Preparation method of cumene

A technology of cumene and dimethyl benzyl alcohol, applied in the field of hydrogenolysis α, can solve the problems of high price, low activity, environmental pollution, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

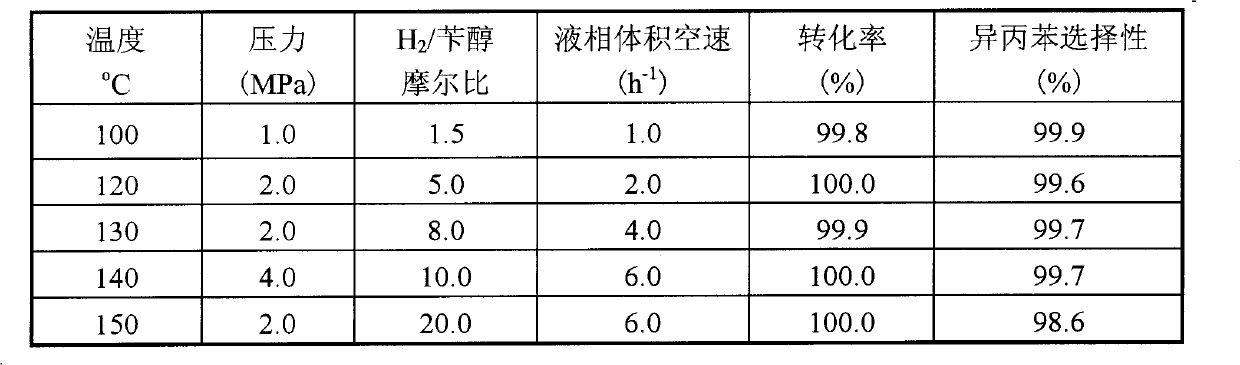

Embodiment 1

[0016] Add 10.0g of pseudoboehmite powder to 100.0g of water, add 2.0g of concentrated nitric acid, and peptize at 70°C for 24 hours to obtain alumina sol. Get 23.4g basic nickel carbonate and 100.0g ammonia water and add 100.0g water to prepare nickel ammonia complex solution. Add the nickel ammonia complex solution to the aluminum sol, add sodium carbonate to adjust the pH of the solution to 9 and age for 12 hours, then heat and decompose at 70-120°C for 12 hours, wash, filter and dry to obtain the catalyst precursor. 5.0gMg(NO 3 ) 2 ·6H 2 The solution made of O and 20.0g water is impregnated on the precursor, and the weight percentage is 30%NiO-5%MgO-65%Al after roasting. 2 o 3 catalyst. After the catalyst is reduced by hydrogen at 450°C, the content of α,α-dimethylbenzyl alcohol is 25.0%, and the content of cumene is 75.0% as raw materials, and the reaction pressure is 0.1MPa, H 2 / α, the volume ratio of α-dimethylbenzyl alcohol is 400, and the volume space velocity ...

Embodiment 2~10

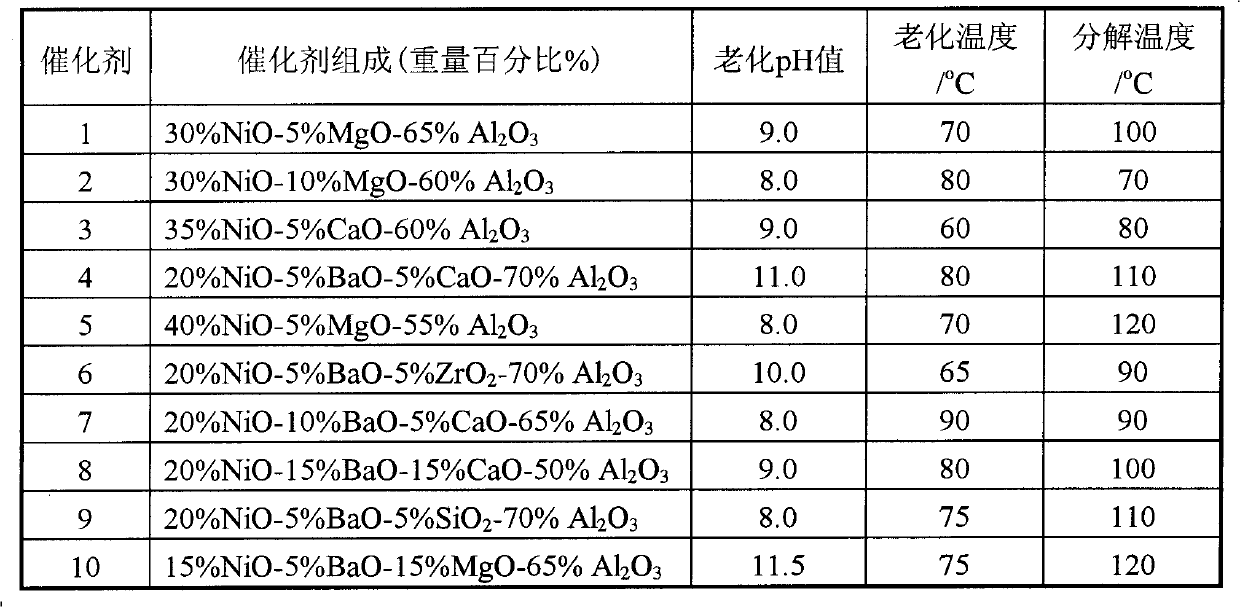

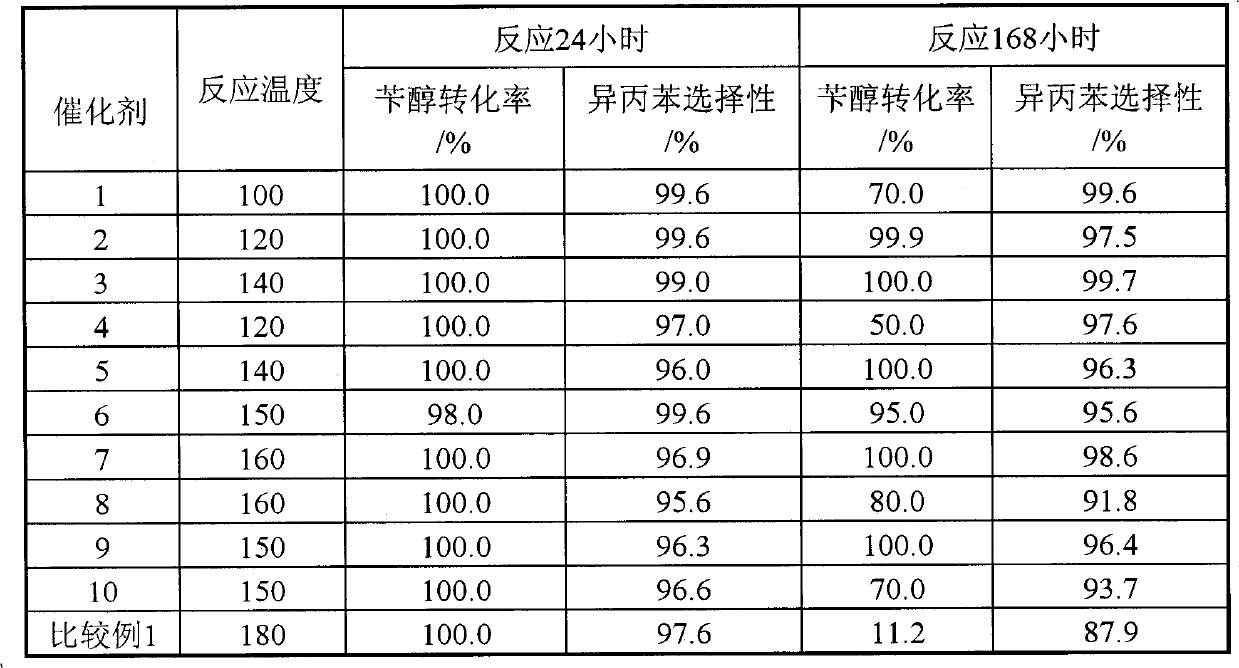

[0018] Catalysts 2 to 10 were prepared according to the steps in Example 1, except that the material composition and preparation conditions were changed. The preparation conditions and material composition of the catalysts were shown in Table 1, and the hydrogenolysis evaluation results were shown in Table 2.

[0019] Table 1 The composition and preparation conditions of each catalyst

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com