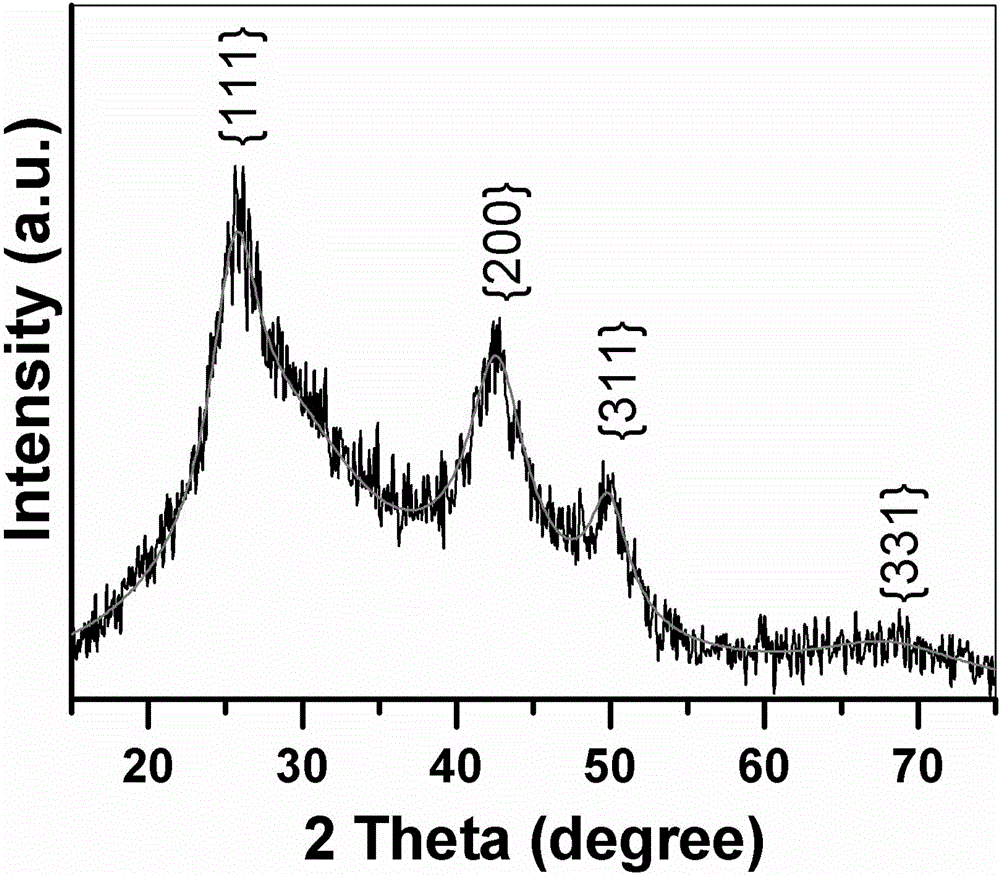

Preparation method of nanometer cadmium selenide sulfide material

A technology of cadmium selenide and nano-sulfur, applied in the direction of nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of lack of water solubility and biocompatibility, unbelievable combination of two kinds of nanoparticles, adjustable preparation, difficult to grasp, etc. Problems, to achieve good water solubility and biocompatibility, safe and stable preparation process, easy to master the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 0.0154g of sodium selenite, add 2ml of deionized water to dissolve, then add 20ml of glycerin and stir to dissolve to obtain a selenite solution; weigh 1.0078g of glucose and add 2ml of water to dissolve;

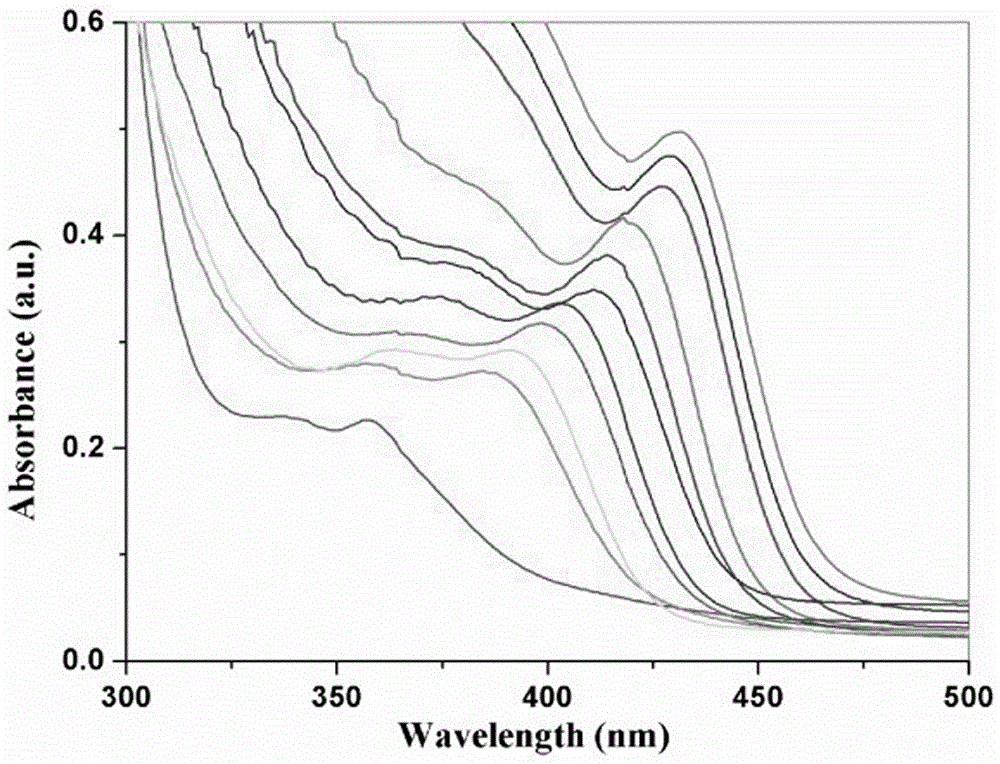

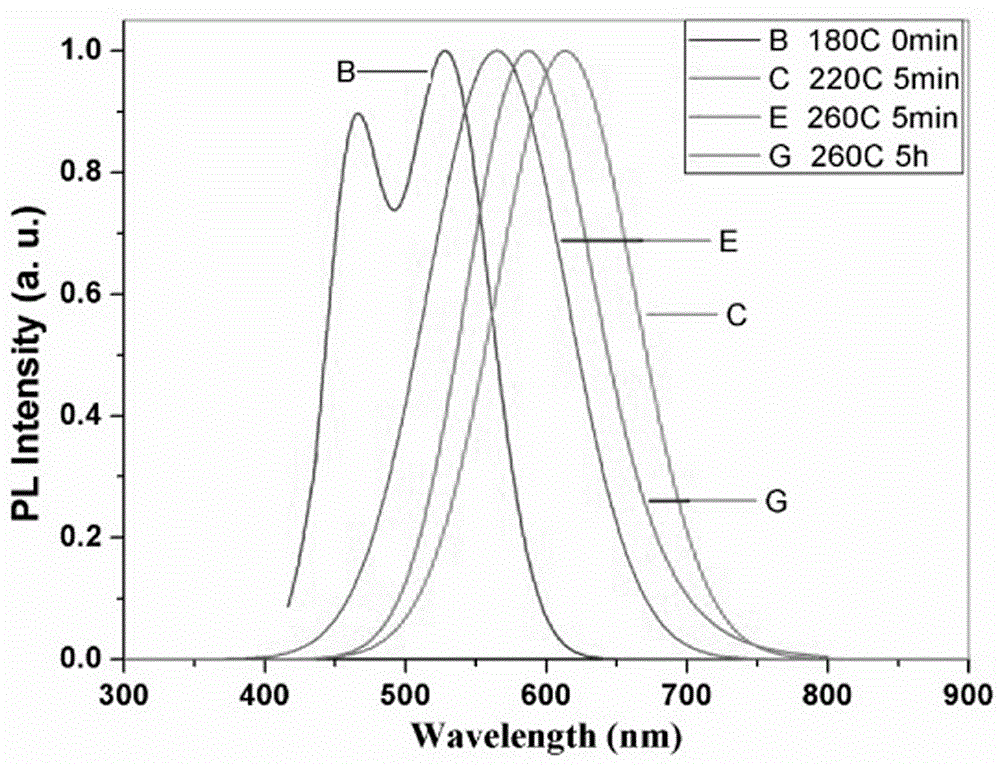

[0025] After heating the obtained sodium selenite solution to 80°C, add glucose solution and 1ml stabilizer MPA, and heat to 160°C, during which the solution gradually changes from colorless to light yellow, orange, light red, dark red suspension, when When the temperature rises to 220°C, the solution becomes colorless, and after cooling to room temperature, black suspended matter appears in the solution, add 10ml of water to dissolve and dilute, then heat to 260°C, when the solution becomes colorless, cool to room temperature, and selenium can be obtained Precursor solution;

[0026] Weigh CdCl 2 ×2.5H 2 O 0.0211g, polyethylene glycol 0.2166g, add 15ml of deionized water, stir and dissolve at 60°C, add 0.1ml of MPA, add 10ml of sodium hydroxide solution (1mo...

Embodiment 2

[0029] Weigh 0.0243g of sodium sulfide crystals, add 10ml of deionized water to dissolve, then add 20ml of glycerin and 1ml of MPA and stir evenly to obtain a sulfur precursor solution;

[0030] Weigh CdCl 2 *2.5H 2 O 0.0203g, polyethylene glycol 0.2038g, add 10ml of deionized water, stir and dissolve at 60°C, add 0.1ml of MPA, add 15ml of sodium hydroxide solution (1mol / L), adjust the pH to 11, and obtain the cadmium precursor solution;

[0031]After the prepared cadmium precursor solution was heated to 100°C, the prepared sulfur precursor solution was gradually added dropwise, and then the temperature was gradually raised to 260°C, during which the color of the solution changed from light yellow to yellow-green. The nano-CdS solution can be obtained by incubating for 15 minutes, and centrifuged at 12,000 rpm for 30 minutes to obtain water-soluble and biocompatible nano-CdS powder.

Embodiment 3

[0033] Weigh 0.0078g of sodium selenite, add 2ml of deionized water to dissolve, then add 10ml of glycerin and stir to dissolve to obtain a selenite solution; weigh 0.1528g of glucose and add 2ml of water to dissolve;

[0034] Heat the dissolved sodium selenite solution to 80°C, add glucose solution and 1ml stabilizer MPA, and heat to 160°C, during which the solution gradually changes from colorless to light yellow, orange, light red, deep red suspension, When the temperature rises to 220°C, the solution becomes colorless, and after cooling to room temperature, a black suspension appears in the solution, add 10ml of water to dissolve and dilute, then heat to 260°C, when the solution becomes colorless, cool to room temperature, and you can get Selenium precursor solution;

[0035] Weigh 0.0108g of sodium sulfide crystals, add 5ml of deionized water to dissolve, then add 10ml of glycerin and 0.5ml of MPA and stir evenly to obtain the sulfur precursor solution;

[0036] Weigh 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com