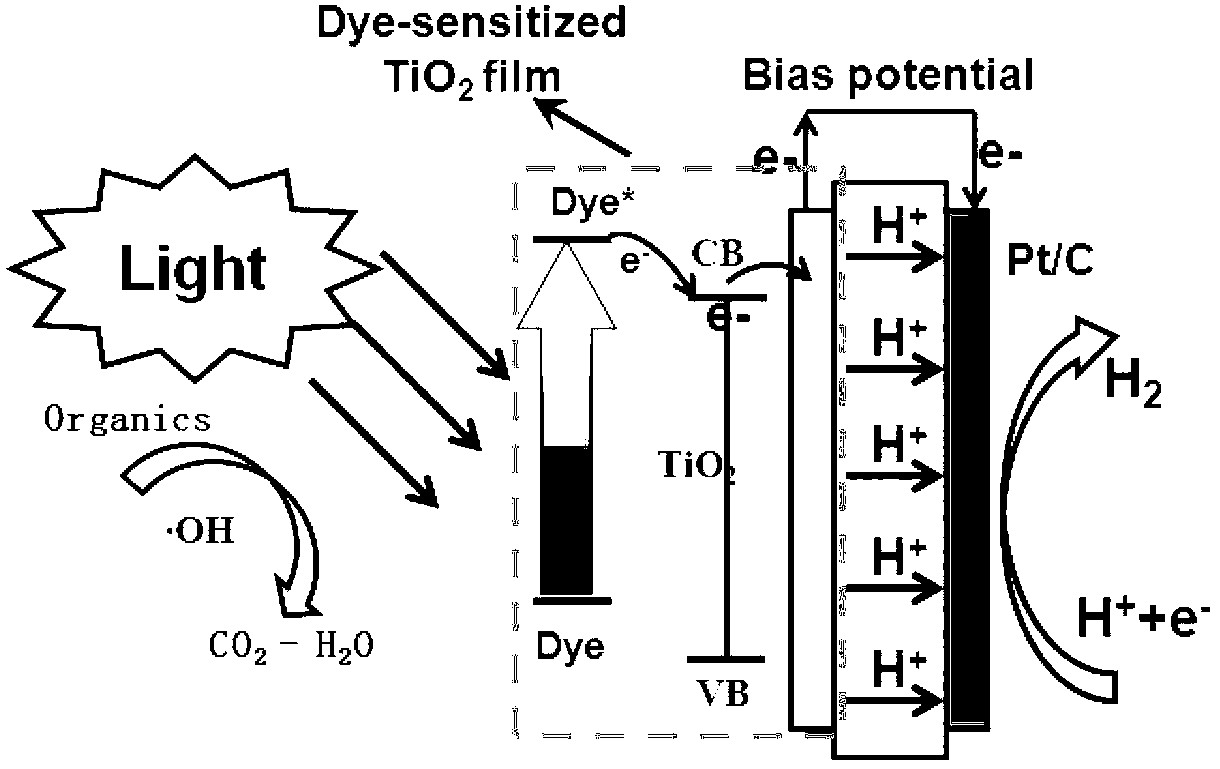

Method for producing hydrogen by using dye-sensitized photocatalytic fuel cell and degrading organic dye wastewater simultaneously

An organic dye and dye sensitization technology, which is applied in the field of simultaneous hydrogen production to achieve the effects of improving degradation efficiency, solving environmental pollution and energy shortage, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

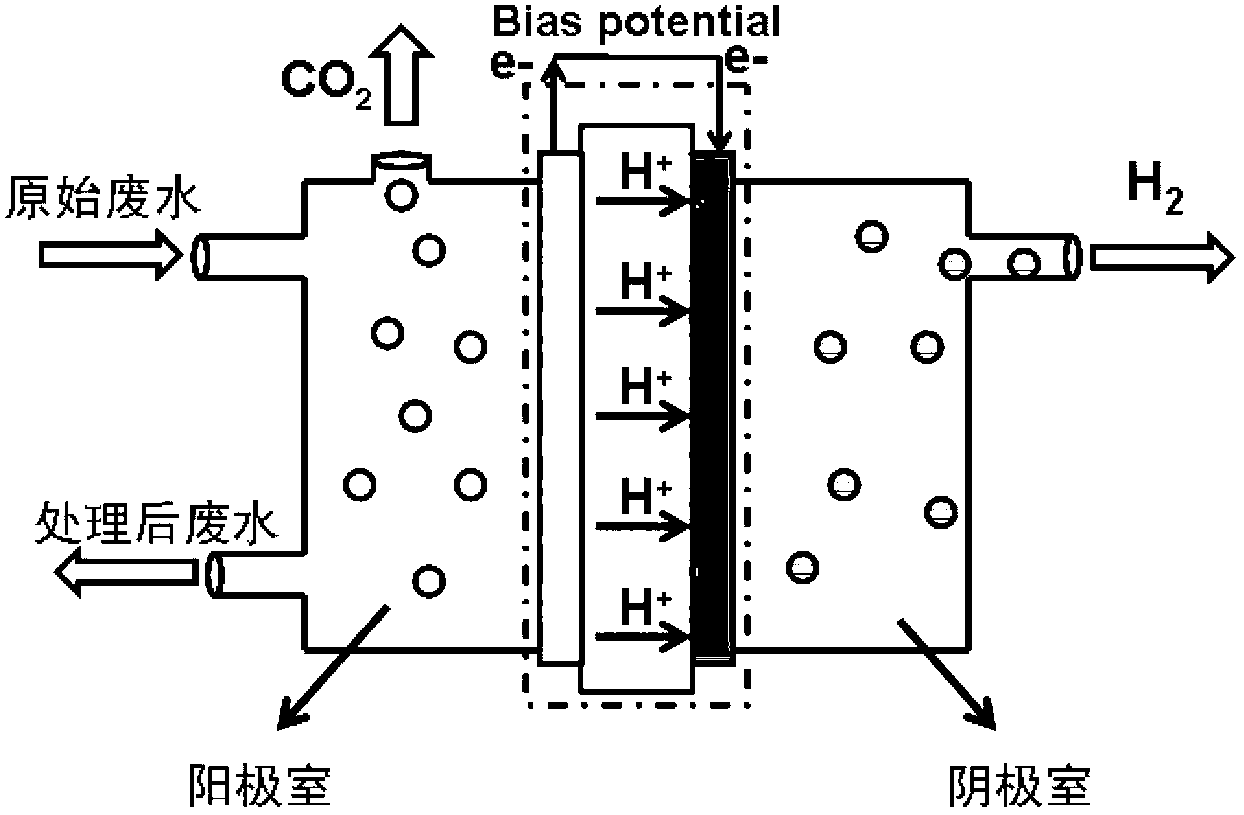

preparation example Construction

[0045] (1) Preparation of PFC electrode

[0046] The photoanode can be prepared by preparing a photocatalyst nano-film on the carrier; the cathode is mainly prepared by loading the Pt / C catalyst on the conductive porous material; the proton exchange membrane needs to be pretreated to selectively permeate protons.

[0047] The photoanode carrier can be made of sheet or mesh conductive materials, such as titanium plate, conductive nickel mesh, carbon fiber cloth or carbon paper, FTO, ITO glass and other materials.

[0048] Photoanode catalysts are characterized by porous semiconductor materials (such as TiO 2 , ZnO, WO 3 , SnO 2 Wait).

[0049] The above-mentioned photocatalyst is prepared on a solid carrier, including the selection of immobilization techniques such as sol-gel method, liquid phase deposition method, vapor phase deposition method, magnetron sputtering method, etc., and the optimization of heat treatment temperature to achieve a firm combination of the catalyst...

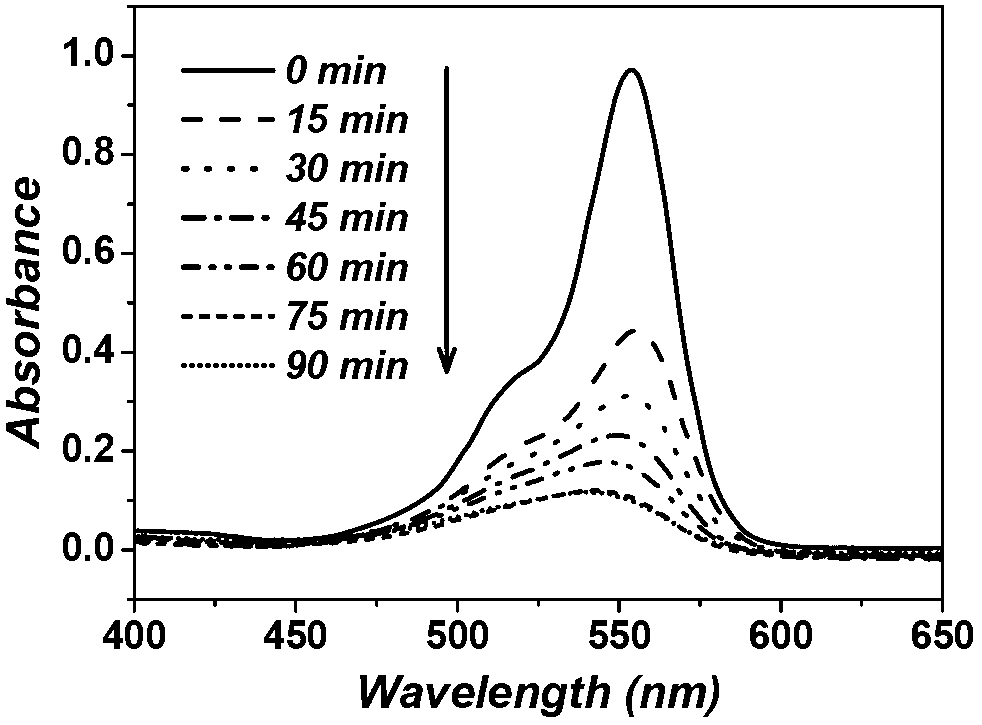

Embodiment

[0058] (1) Preparation of PFC photoanode:

[0059] 10ml concentrated H 2 SO 4 Add dropwise into 50ml of deionized water, stir with a magnetic stirrer for 5 minutes, add 1mL of tetrabutyl titanate dropwise, and stir for 5 minutes. Put the prepared solution into a 100ml high-pressure reaction kettle with a polytetrafluoroethylene liner, and place the cleaned FTO glass substrate in the reaction kettle with the conductive film facing down. Then the reaction kettle was put into a drying oven and heated to 150°C for reaction, and the temperature was kept for 16 hours. After the reaction, cool down to room temperature naturally, take out the FTO glass, rinse it repeatedly with deionized water, then dry it naturally in the air, put it into a muffle furnace for heat treatment at 450 °C for 1 h, and obtain TiO 2 Nanocrystalline array films.

[0060] The above TiO 2 The nanocrystalline array film was placed in a medium-high pressure reactor containing 60ml of NaOH solution with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com