Method for accurately determining zirconium and hafnium components in zirconium compound by using extraction spectrophotometric method

A zirconium compound and photometric technology, which is applied in the direction of material analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, can solve the problem of high testing costs for instruments and equipment, and reduce testing costs. The effect of high sensitivity and easy operation of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

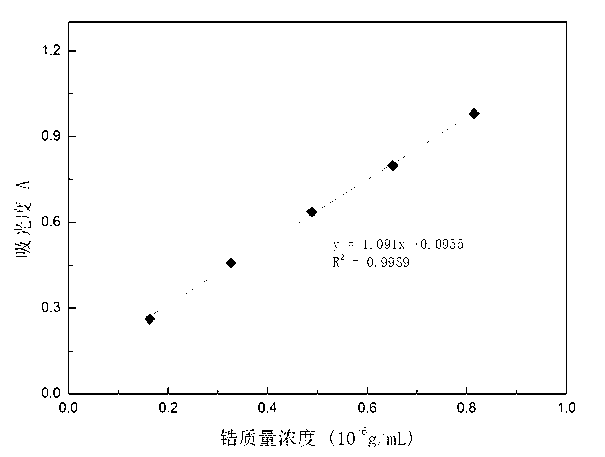

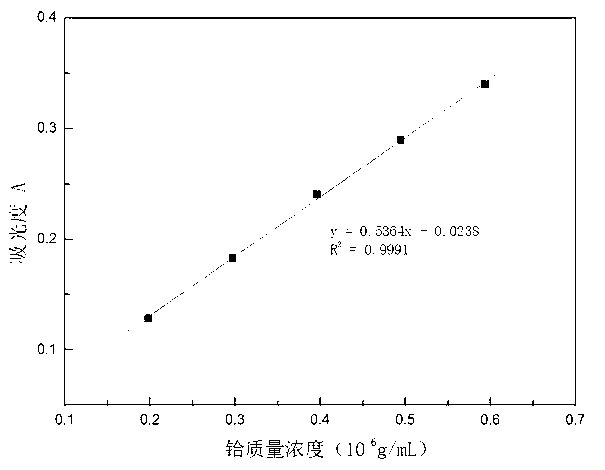

[0030] Step (1): Drawing of standard curves for zirconium and hafnium: prepare 1.0×10 -5 mol / L atomic level zirconium standard solution and hafnium standard solution, add 0.500mL, 0.750mL, 1.000mL, 1.250mL, 1.500mL zirconium standard solution and hafnium standard solution into two sets of 25mL volumetric flasks respectively, then add 4.0 mL 0.10 %(wt) arsenazo III solution for color development of zirconium and hafnium, then add 4.0 mL 5.0% (wt) urea solution for stable color development, add 8.0 mol / L nitric acid to the scale of the volumetric flask for color development environment, and take another blank The sample was used as the background, and after 1.0 h of color development, the absorbance was measured with a UV spectrometer. The absorbance of the solution after color development was measured at 665±5 nm. The mass concentration of zirconium and hafnium was taken as the abscissa, and the absorbance was taken as the ordinate to draw zirconium. and hafnium standard curve...

Embodiment 2

[0040] Step (1): The drawing of the standard curves of zirconium and hafnium is the same as the step (1) in Example 1.

[0041] Step (2): Mix MIBK and 3.0 mol / L HSCN at a volume ratio of 1:1, saturate for 15.0 min at an interface stirring speed of 200 r / min, separate the liquid, and use the upper organic phase as the extraction agent; accurately weigh 3.00 g zircon sand, decompose by sintering with sodium hydroxide, wash, leach zirconium and hafnium with hydrochloric acid, add 22.840 g ammonium thiocyanate, and dilute to 100 mL of feed solution as the extraction water phase.

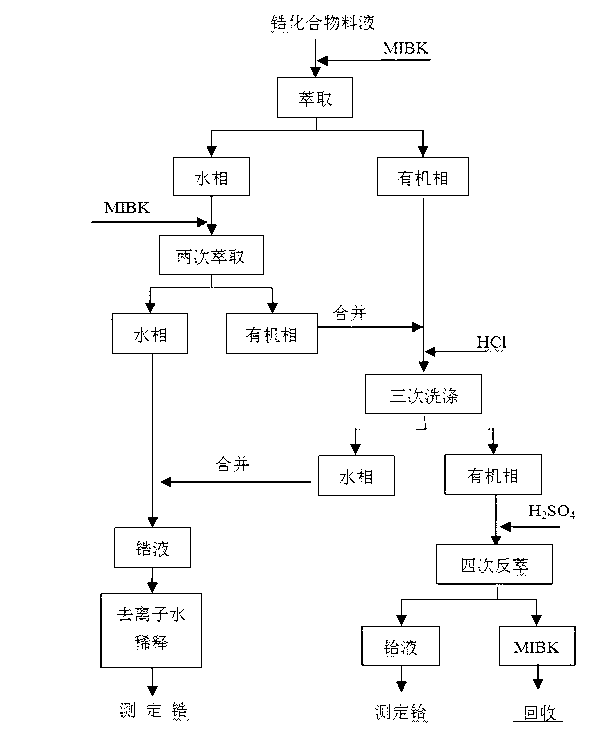

[0042] Step (3): According to the volume ratio: extraction agent: tested material liquid: washing liquid: stripping liquid = 7: 3: 1: 2, take 5.0 mL of the material liquid in the separatory funnel, add the extraction agent, and shake for 3 Min, liquid separation, the raffinate aqueous phase was extracted twice with fresh saturated HSCN MIBK, the organic phases after three extractions were combined, washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com