Ferrite/polypyrrole (PPy) magnetic nano-photocatalyst and preparation method thereof

A magnetic nanometer and ferrite technology, applied in the field of material chemistry, can solve the problems of recovery and recycling, and achieve convenient recovery and recycling, high-efficiency adsorption performance, good application prospects and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

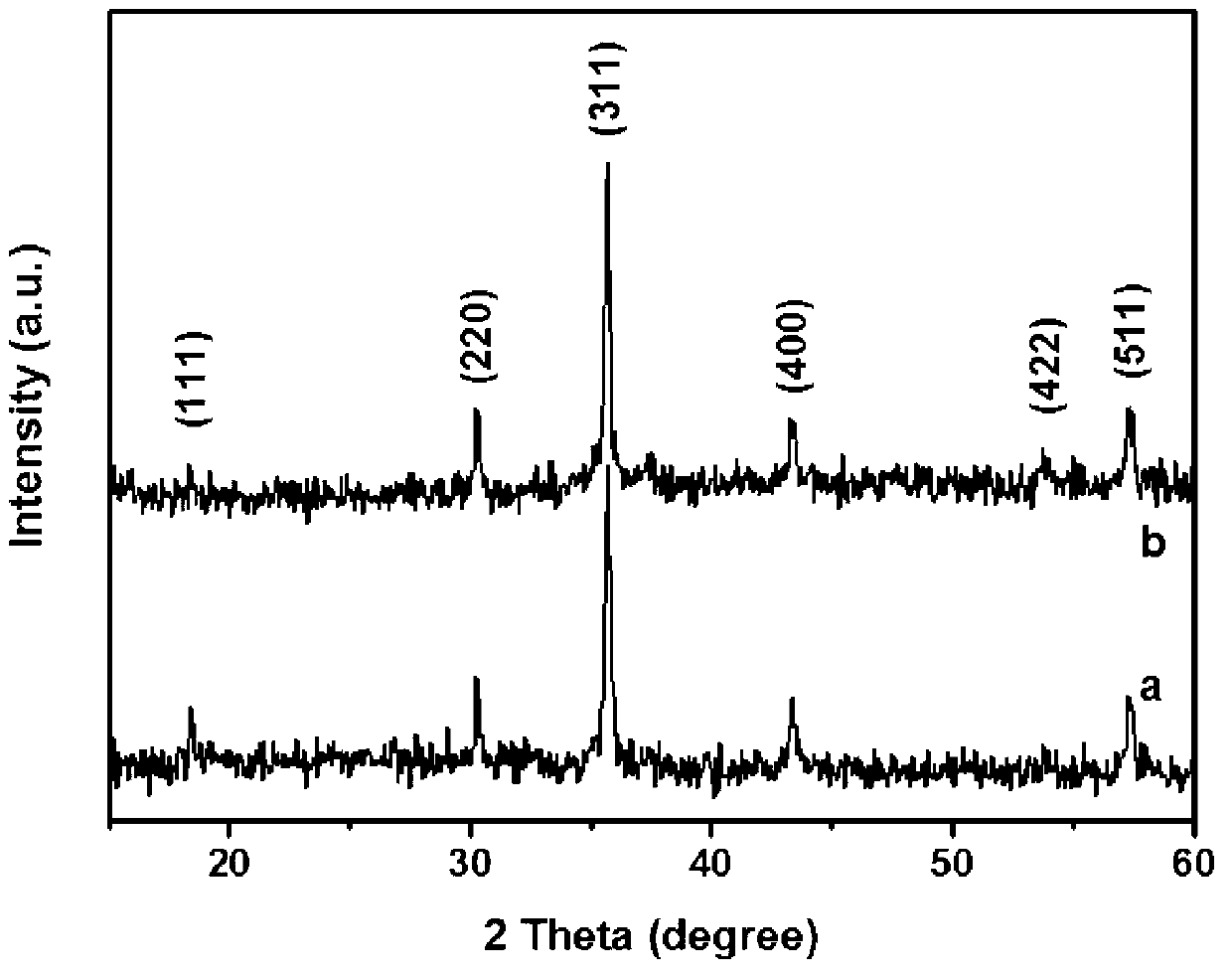

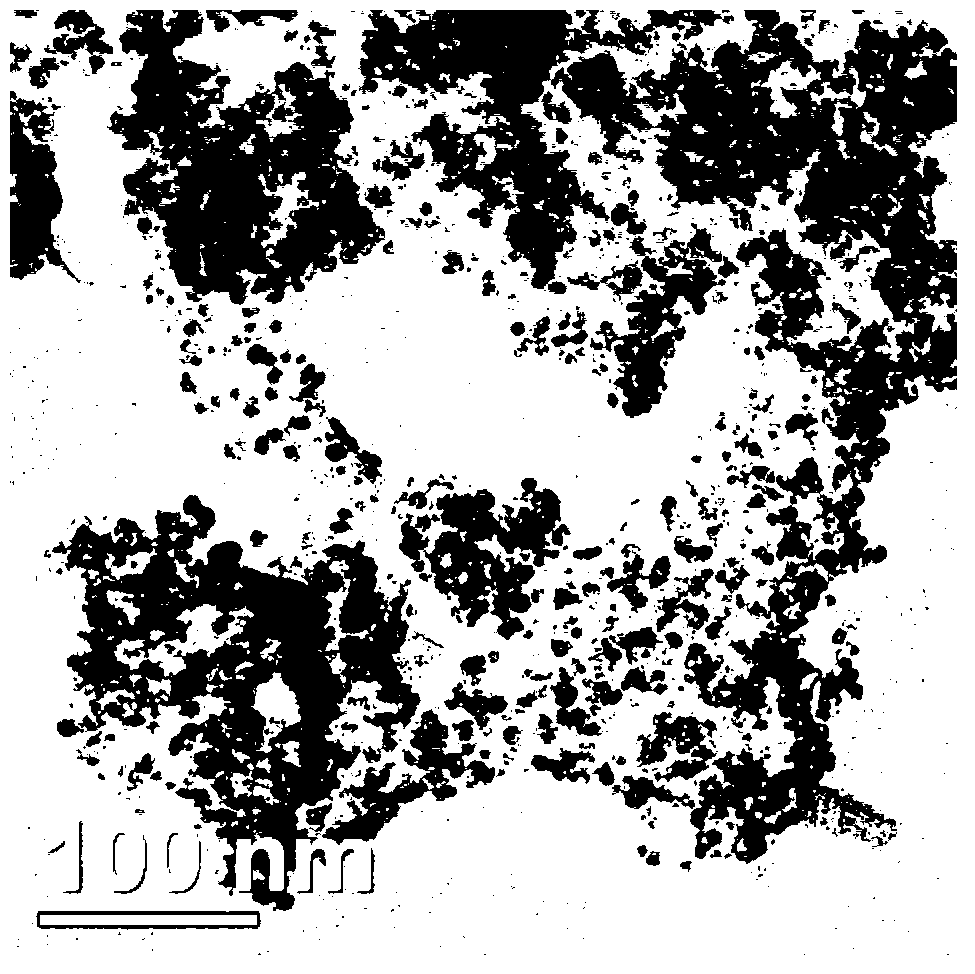

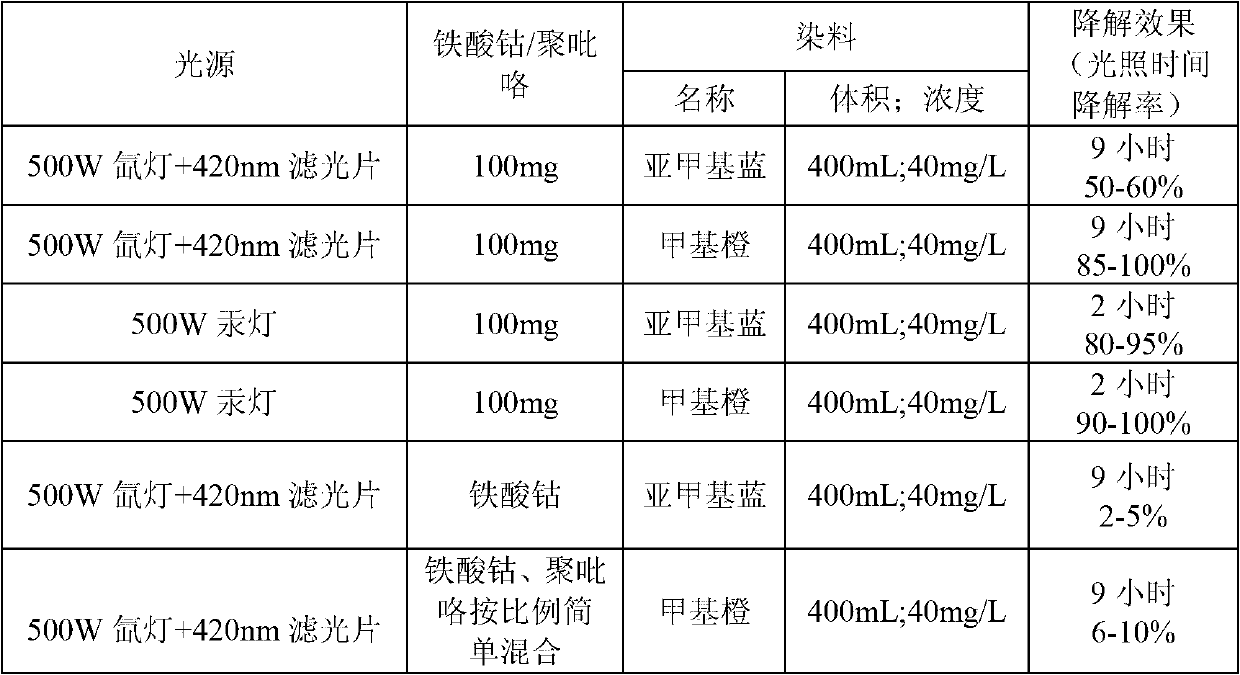

[0026] Embodiment 1: the preparation method of cobalt ferrite / polypyrrole magnetic nano-catalyst, comprising the following steps:

[0027] The first step is to stir and dissolve ferric nitrate and cobalt nitrate with a molar ratio of 2:1 in ethanol;

[0028] In the second step, the mol ratio with the cobalt nitrate added in the step 1 is that 20 sodium hydroxide is added to the solution obtained in the first step, and is fully stirred;

[0029] In the third step, the reaction system of the second step was transferred to a hydrothermal kettle and heated to 180 ° C for 20 h;

[0030] The fourth step, the product of the third step is centrifuged, washed with deionized water, and dried to obtain nano-cobalt ferrite;

[0031] The 5th step, the nano cobalt ferrite and ammonium persulfate obtained in the 4th step are dispersed in 0.5mol / L hydrogen chloride solution;

[0032] The 6th step, at 0~4 ℃ of temperature, the pyrrole that is 1:1 with the mol ratio of the ammonium persulfate...

Embodiment 2

[0041] Embodiment 2: the preparation method of nickel ferrite / polypyrrole magnetic nanocatalyst, comprises the following steps:

[0042] The first step, the ferric nitrate and nickel nitrate that the molar ratio is 2:1 is stirred in ethanol for 30min;

[0043] In the second step, the mol ratio with the nickel nitrate added in the step one is that 40 sodium hydroxide is added to the solution obtained in the first step, and is fully stirred;

[0044] In the third step, the reaction system in the second step was transferred to a hydrothermal kettle and heated to 120 ° C for 12 h;

[0045]In the fourth step, the product of the third step is centrifuged, washed with deionized water, and dried to obtain nano-nickel ferrite;

[0046] The 5th step, the nano nickel ferrite and the ammonium persulfate of the 4th step gained are dispersed in the 1mol / L hydrogen chloride solution;

[0047] In the sixth step, at a temperature of 0 to 4°C, pyrrole with a molar ratio of 1:1 to the ammonium...

Embodiment 3

[0053] Implementation example 3: the preparation method of copper ferrite / polypyrrole magnetic nano-catalyst comprises the following steps:

[0054] In the first step, ferric nitrate and copper nitrate with a molar ratio of 2:1 were stirred in ethanol for 10 min;

[0055] In the second step, the mol ratio of the copper nitrate added in the step one is that 5 sodium hydroxide is added in the solution obtained in the first step, fully stirred;

[0056] In the third step, transfer the reaction system of the second step to a hydrothermal kettle and raise the temperature to 200°C, and react for 24 hours;

[0057] In the fourth step, the product of the third step is centrifuged, washed with deionized water, and dried to obtain nano-copper ferrite;

[0058] The 5th step, the nano copper ferrite of the 4th step gained and ammonium persulfate are dispersed in the 0.8mol / L hydrogen chloride solution;

[0059] In the sixth step, at a temperature of 0 to 4°C, pyrrole with a molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com