Preparation method of hollow boron/cerium co-doped nanometer titanium dioxide fiber material

A nano-titanium dioxide and fiber material technology, applied in the field of photocatalyst preparation, can solve the problems of easy loss of nano-titanium dioxide particle suspension system, reduced catalyst surface area, low photocatalytic activity, etc., to avoid catalyst loss, easy solid-liquid separation, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

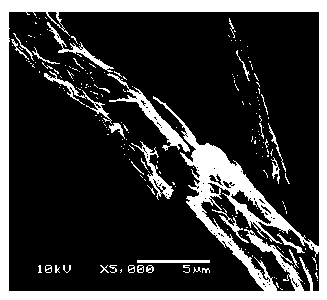

Embodiment 1

[0026] At room temperature, in a 500 mL three-neck flask equipped with a magnetic stirrer and a dropping funnel, add 20 mL of tetrabutyl titanate dissolved in 40 mL of absolute ethanol, add 10 mL of acetylacetone and 15 mL of ice Acetic acid, then add a mixture of 80 mL absolute alcohol and 15 mL water containing 0.05 g boric acid and 0.33 g cerium ammonium nitrate at a rate of 1 drop / second, continue stirring for 2 h after the dropwise addition, and let stand for 48 h. Weigh 5 g of the pretreated absorbent cotton thread and put it into the prepared 150 mL TiO 2 After soaking in the sol for 48 h, the solvent was evaporated to dryness at 80 °C, dried for 12 h, and then baked in a muffle furnace at 500 °C for 2 h under the protection of nitrogen to obtain an average pore diameter of 22 nm and a specific surface area of 230 m 2 / g boron, cerium co-doped nano titanium dioxide hollow fiber material.

[0027] A UV lamp (275 nm) with a power of 20 W was used as the light source to...

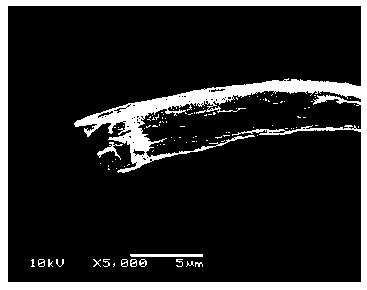

Embodiment 2

[0029] At room temperature, in a 500 mL three-neck flask equipped with a magnetic stirrer and a dropping funnel, add 20 mL of tetrabutyl titanate dissolved in 40 mL of absolute ethanol, add 10 mL of acetylacetone and 15 mL of ice Acetic acid, then add a mixture of 80 mL absolute alcohol and 15 mL water containing 0.12 g triethyl borate and 0.26 g cerium nitrate at a rate of 1 drop / second, continue stirring for 2 h after the dropwise addition, and let stand for 48 h. Weigh 5 g of the pretreated absorbent cotton thread and put it into the prepared 150 mL TiO 2 After immersing in the sol for 48 h, the solvent was evaporated to dryness at 80 °C, dried for 12 h, and then calcined at 500 °C for 2 h in a muffle furnace under the protection of nitrogen to obtain an average pore diameter of 20 nm and a specific surface area of 238 m 2 / g boron, cerium co-doped nano titanium dioxide hollow fiber material.

[0030] A UV lamp (275 nm) with a power of 20 W was used as the light source t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com