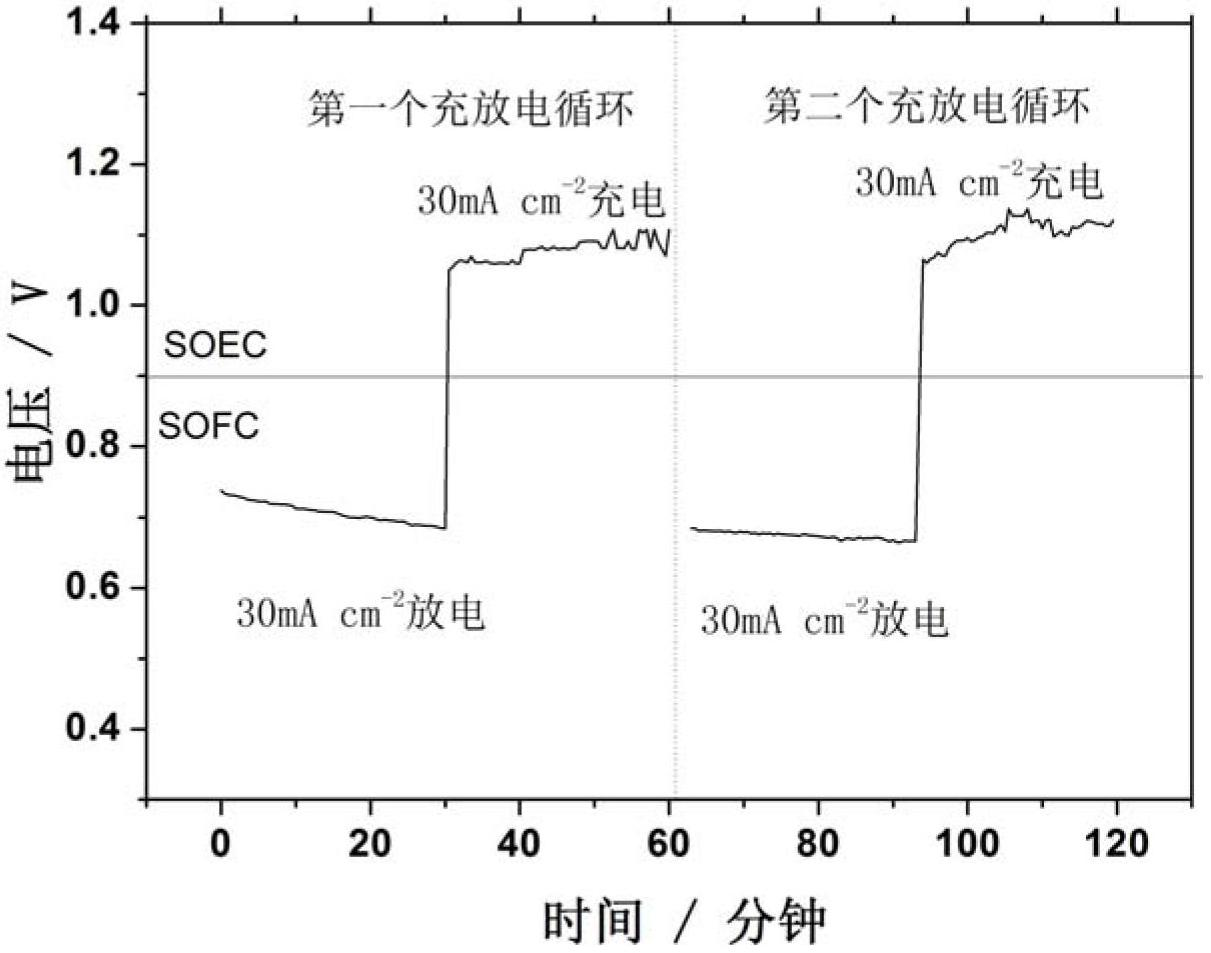

[0057] image 3 The electrical performance curve of the energy storage battery prepared for this example after two charge and discharge cycles, the charge and discharge current density is 30mA / cm 2 , The charge and discharge cycle is 30 minutes. Depend on image 3 It can be seen that the charging and discharging voltage of the battery is relatively stable. combine image 3 It is calculated that the utilization rate of tin is 24.7%, and the energy density generated by the battery is 75.8Wh / kg.

Embodiment 3

[0059] The difference between this embodiment and embodiment 1 is that the calcium oxide filled in the anode chamber is replaced by magnesium oxide, and the calcium hydroxide is replaced by magnesium hydroxide, and the rest of the content is the same as that described in embodiment 1.

[0060] Figure 4 The electrical performance curve of the energy storage battery prepared for this example after two charge and discharge cycles, the charge and discharge current density is 80mA / cm 2 , The charge and discharge cycle is 30 minutes. Depend on Figure 4 It can be seen that the charging and discharging voltage of the battery is relatively stable; after two charging and discharging, the battery performance does not appear to decay. combine Figure 4 It is calculated that the utilization rate of iron reaches 49.4%, and the energy density generated by the battery is 504.2Wh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com