Preparation of steel-slag-based inorganic polymer-zinc oxide semiconductor composite catalyst and application of steel-slag-based inorganic polymer-zinc oxide semiconductor composite catalyst in degradation of dyeing wastewater

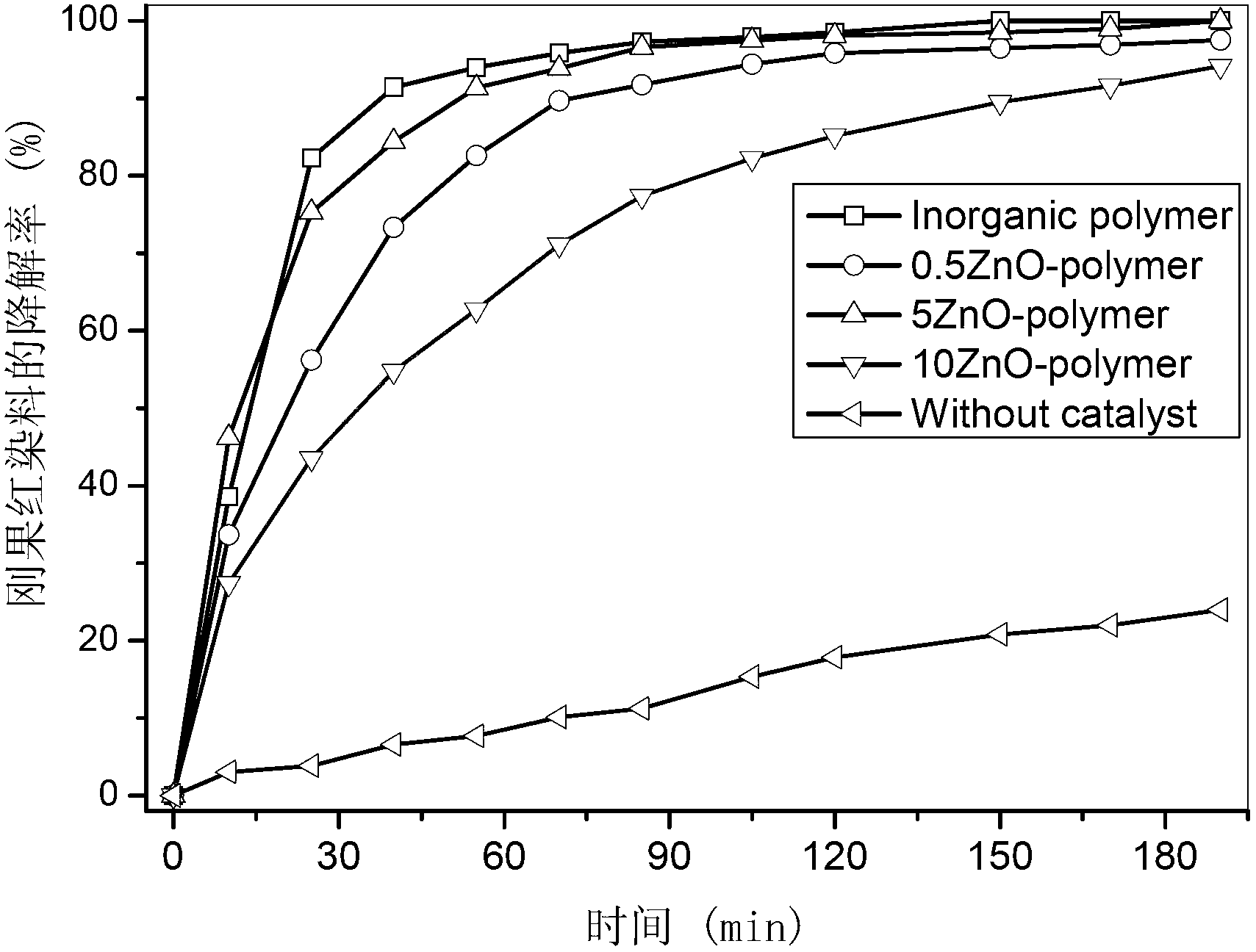

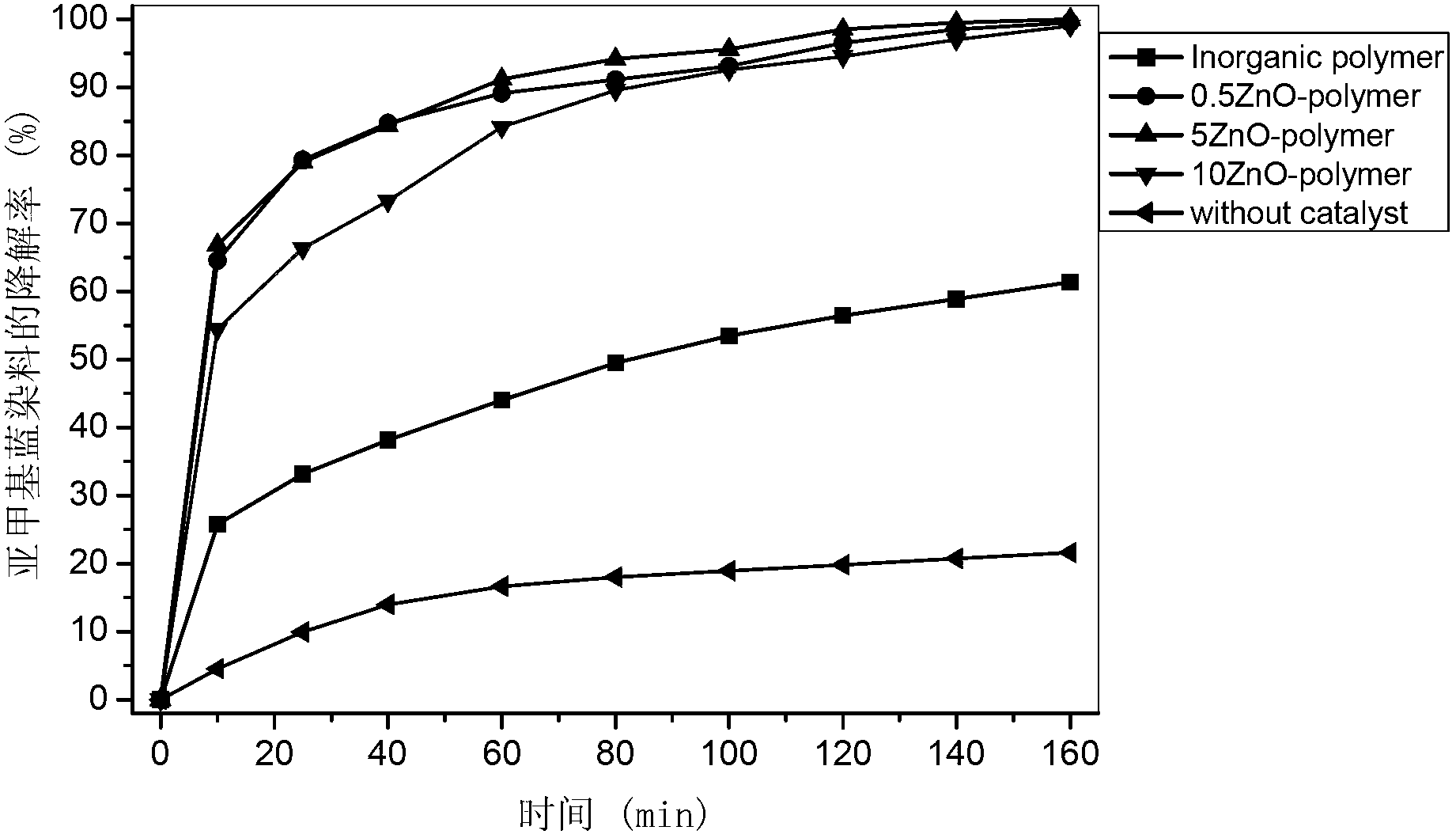

A technology of inorganic polymers and composite catalysts, applied in physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, water pollutants, etc., can solve the problem of steel slag-based inorganic polymer-oxide semiconductors not found Problems such as literature and patent reports on dye degradation prepared by composite catalyst, to achieve the effect of simple and easy process, mild degradation conditions and short degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

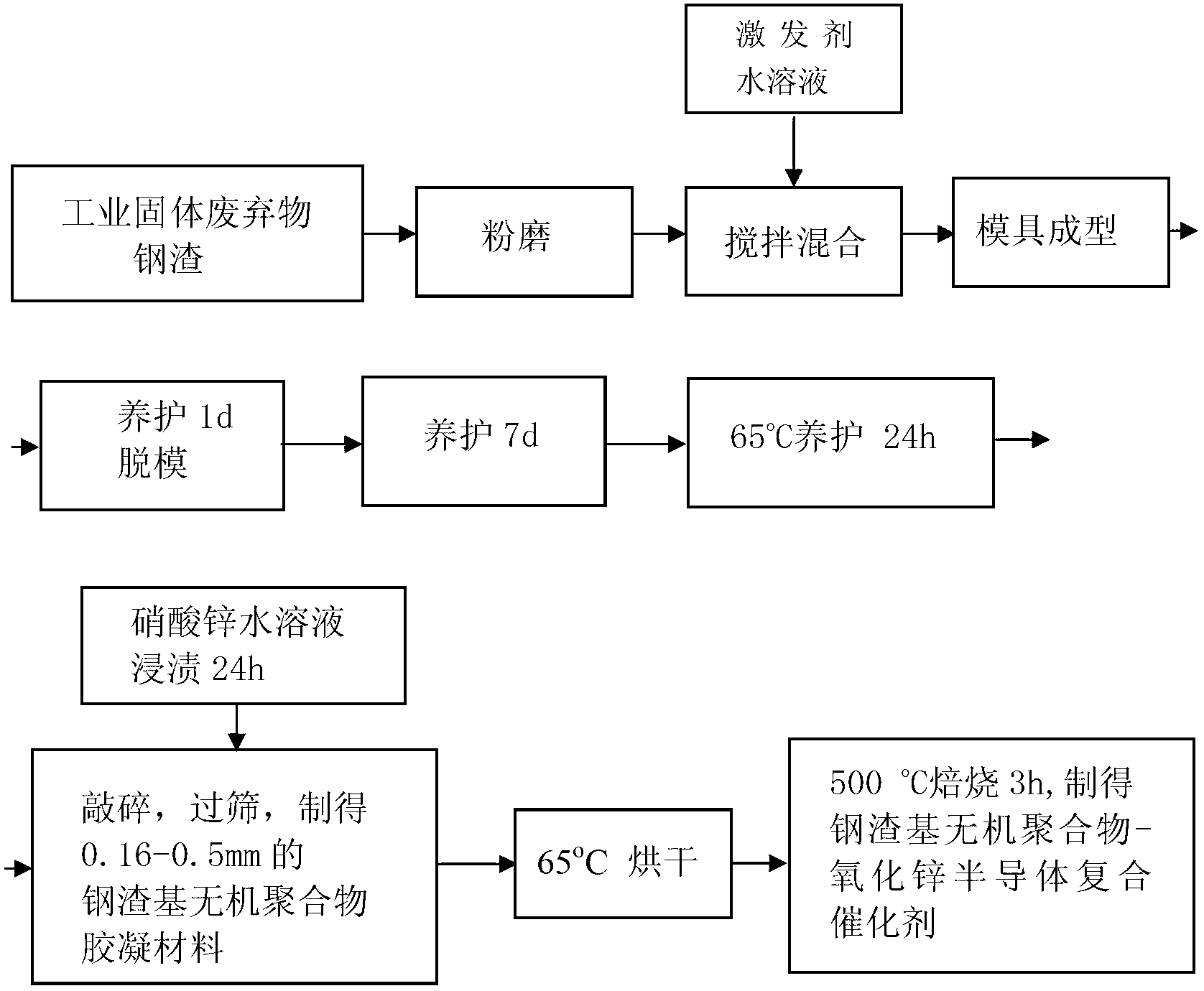

Method used

Image

Examples

Embodiment 1

[0047] Accurately weigh 1500g of steel slag raw material, take this as the measurement basis (100%), adopt the external mixing method, the dosage of chemical activator sodium silicate is 11% of the weight of steel slag, the mass ratio of water to steel slag (also called water slag ratio ) is 0.28. Pour the steel slag powder into a double-rotation and double-speed slurry mixer for stirring and dispersing; add the sodium silicate aqueous solution and stir at a high speed to form a uniformly mixed slurry; put the slurry into a triple mold of 40mm×40mm×160mm, Vibrate on a mortar vibrating table, and scrape it flat with a scraper to obtain a formed slurry test block. Put the formed test block into a standard curing box for 1 day of curing, then remove it from the mold, put it in a curing room for 7 days at room temperature, then put it into a sealed plastic bag, and then cure it at 65°C for 24 hours. The compressive strength of the test block is 25MPa , The flexural strength is 2....

Embodiment 2

[0050] All operation steps are identical with embodiment 1, just take by weighing solid Zn(NO 3 ) 2 ·6H 2 The amount of O was changed to 7.345 g and dissolved in 20 mL of distilled water; a steel slag-based inorganic polymer-zinc oxide semiconductor composite catalyst (labeled 5ZnO-polymer) with a theoretical loading of ZnO of 5% was obtained.

Embodiment 3

[0052] All operation steps are identical with embodiment 1, just take by weighing solid Zn(NO 3 ) 2 ·6H 2 The amount of O was changed to 14.69 g and dissolved in 20 mL of distilled water; an inorganic polymer-zinc oxide semiconductor composite catalyst (marked as 10ZnO-polymer) with a theoretical loading of ZnO of 10% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com