Composite modified polycarbonate material for water supply pipe insert and preparation method thereof

A technology of composite modification and polycarbonate, which is applied in the field of engineering plastics, can solve problems such as low yield, large difference in thermal deformation rate between water supply pipe fittings and polypropylene pipe fittings, and threats to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

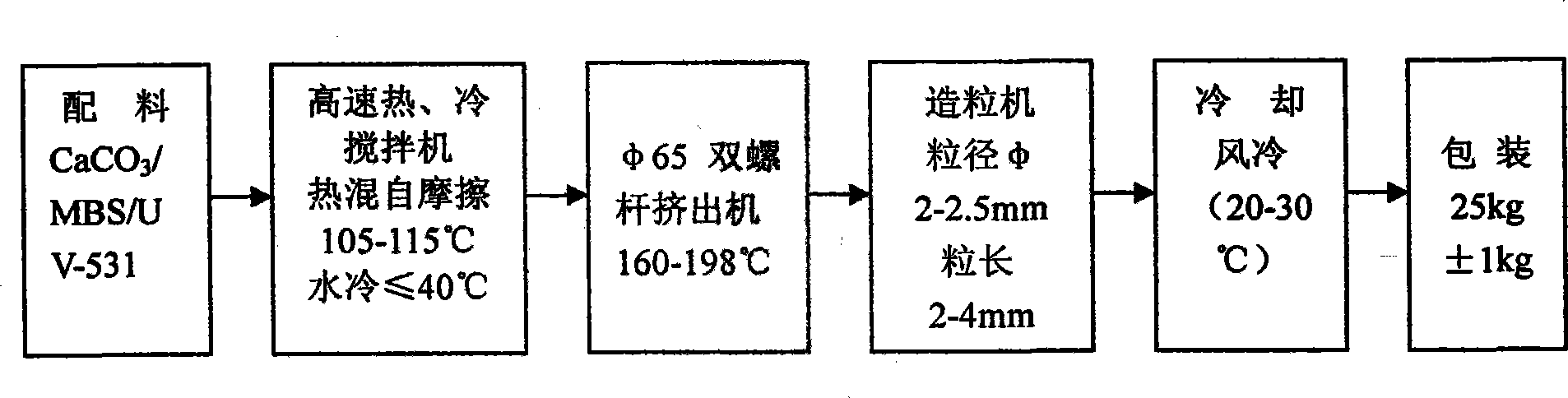

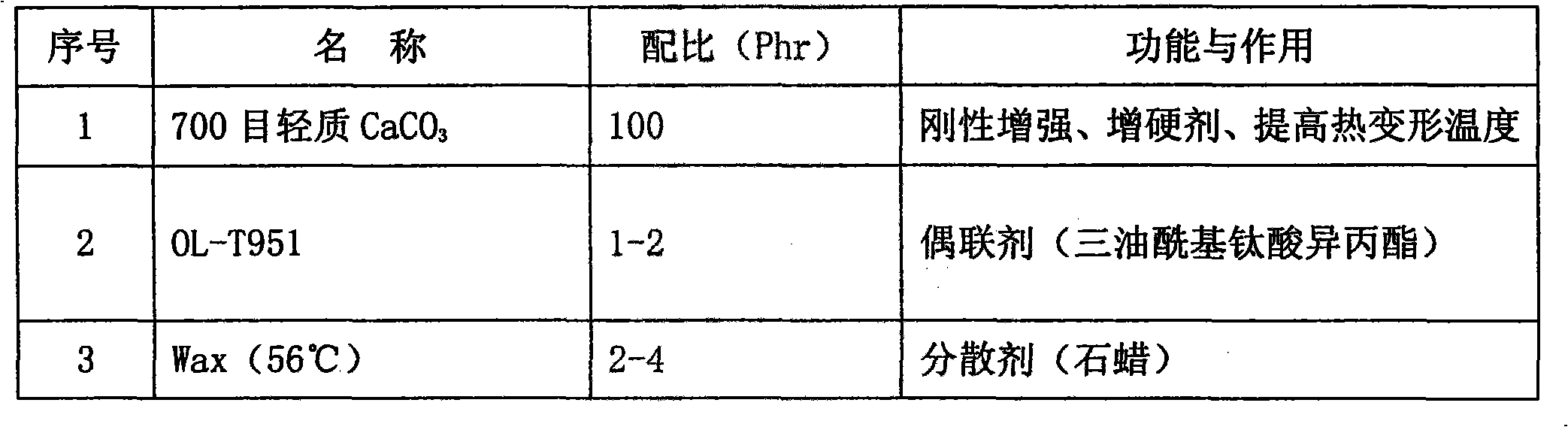

[0030] Embodiment 1: A composite modified polycarbonate material used for water supply pipe fitting inserts, said composite modified polycarbonate material used for water supply pipe fitting inserts consists of the following raw materials in parts by weight: containing 30 100 parts of PC of % glass fiber, 20 parts of CaCO3 / MBS / UV-531 copolymer blend, 0.5 part of carbon black masterbatch and 0.0002 part of white oil. The CaCO3 / MBS / UV-531 copolymer blend is composed of the following raw materials in parts by weight: 100 parts of 700 mesh light CaCO3, 1 part of isopropyl trioleoyl titanate, 2 parts of paraffin, methyl methacrylate- 10 parts of butadiene-styrene copolymer, 0.5 part of anti-aging agent, 1 part of processing lubricant and 1 part of calcium stearate.

Embodiment 2

[0031] Embodiment 2: A composite modified polycarbonate material used for water supply pipe fitting inserts, the composite modified polycarbonate material used for water supply pipe fitting inserts is composed of the following raw materials in parts by weight: containing 30 100 parts of PC of % glass fiber, 30 parts of CaCO3 / MBS / UV-531 copolymer blend, 1 part of carbon black masterbatch and 0.0005 parts of white oil. The CaCO3 / MBS / UV-531 copolymer blend is composed of the following raw materials in parts by weight: 100 parts of 700 mesh light CaCO3, 2 parts of coupling agent, 4 parts of dispersant, 15 parts of anti-impact agent, 1 part of anti-aging agent part, 3 parts of processing lubricant and 2 parts of calcium stearate, the coupling agent is isopropyl trioleoyl titanate, the dispersant is paraffin, and the anti-shock agent is methyl methacrylate-butylene Diene-styrene copolymer.

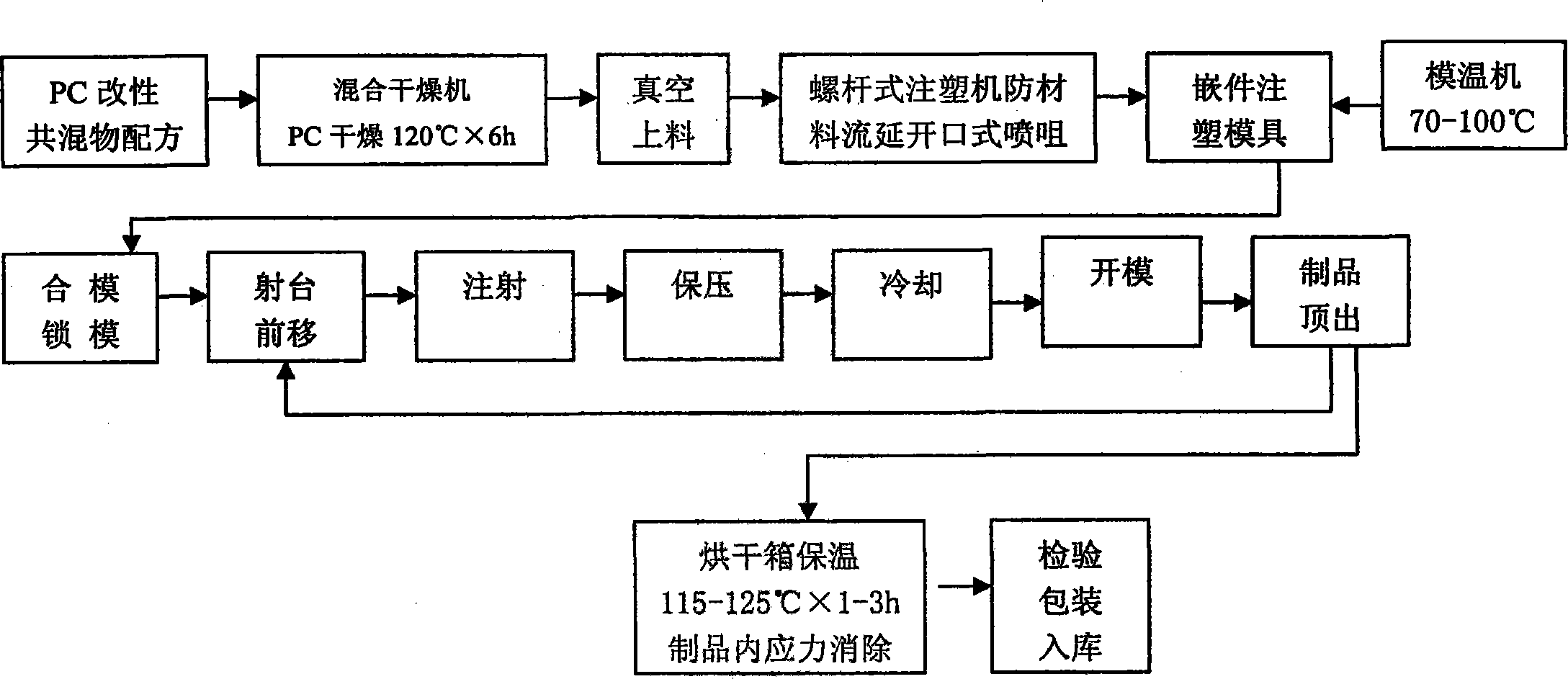

[0032] like figure 1 Shown, a kind of preparation method of the composite modified polycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com