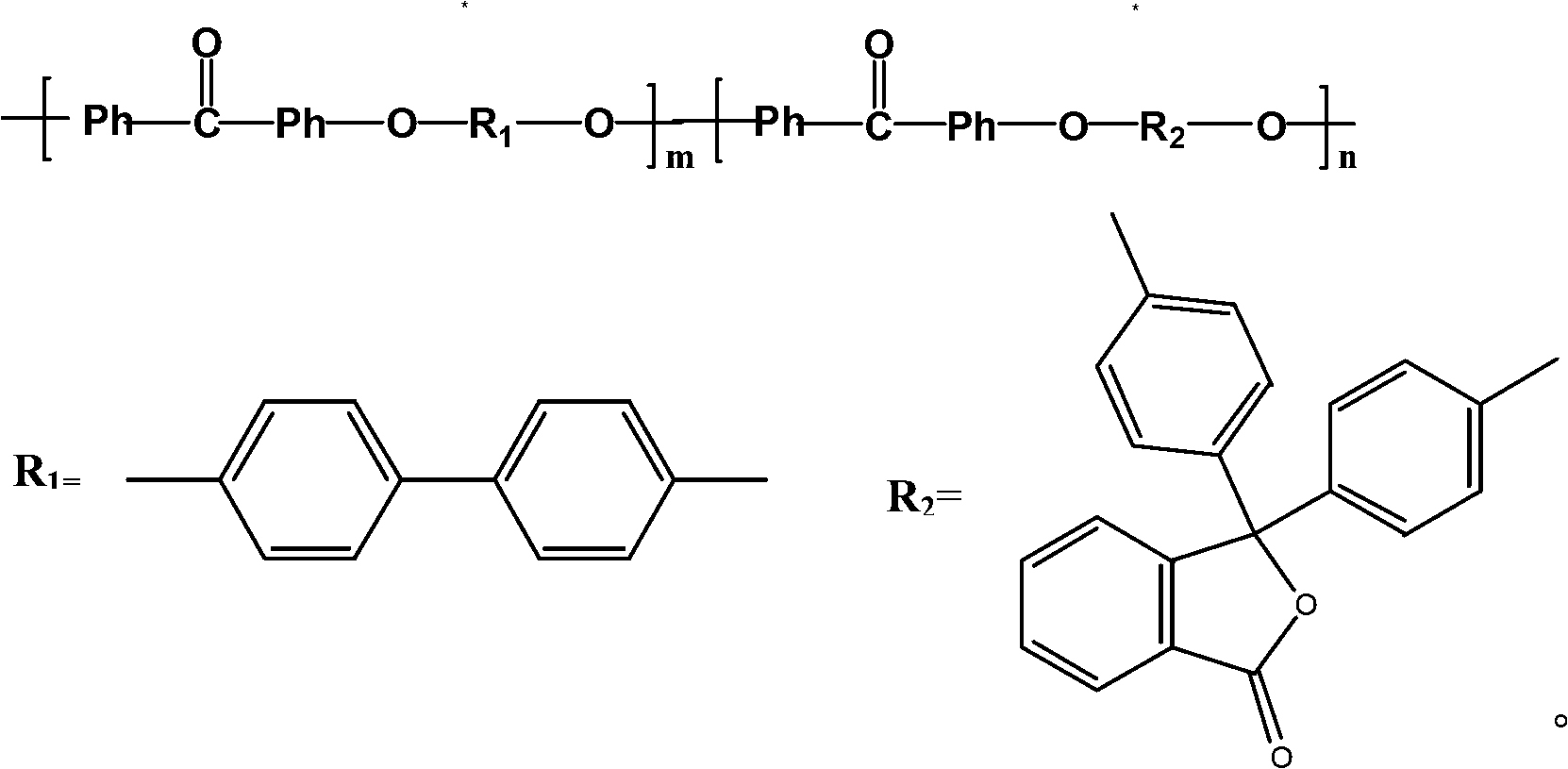

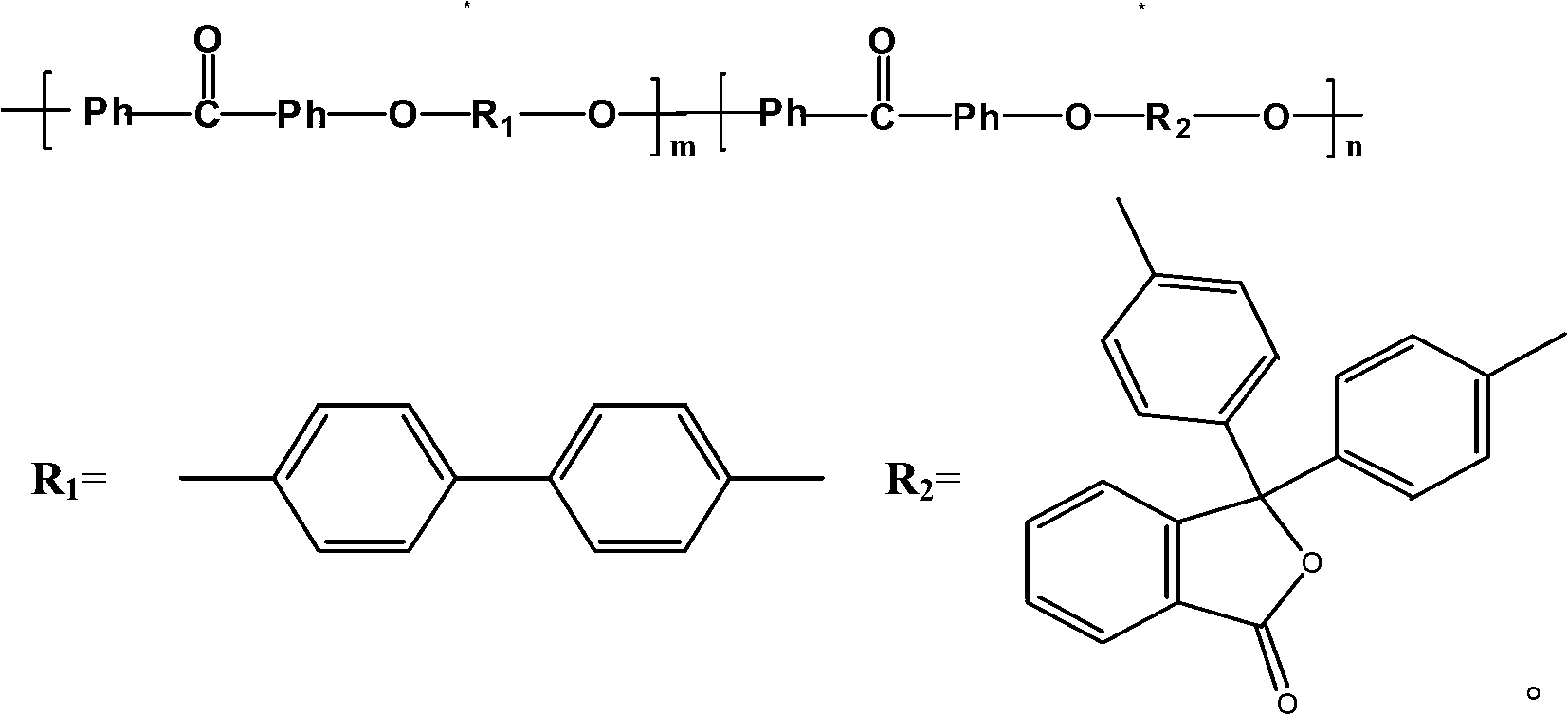

Soluble polyaryletherketone and preparation method thereof

A polyaryl ether ketone and aromatic ring technology, applied in the field of engineering polymer material science, can solve the problems of poor solubility and low glass transition temperature, achieve small linear expansion coefficient, high modulus, and solve problems with poor solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

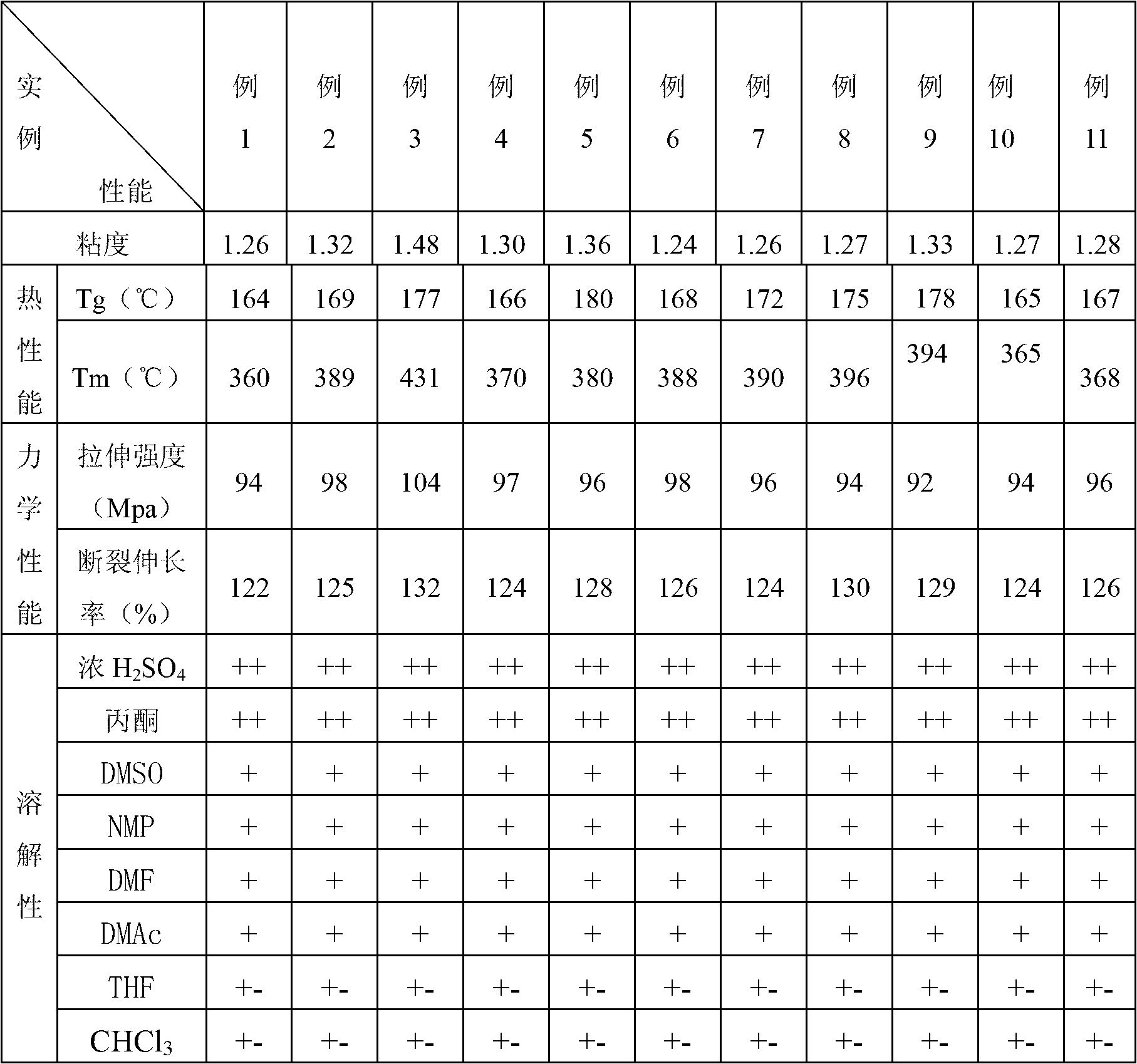

Embodiment 1

[0033] Under the protection of nitrogen, in the reactor equipped with mechanical stirrer, thermometer and condenser, add 261.6 grams of diphenyl sulfone (1.2 moles) and 36 grams of sulfolane (0.3 moles), heat to 60 ℃ after it dissolves, Add 218 grams of 4,4'-difluorobenzophenone (1.0 mol), heat to 80°C to dissolve it, add 169.07 grams of biphenol (0.909 mol), and heat to 120°C to dissolve it, 28.94 grams of phenolphthalein ( 0.091 moles), heated to 150°C to dissolve, and 102.1 grams (0.951 moles) of Na 2 CO 3 and 6.762 g (0.049 mol) K 2 CO 3 Quickly add to the reaction system, stir for 20 minutes to form a salt with diphenol and dissolve, quickly raise the temperature of the system to 180°C, and after 20 minutes of reaction, slowly raise the temperature to 240°C, react for 1 hour, and quickly rise to Increase the temperature to 260°C, and immediately add 4.65 grams of biphenol (0.01 mol) as a chain extender, increase the stirring speed for 1 hour, stop heating, and finally ...

Embodiment 2

[0035] Under the same reaction conditions as in Example 1, the molar ratio of 4,4'-difluorobenzophenone and (biquinone and phenolphthalein) during the first addition was 1: 1.2, and other conditions remained unchanged, namely When charging for the first time, biphenol was 202.74 grams (1.09 moles), and phenolphthalein was 34.66 grams (0.109 moles). The experimental results are shown in Table 1.

Embodiment 3

[0037] Under the same reaction conditions as in Example 1, the molar ratio of 4,4'-difluorobenzophenone and (biquinone and phenolphthalein) during the first addition was 1: 1.5, and other conditions remained unchanged, namely When charging for the first time, biphenol was 252.96 grams (1.36 moles), and phenolphthalein was 43.25 grams (0.136 moles). The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com