Resin-sheet-covered metal laminate and manufacturing method therefor

A metal lamination and resin sheet technology, applied in metal lamination products, synthetic resin lamination products, chemical instruments and methods, etc. The effect of improving weather resistance and improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0228] In order to demonstrate this invention more concretely and in detail, an Example is shown below, However, this invention is not limited at all by these Examples. The measurement standards and test methods for the physical properties of the resin sheet-coated metal laminates shown in Examples and Comparative Examples are as follows.

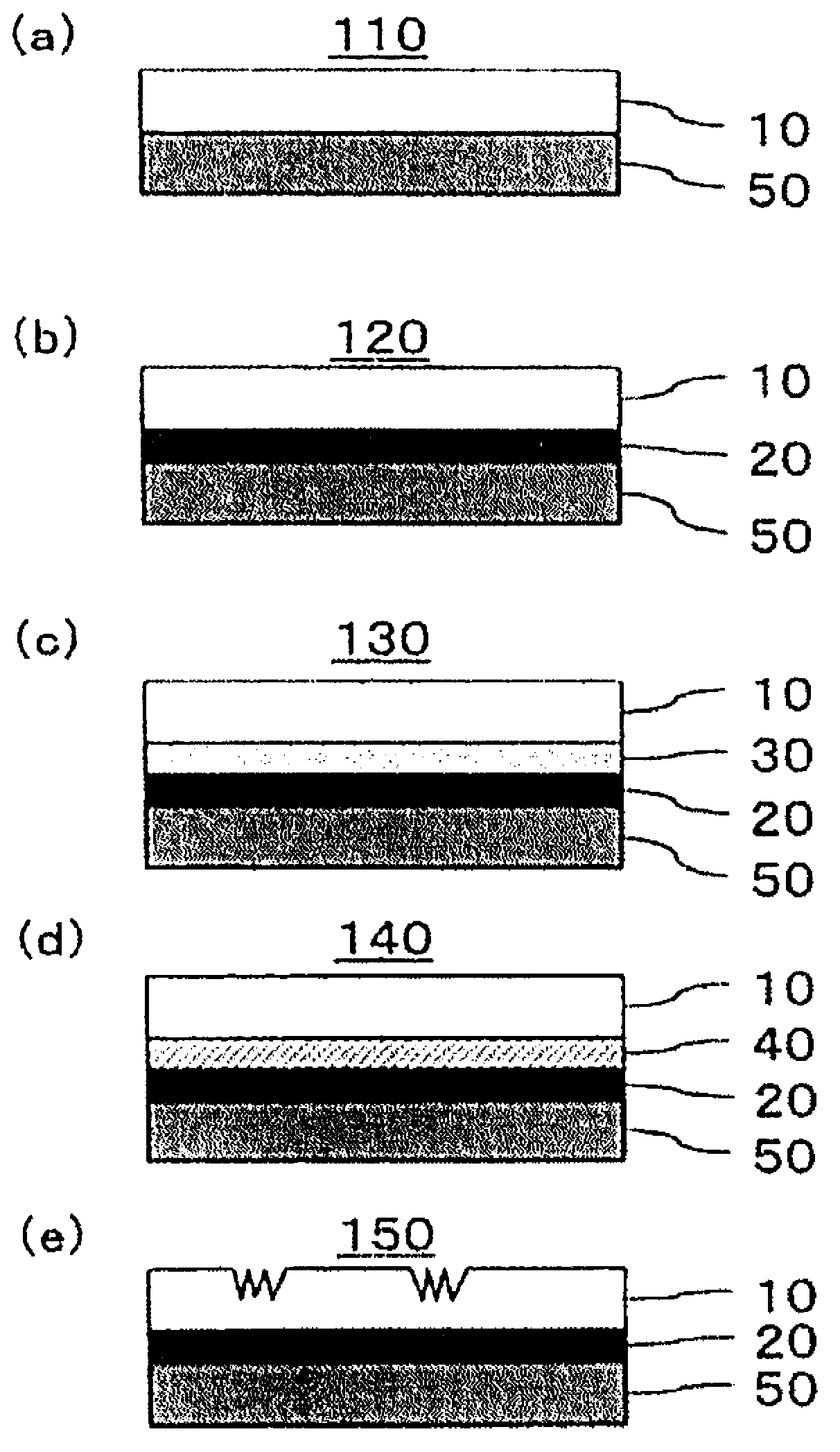

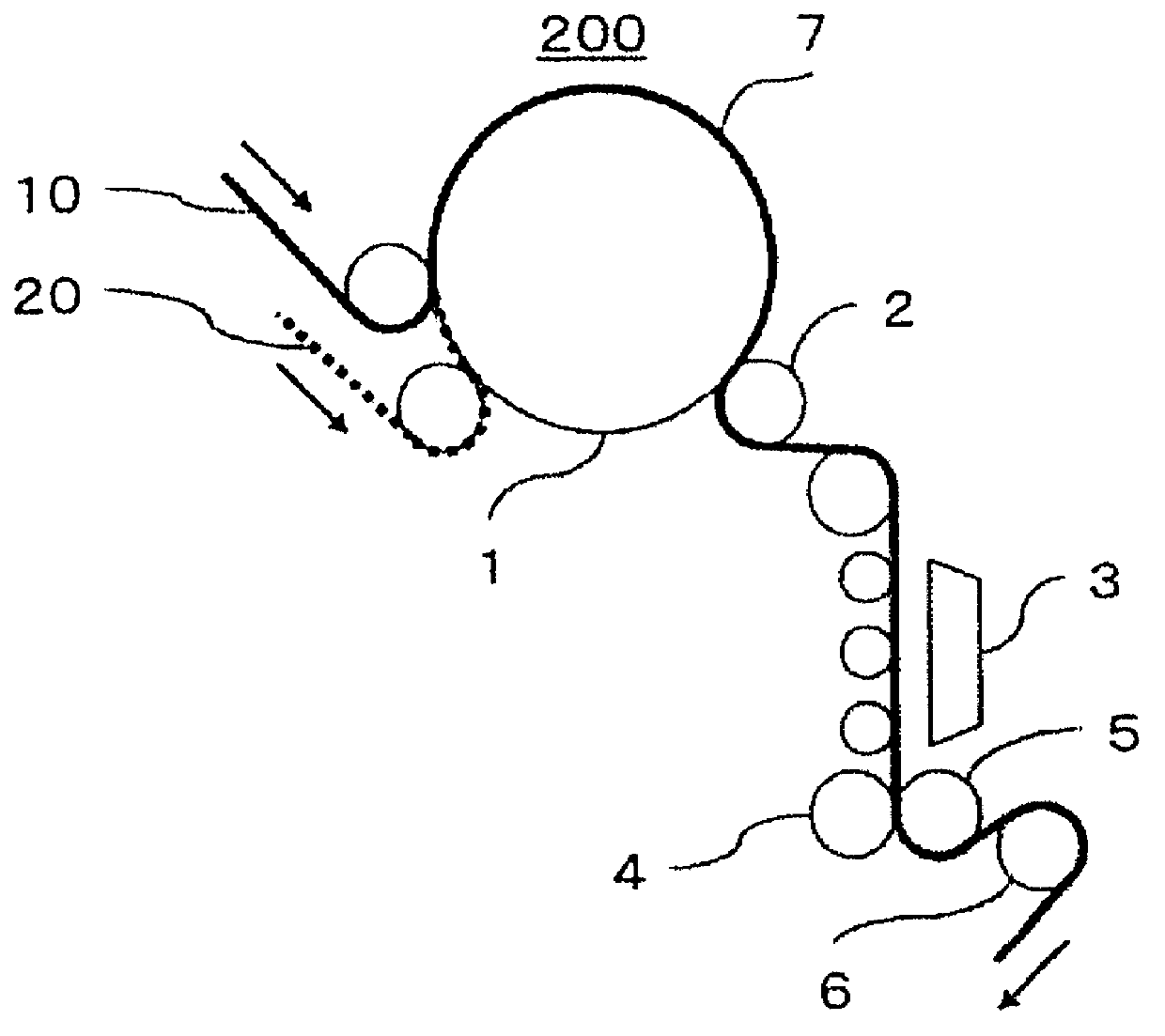

[0229] (a) Production of resin sheet and resin sheet-coated metal laminate

[0230] 1) Raw material mixing and extrusion film making of layer A

[0231] Using isosorbide and 1,4-cyclohexanedimethanol as dihydroxy compounds, a polycarbonate copolymer was obtained by melt polymerization (structural unit derived from isosorbide: derived from 1,4-cyclohexanedimethanol The structural unit=70:30 (mol%)). The obtained polycarbonate copolymer had a glass transition temperature of 120° C. and a reduced viscosity of 0.56 dl / g.

[0232] 4% by weight of the product name "Tinuvin 1577FF" manufactured by BASF Co., Ltd. as an ultraviolet absorber was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com