Vanadium-nitrogen codoped TiO2/attapulgite photocatalysis composite material and preparation thereof

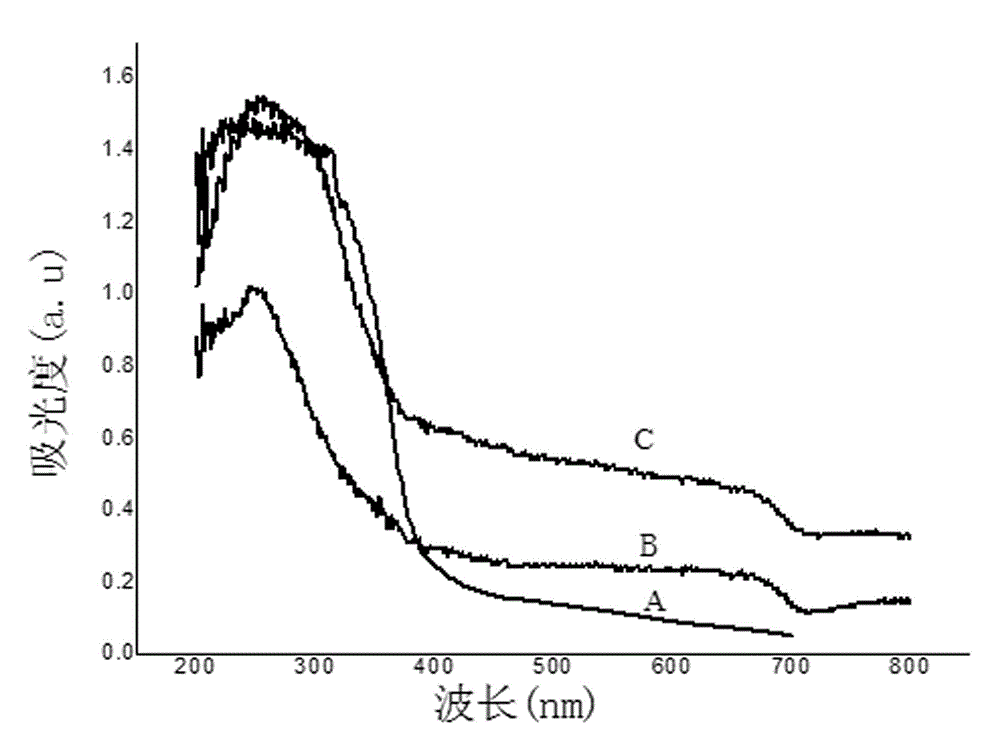

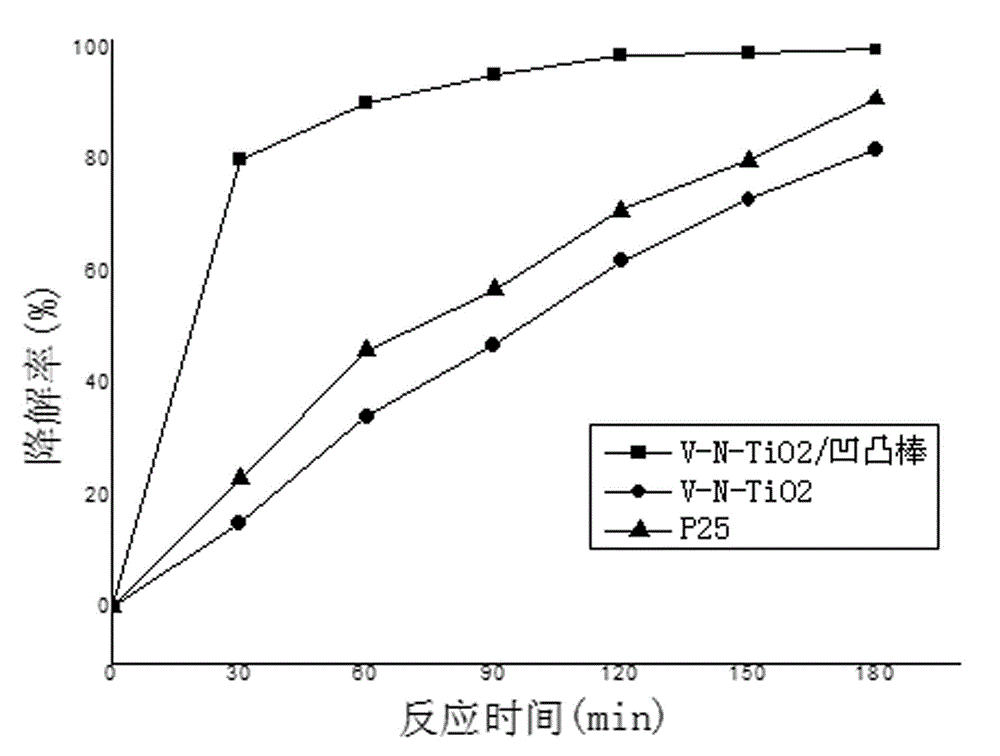

A composite material and attapulgite technology, applied in the field of photocatalytic materials, can solve the problems of narrow spectral response range, difficult separation and recovery, and insufficient degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

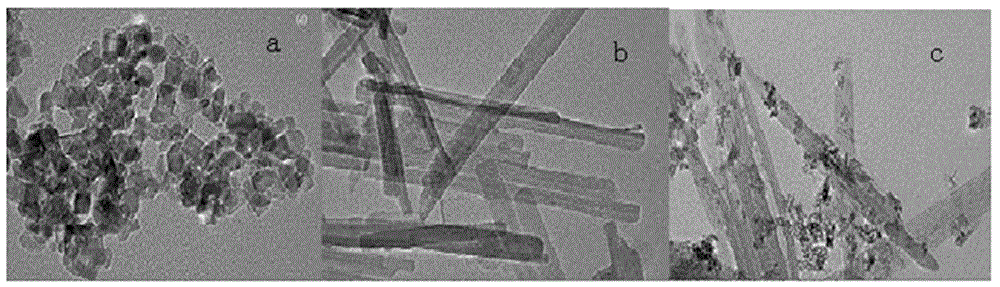

Image

Examples

Embodiment 1

[0033] Purification of attapulgite: fully dissolve 1.5g of sodium pyrophosphate in 605ml of deionized water, heat to 30°C; add 30g of attapulgite original soil under stirring, let stand, extract the suspension; add 2mol / L HCL 100mL, heat Reflux at 80°C for 4 hours, wash until neutral; dry, grind, and pass through a 100-mesh sieve to obtain the purified attapulgite.

[0034] Vanadium-nitrogen co-doped TiO 2 / Preparation of attapulgite photocatalytic composite material: Dissolve 0.0043 g of ammonium metavanadate in the mixed phase of butyl titanate, ethanol, and diethanolamine (butyl titanate 9 mL, ethanol 9.5 mL, diethanolamine 0.5 mL), Under ice-water bath and strong stirring, add the above system into the mixture of acetic acid and deionized water (127 mL of deionized water, 8.5 mL of acetic acid), and continue to stir to form a sol-gel solution; then add the above-mentioned purified Attapulgite 4.4g, continuously stirred for 40min, aged for 12h; then dried in a drying oven...

Embodiment 2

[0037] The purification of attapulgite: with embodiment 1.

[0038] Vanadium-nitrogen co-doped TiO 2 / Attapulgite photocatalytic composite material preparation: Dissolve 0.016g of ammonium metavanadate in the mixed phase of butyl titanate, ethanol and diethanolamine (butyl titanate 5 mL, ethanol 17 mL, diethanolamine 1.1 mL), Under ice-water bath and strong stirring, add to the mixture of acetic acid and deionized water (165 mL of deionized water, 33 mL of acetic acid), and continue to stir to form a sol-gel solution; add 7.2 g of purified attapulgite, Stirring was continued for 70 minutes to obtain a white sol, which was aged for 18 hours; dried in a drying oven at a temperature of 100°C, ground, placed in a muffle furnace, and calcined at 400°C for 2 hours; the calcined powder was ground again, 100 Mesh sieve to prepare vanadium-nitrogen co-doped TiO 2 / Attapulgite Photocatalytic Composite Materials.

[0039] In composite materials, vanadium-nitrogen co-doped TiO 2 The...

Embodiment 3

[0041] The purification of attapulgite: with embodiment 1.

[0042] Vanadium-nitrogen co-doped TiO 2 / Attapulgite photocatalytic composite material preparation: Dissolve 0.0062g ammonium metavanadate in the mixed phase of butyl titanate, ethanol and diethanolamine (butyl titanate 5mL, ethanol 12.1mL, diethanolamine 0.2 mL), in Under ice water bath and strong stirring, add to the mixture of acetic acid and deionized water (deionized water 90mL, acetic acid 5mL), continue to stir to form a sol-gel solution; add 9.58g of purified attapulgite, and continue to stir for 60min , to obtain a white sol, aged for 16 hours; dried in a drying oven at a temperature of 90 ° C, ground, placed in a muffle furnace, and calcined at 450 ° C for 2.5 h; the calcined powder was ground again, and 100 mesh sieve , to prepare vanadium-nitrogen co-doped TiO 2 / Attapulgite Photocatalytic Composite Materials.

[0043] In composite materials, vanadium-nitrogen co-doped TiO 2 The mass ratio of photoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com