Method for preparing docosahexaenoic acid (DHA) and eicosatetraenoic acid (ARA) emulsion

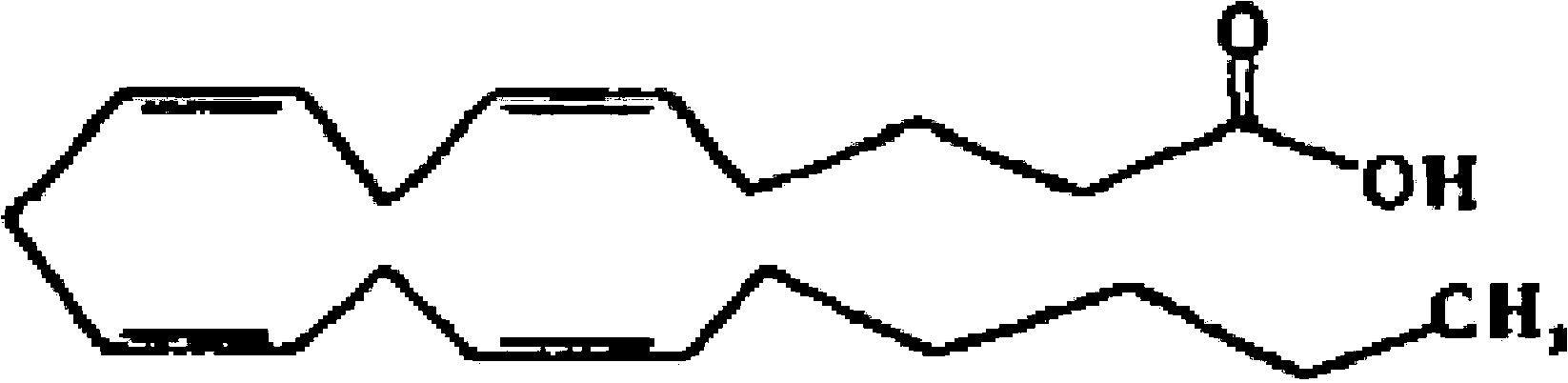

An emulsion and emulsification equipment technology, which is applied in the field of preparation of DHA and ARA emulsions, can solve problems such as easy oxidation, and achieve the effects of preventing fat oxidation, reducing interfacial tension, and improving technical barriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

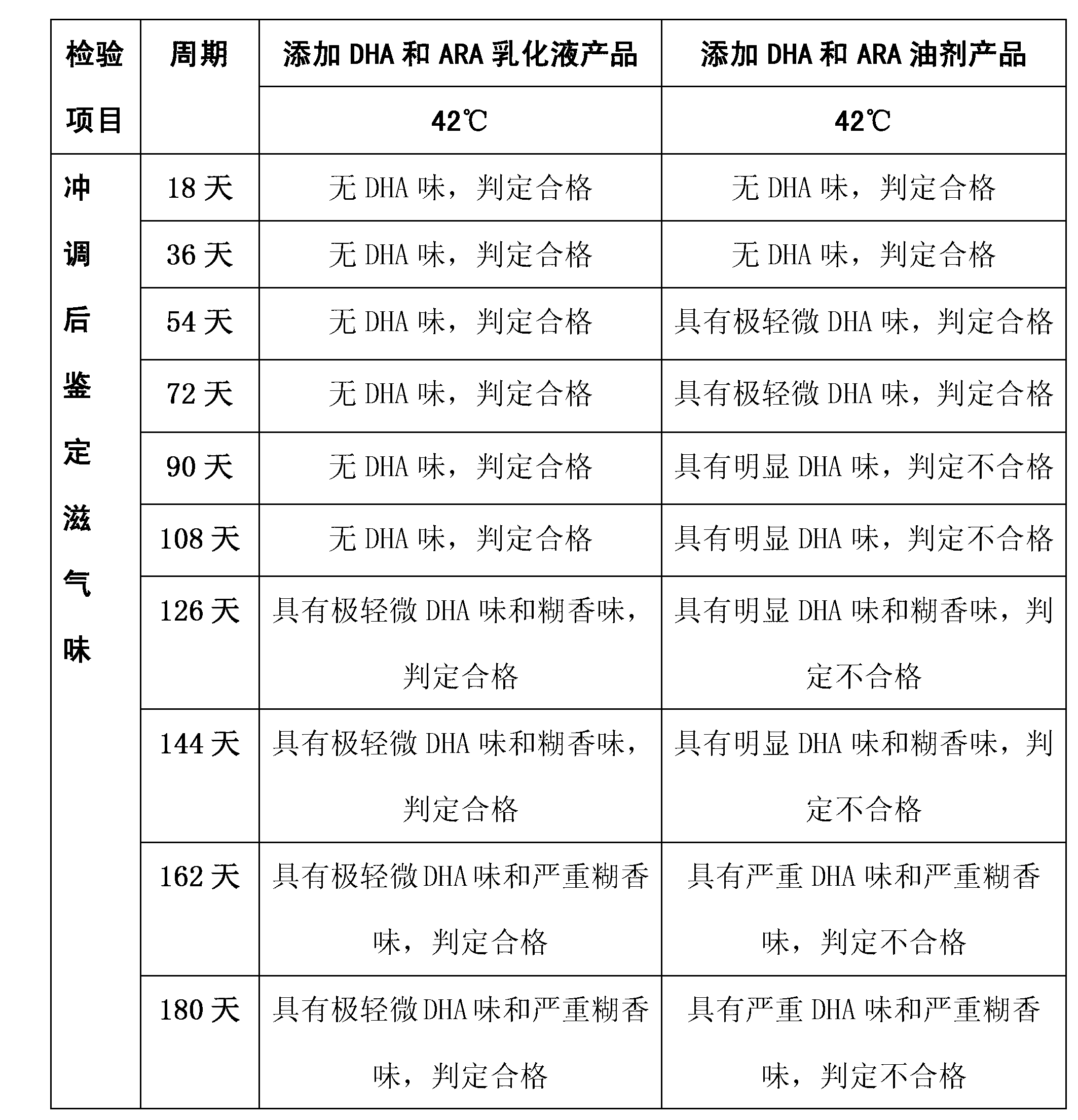

[0017] .A preparation method of DHA and ARA emulsion, comprising the following processes successively: emulsion preparation:

[0018] The emulsion preparation process includes the following three parts: A, B, and C:

[0019] A. Prepare the water phase in the shear emulsification tank of the emulsification equipment: add pure water, heat and keep it warm to 35-65°C, turn on the shear emulsification stirring device, add sodium ascorbate in an amount of 0.1-4.2kg, and then add the emulsifier: The added amount of sodium starch octenyl succinate is 1.6-28 kg, the added amount of sodium caseinate is 0.2-3.5 kg, the added amount of gum arabic is 0.96-16.8 kg, the added amount of concentrated milk protein is 1.6-28.0 kg, the above emulsifier Just add one kind, shearing: Use the shearing head to stir the material at high speed, and shear for 3 to 10 minutes until fully dissolved;

[0020] B. Prepare the oil phase in the oil tank of the emulsification equipment: add vegetable oil in ...

Embodiment 1

[0027] Taking the production of one ton of milk powder as an example, the ingredients are as follows:

[0028] 1. Amount of fortifier (DHA oil): 0.15~3.0kg.

[0029] 2. Amount of enhancer (ARA grease): 0.15~3.0kg.

[0030] 3. Addition amount of emulsifier (starch sodium octenyl succinate): 1.6~28.0kg.

[0031] 4. Addition amount of antioxidant (ascorbyl palmitate): ≤0.2g / kg.

[0032] 5. Antioxidant (sodium ascorbate) dosage: 0.26~4.2kg.

[0033] 6. Antioxidant (vitamin E) addition amount: Add appropriate amount according to production needs.

[0034] 7. Addition amount of vegetable oil (walnut oil, soybean oil, corn oil, palm oil): 0.5~8.0kg.

[0035] 8. Optimum ratio: By comparing the oven method and the water bath method, it is determined that starch sodium octenyl succinate: DHA and ARA oil = 2: 1, the emulsification effect is the best.

Embodiment 2

[0037] Taking the production of one ton of milk powder as an example, the ingredients are as follows:

[0038] 1. Amount of fortifier (DHA oil): 0.15~3.0kg.

[0039] 2. Amount of enhancer (ARA grease): 0.15~3.0kg.

[0040] 3. Addition amount of emulsifier (sodium caseinate): 0.2~3.5kg.

[0041] 4. Addition amount of antioxidant (ascorbyl palmitate): ≤0.2g / kg.

[0042] 5. Antioxidant (sodium ascorbate) dosage: 0.1~1.2kg.

[0043] 6. Antioxidant (vitamin E) addition amount: Add appropriate amount according to production needs.

[0044] 7. Addition amount of vegetable oil (walnut oil, soybean oil, corn oil, palm oil): 0.5~8.0kg.

[0045] 8. Optimum ratio: By comparing the oven method and the water bath method, it is determined that sodium caseinate: DHA and ARA oil = 1:4, and the emulsification effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com