Composite modified polyformaldehyde material for preparing water supply pipe insert

A polyoxymethylene material and composite modification technology, applied in the field of engineering plastics, can solve the problem of low tensile strength, tensile coefficient, deflection coefficient, thermal deformation temperature, linear thermal expansion coefficient, sol temperature, and tensile coefficient. , consumption of copper resources and other issues, to achieve the effect of a large temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the rigidity enhancer is 700 mesh light CaCO 3 , the first processing aid is PE wax, the second processing aid is calcium stearate, the coupling agent is trioleoyl isopropyl titanate, the dispersant is paraffin, the impact resistance agent is MBS resin, and the anti-aging agent is Benzophenone anti-aging agent.

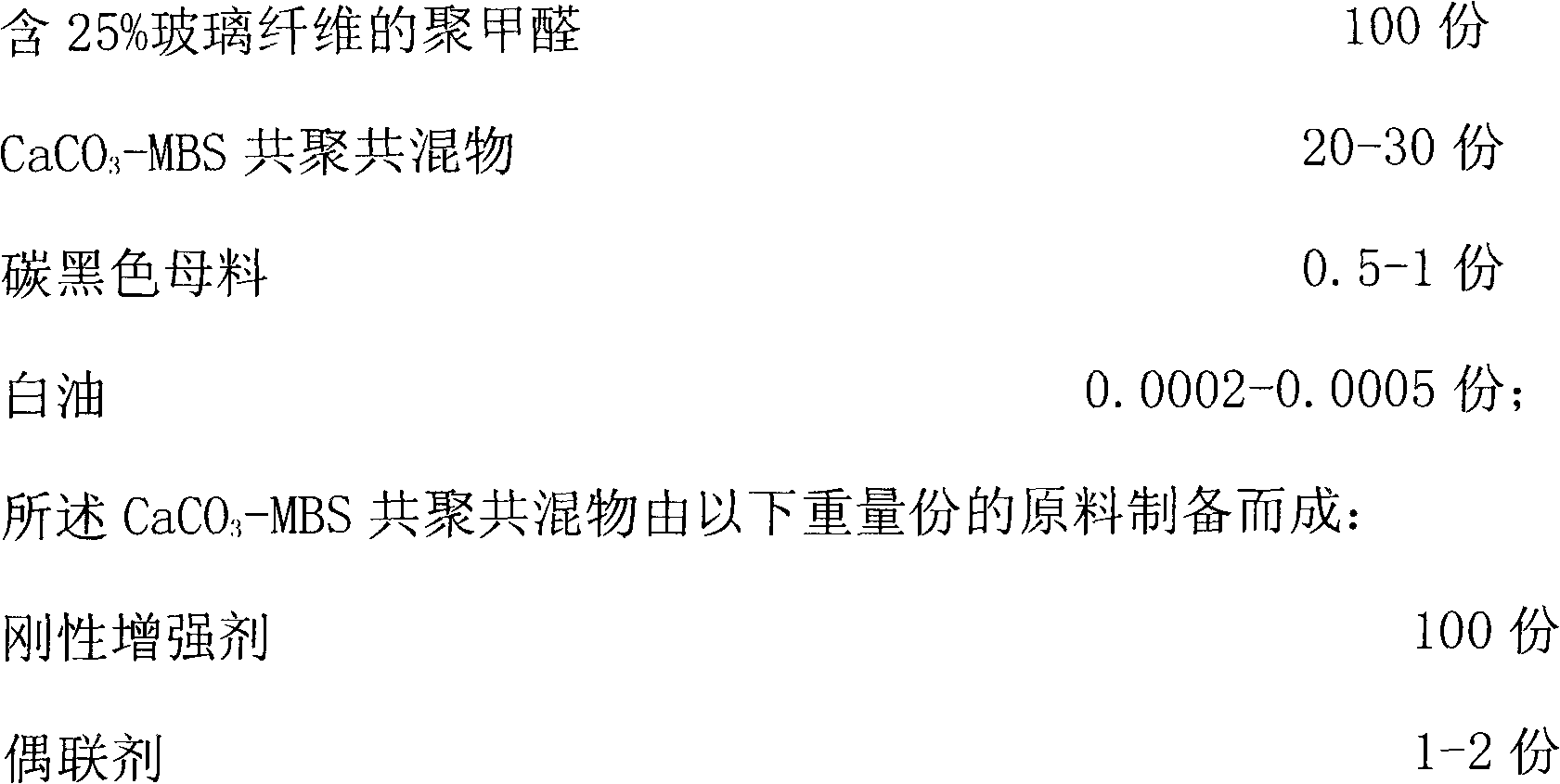

[0023] A composite modified polyoxymethylene material for preparing the inlays of water supply pipe fittings is prepared from the following raw materials in parts by weight:

[0024]

[0025] the CaCO 3 -MBS copolymerization blend is prepared from the following raw materials by weight:

[0026]

Embodiment 2

[0028] In this embodiment, the rigidity enhancer is 700 mesh light CaCO 3 , the first processing aid is PE wax, the second processing aid is calcium stearate, the coupling agent is trioleoyl isopropyl titanate, the dispersant is paraffin, the impact resistance agent is MBS resin, and the anti-aging agent is Benzophenone anti-aging agent.

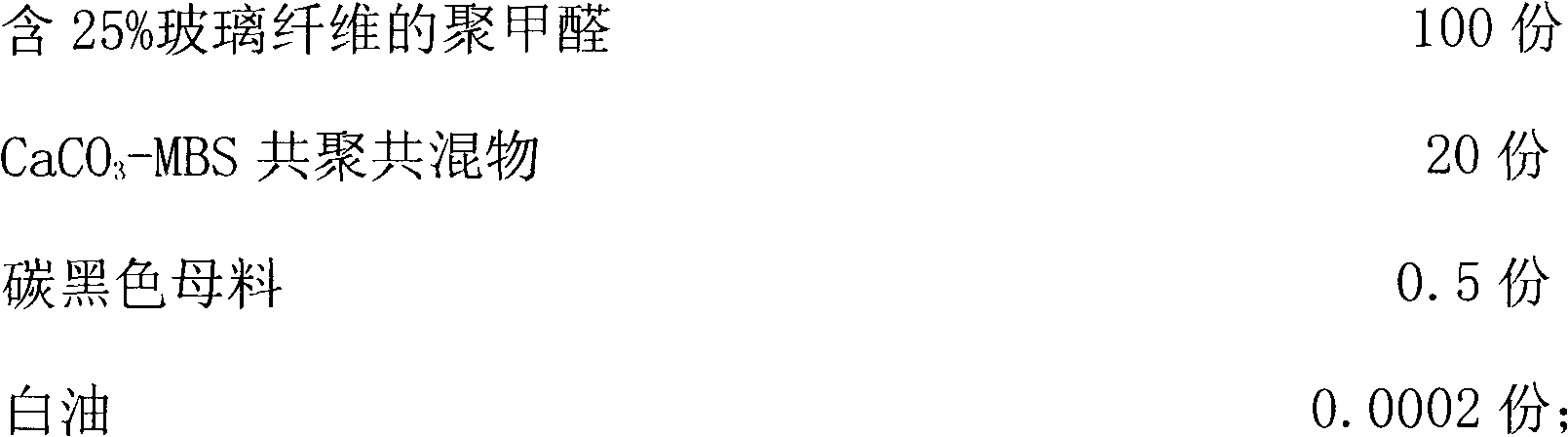

[0029] A composite modified polyoxymethylene material for preparing the inlays of water supply pipe fittings is prepared from the following raw materials in parts by weight:

[0030]

[0031]

[0032] the CaCO 3 -MBS copolymerization blend is prepared from the following raw materials by weight:

[0033]

[0034] The preparation method of the invention is as follows: firstly, the polyoxymethylene containing 25% glass fiber, the CaCO3-MBS copolymer blend and the carbon black masterbatch are dried and then added to a mixer for stirring and mixing, and then white oil is added to the mixer to stir evenly , and then enter the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com