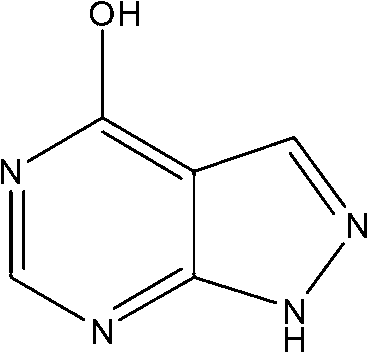

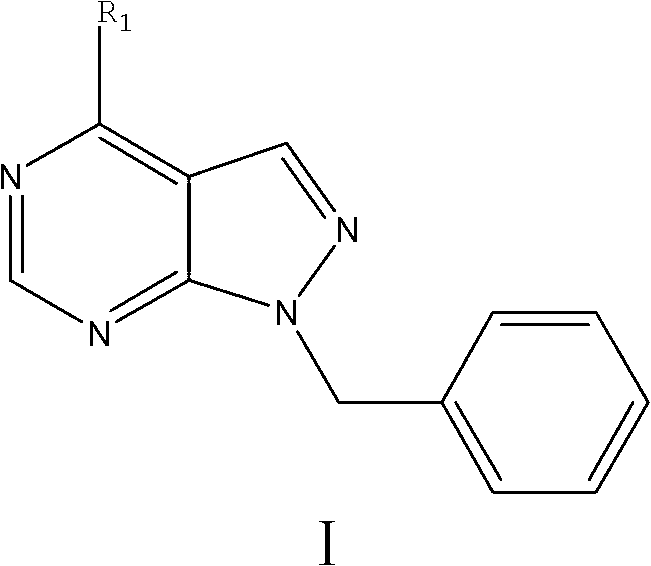

1-N-benzyl allopurinol derivative as well as preparation method and application thereof

A technology of -4-N-2, benzyl, applied in the field of allopurinol derivatives and its preparation, achieving the effects of simple preparation method, inhibition of xanthine oxidase activity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

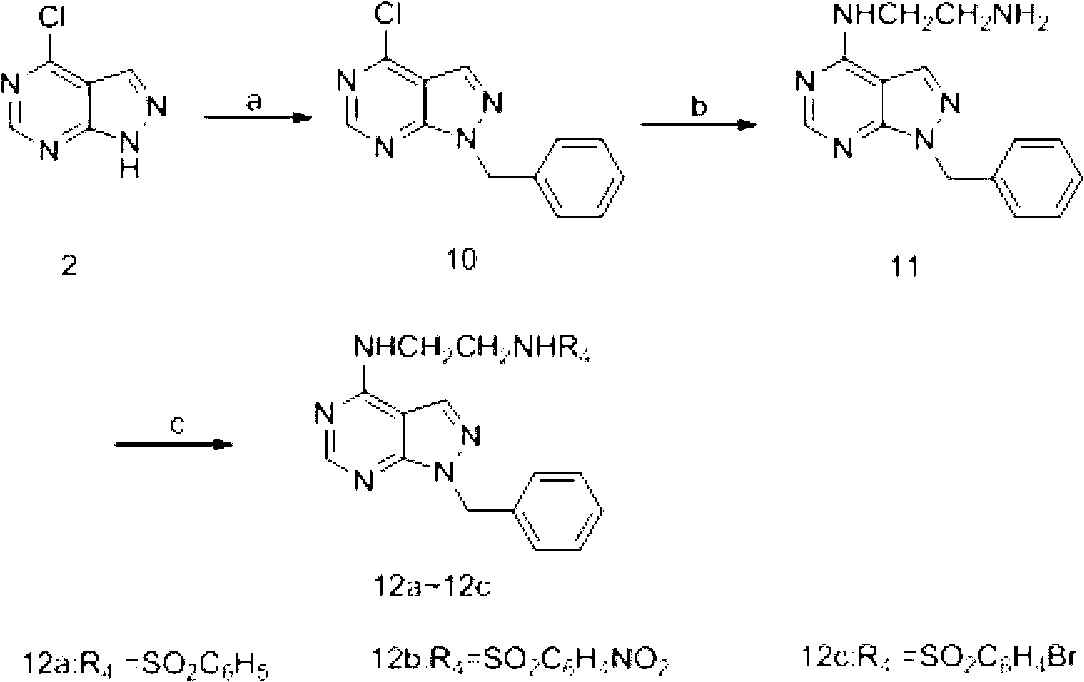

[0038] Example 14 Synthesis of chloro-1-benzyl-1H-pyrazol[3,4-d]pyrimidine (compound 10 for short)

[0039] Compound 2 (0.1g, 0.65mmol) was dissolved in 5mL of dry DMF, the reaction solution was stirred at room temperature for 10min, and a good amount of triethylamine (0.22g, 0.65mmol) was slowly added dropwise with a dropping funnel, and stirring was continued at room temperature 30min. Benzyl bromide (0.11 g, 0.78 mmol) dissolved in 5 mL of dry DMF was slowly added dropwise to the mixture, stirring was continued for 1 h, and then a catalytic amount of KI was added. The reaction solution was detected by TLC until complete reaction was detected, the mixed solution was poured into 15 mL of water, and the pH was adjusted to acidic with dilute hydrochloric acid, then extracted with ethyl acetate (4×20 mL), the organic layer was washed with saturated sodium chloride, anhydrous magnesium sulfate Dry and concentrate. The crude product was subjected to silica gel column chromatogra...

Embodiment 2

[0041] Example 2 Synthesis of N'-(1'-benzyl-1H-pyrazol[3,4-d]pyrimidin-4'-yl-)-1,2-ethylenediamine (compound 11 for short)

[0042] Compound 10 (0.10 g, 0.41 mmol) was dissolved in 10 mL of acetonitrile, and then ethylenediamine (0.025 g, 0.42 mmol) was slowly added to the mixture, stirred at room temperature, and detected by TLC until complete reaction. The reaction solution was concentrated to obtain a yellow oily liquid, and the crude product was subjected to silica gel column chromatography, first passed through the column with dichloromethane:methanol (2:8 drops), and then eluted with methanol to obtain a yellow oily liquid 11.

[0043] 11: yellow oily liquid 1 H NMR (400MHz, DMSO-d 6 )δ:8.61(br,1H,NH),8.25(s,1H,CH),8.03(s,1H,CH),7.19~7.32(m,5H,ArH),5.50(s,2H,CH 2 ),3.59(dd,2H,CH 2 ), 3.13 (dd, J=6.10Hz, J=12.10Hz, 2H, CH2 ),2.88(t,J=6.10Hz,2H,NH 2 ); 13 C NMR (100MHz, DMSO-d 6 )156.47,155.83,152.67,137.33,132.37,128.45,127.40,100.52,49.71,41.26,40.63;IR(KBr,v,cm -...

Embodiment 3

[0044] The synthesis of embodiment 3 compound 12a~12c

[0045] Compound 11 (0.32g, 1.19mmol) and TEA (0.18g, 1.78mmol) were successively added to 10mL of dry DMF under ice-free conditions, stirred for a period of time, and then the benzenesulfonyl chloride dissolved in 2mL of dry DMF (0.25g, 1.79mmol) was slowly added dropwise to the mixture, and stirring was continued under ice bath conditions. The reaction solution was detected by TLC and poured into 15 mL of water, and extracted with ethyl acetate (3×15 mL). The organic layer was washed with saturated sodium chloride and concentrated to obtain a solid. The crude product was subjected to silica gel column chromatography, eluting with petroleum ether:ethyl acetate:methanol (2:2:6 drops), to give 12a as a pale yellow solid.

[0046] Compound 11 (1.19mmol) and TEA (0.18g, 1.78mmol) were successively added to 10mL dry DMF under ice-free conditions, stirred for a period of time, and p-nitrobenzenesulfonyl chloride dissolved in 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com