Deposition method of salicide bolck film

A metal silicide and deposition method technology, applied in the field of microelectronics, can solve the problems of fast wet etching rate, poor film quality, difficult to control, etc., and achieve the effects of enhanced performance, good film quality, and increased process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The silicon dioxide thin film deposition method provided by the invention reduces the hydrogen content in the thin film, increases the density of the thin film, and improves the quality of the thin film.

[0024] In the following, the deposition method provided by the present invention will be further described in detail through examples, so as to better understand the invention of the invention, but the content of the examples does not limit the scope of protection of the invention.

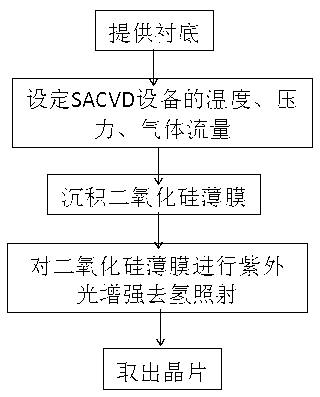

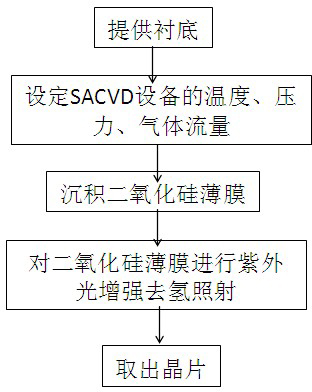

[0025] figure 1 It is a flow chart of the process of depositing silicon dioxide thin film. First, the substrate is provided, and various parameters of the equipment for sub-atmospheric pressure chemical vapor deposition, such as gas flow, pressure and temperature, are set. Preferably, the deposition process of the subatmospheric pressure chemical vapor deposition method has a pressure range of 10-700 torr and a temperature range of 300-500°C. The deposition thickness of the silicon dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com