Method for spraying coating and killing coating on surface of oil tank and for jointly preventing corrosion

A surface spraying and coating technology, used in devices for coating liquids on surfaces, paints containing biocides, coatings, etc. Excellent anti-corrosion performance, reducing the effect of microbial corrosion and corrosion under scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

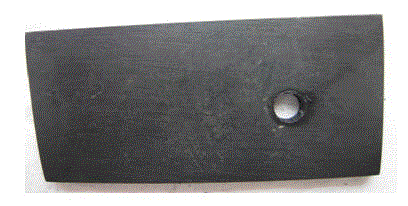

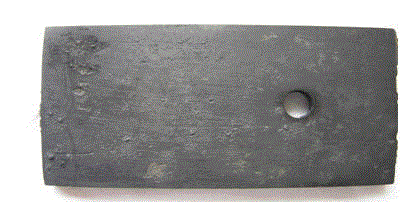

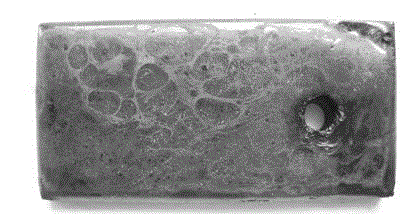

Image

Examples

Embodiment Construction

[0033] The method of the present invention is used to carry out anti-corrosion treatment on the inner wall of the oil tank, and the cathodic protection metal coating formed by aluminum or aluminum and glass flakes is sprayed on the inner surface of the tank to form cathodic protection for the metal of the tank body; the metal anti-corrosion coating is coated with The biocidal and antibacterial coating composed of modified epoxy resin and biocide prevents microbial corrosion caused by the deposition of various bacteria in the bottom of the tank.

[0034] The specific method includes the following steps:

[0035] 1. Metal spraying process

[0036] (1) cleaning

[0037] Use water with temperature ≥ 70°C, pressure ≥ 12MPa and detergent to clean the oil in the tank.

[0038] (2) Corrosion repair pit

[0039] The existing corrosion pits on the tank wall and tank bottom, especially the larger ones, are repaired by surfacing welding and ground to a flat surface.

[0040] (3) Sandb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com