Refining method of oteracil potassium

A technique for refining oteracil potassium, which is applied in the field of refining oteracil potassium, can solve the problems of easy decarboxylation, inability to remove impurities, increase of operation steps and production cost, and achieve stable quality, yield and purity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

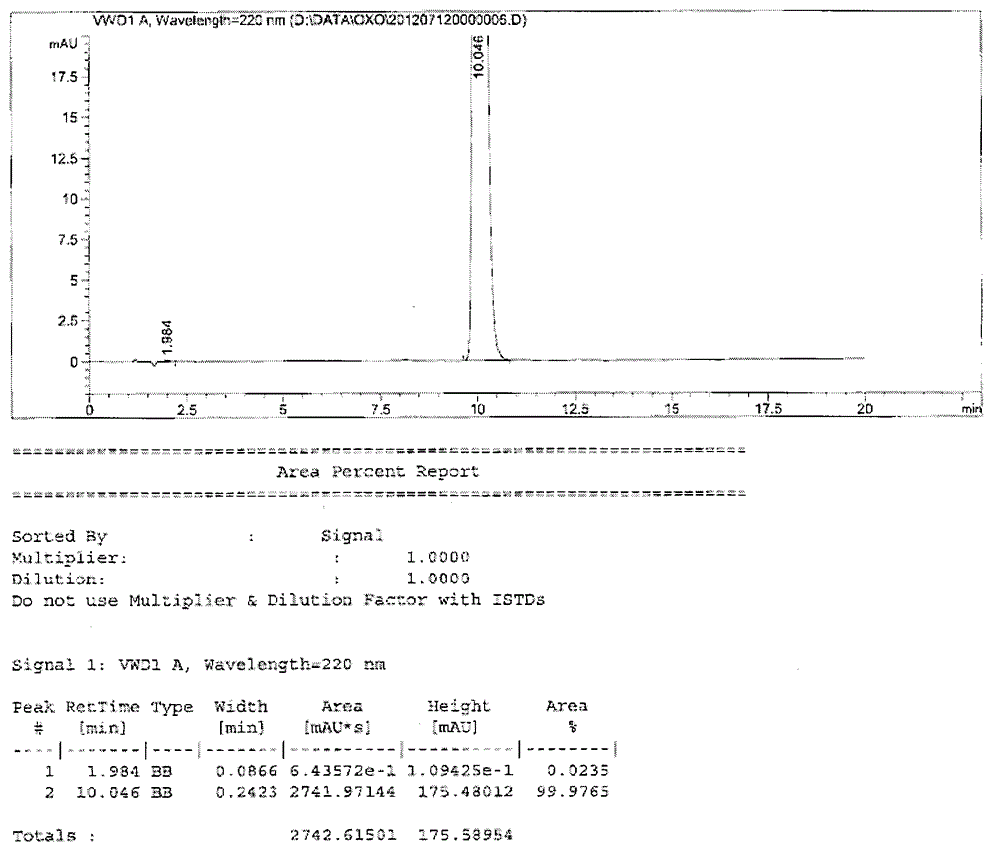

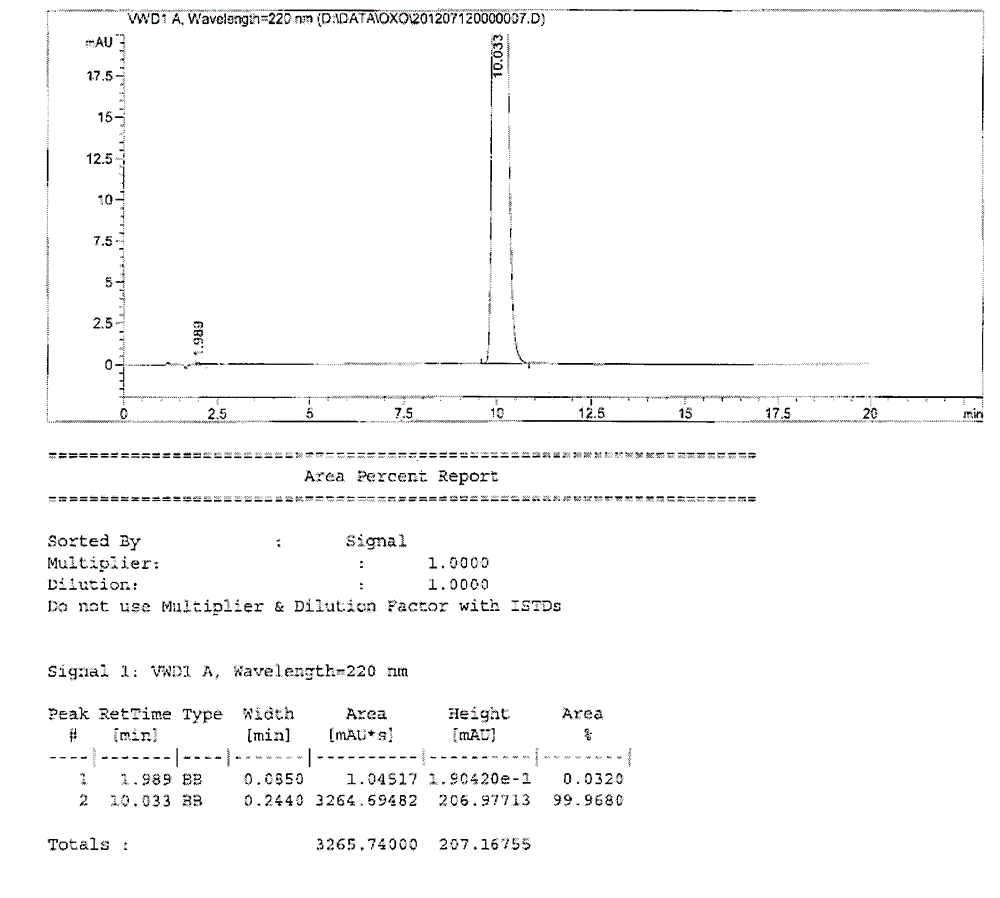

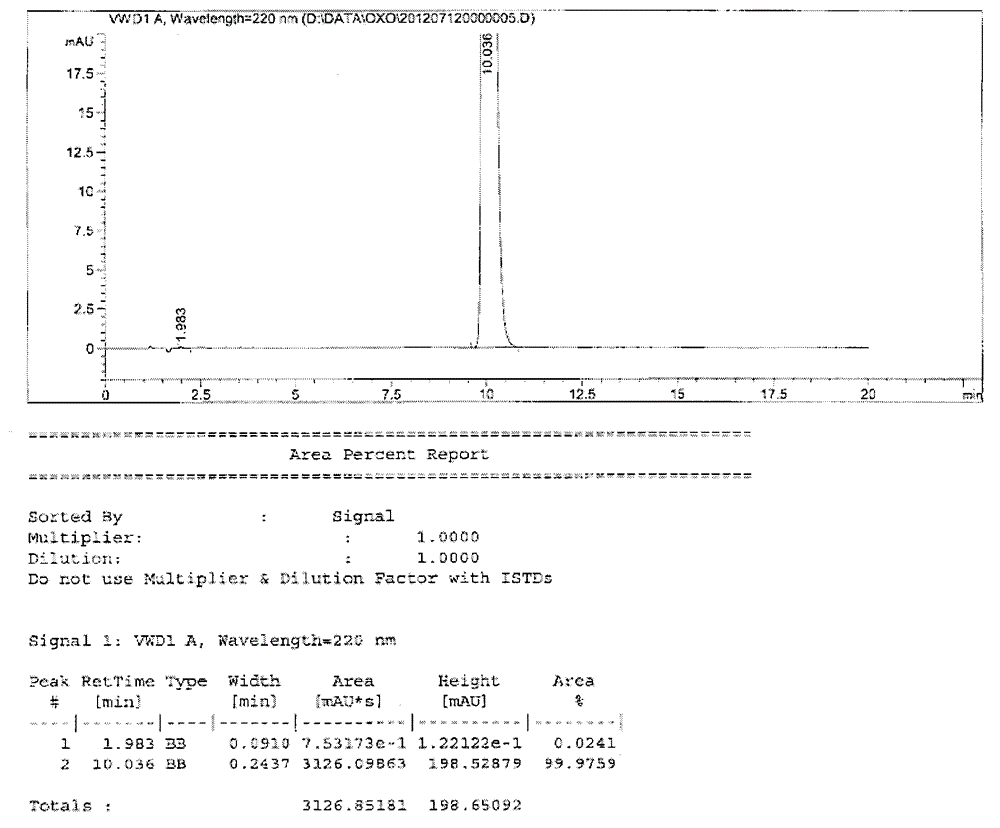

[0029] Adopt HPLC method to measure the purity of oteracil potassium among the present invention, chromatographic condition is as follows: stationary phase: octadecylsilane bonded silica gel; Mobile phase: phosphate buffer saline-methanol (9: 1), wherein phosphate buffer saline The composition of the solution is: potassium dihydrogen phosphate 0.65g, add water to 900mL, add 10% tetrabutylammonium hydroxide 2mL, adjust pH to 3.2 with phosphoric acid;

[0030] Column temperature: 35°C; detection wavelength: 220nm; injection volume: 10μL.

Embodiment 2

[0032] Add 1kg of crude product of oteracil potassium to 7.5L of aqueous solution containing 8% potassium carbonate, heat to 35°C, stir until the solid dissolves, filter, add 5L of ethanol to the filtrate, cool to 5°C, and stand for crystallization for 2 hours, filtered, and the filter cake was vacuum-dried at 60° C. to obtain 943 g of oteracil potassium crystals, with a yield of 94.3%. After HPLC detection, the peak time of 10.0 minutes is oteracil potassium, with a peak area of 99.9765%, and the peak time of 1.98 minutes is impurity 5-AZU, with a peak area of 0.0235%.

Embodiment 3

[0034] Add 1 kg of oteracil potassium crude product to 15 L of aqueous solution containing 1% triethylamine, heat to 50 ° C, stir until the solid dissolves, filter, add 18 L of ethanol and acetone mixed solution to the filtrate, cool to 5 ° C, Stand still for crystallization for 8 hours, filter, and vacuum-dry the filter cake at 60° C. to obtain 912 g of oteracil potassium crystals, with a yield of 91.2%. Through HPLC detection, the peak time of 10.0 minutes is oteracil potassium, with a peak area of 99.9680%, and the peak time of 1.98 minutes is impurity 5-AZU, with a peak area of 0.0320%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com