Quantitative detection method of aroma components in yellow serofluid

A technology for quantitative detection of aroma components, which is applied in the field of detection analysis and quantitative detection of aroma components in yellow pulp water, can solve the problems of cumbersome operation, difficult quantification, inaccuracy, etc., and achieve the goals of preventing quantitative distortion, protecting the safety of use, and overcoming discrimination effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

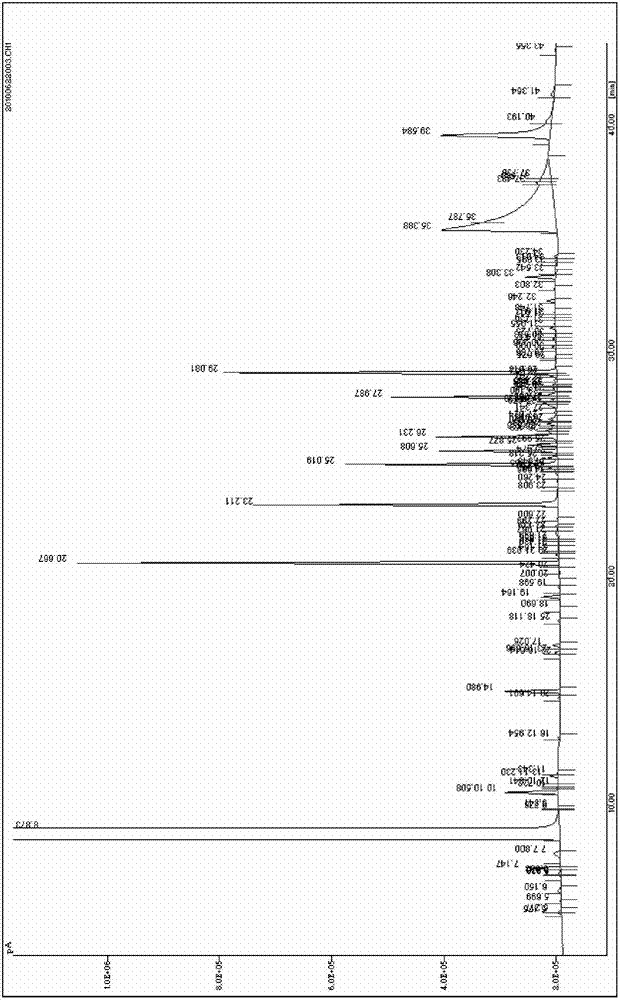

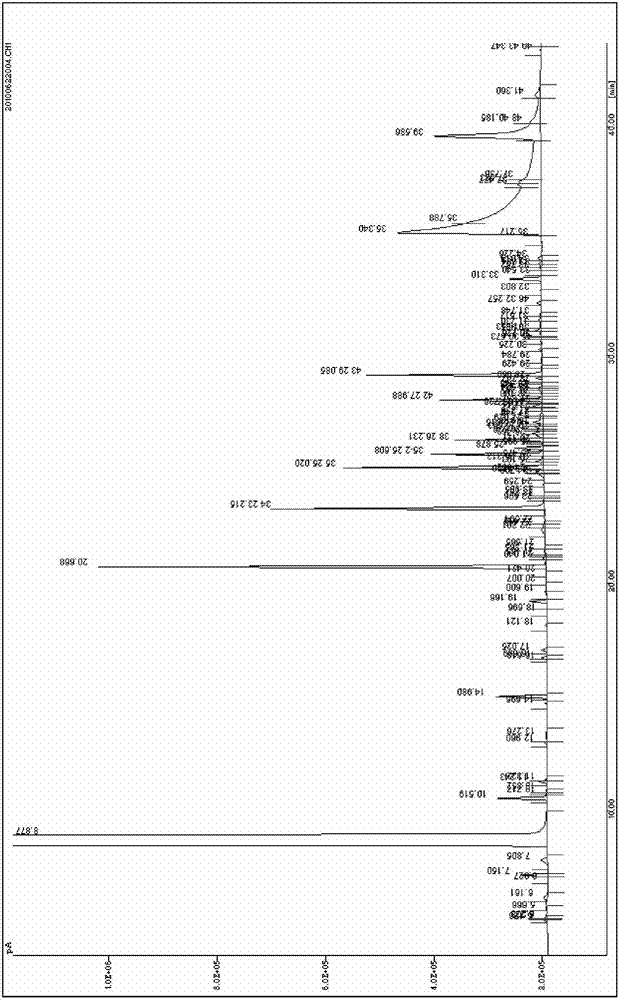

Embodiment 1

[0031] 1. Pretreatment: Use a 25ml pot-bellied straw to absorb 25ml of yellow pulp water, put it in a 50ml volumetric flask, and then add ethanol solution with a volume concentration of 96% to make up to volume. Fully mix the yellow pulp water and alcohol to obtain a mixed solution, and make it sealed and fully precipitated for 0.5h. The mixed solution is subjected to airtight coarse filtration with qualitative filter paper to obtain a relatively clear crude filtrate, and the crude filtrate is filtered with a 0.45 μm microporous membrane to obtain a pretreatment solution.

[0032] 2. Detection: draw 10ml of pretreatment solution, then add 0.1ml of mixed internal standard, mix well and analyze by gas chromatography. The detection conditions of gas chromatography detection are:

[0033] Chromatographic column: CP-WAX57CB capillary column 50m×0.25mm×0.20μm from American Varian Chrompack Company;

[0034] Column temperature: second-stage temperature program, the initial temperat...

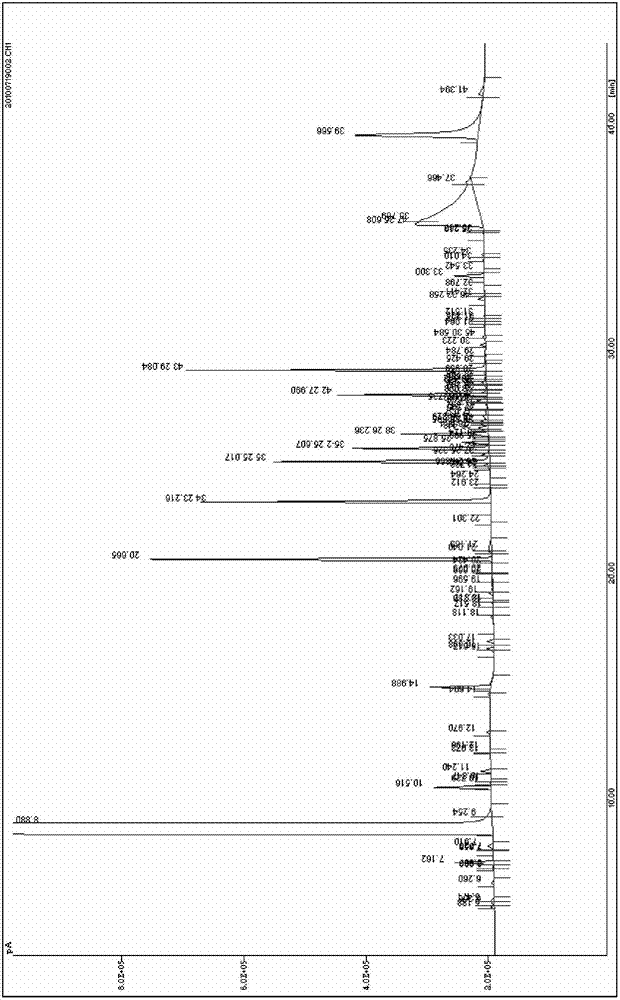

Embodiment 2

[0047] 1. Pretreatment: Use a 25ml pot-bellied straw to draw 25ml of yellow pulp water, put it in a 50ml volumetric flask, then add ethanol solution with a volume concentration of 96% to constant volume, mix evenly to obtain a mixed solution, seal the mixed solution and fully precipitate it for 0.5h , and then centrifuged, the centrifugal speed is 10000r / min, the centrifugation time is 10min, and the supernatant is collected. The supernatant was filtered with a 0.45 μm microporous membrane to obtain a pretreatment solution.

[0048] 2, detection: detection method is the same as embodiment 1.

[0049] The aroma components and content of the yellow jelly water are shown in Table 2. Because the detection liquid is the yellow jelly water after volume dilution of 1:1, the content of the aroma components in the actual yellow jelly water is twice the test result. Using this pretreatment method combined with centrifugation and microfiltration, the gas chromatogram of Huangjiangshui N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com