Preparation technology of polystyrene microsphere for reinforcing turbidimetric reagent

A technology for the preparation of polystyrene microspheres, which is applied in the field of polymer microsphere materials, can solve the problems of increased reagent costs, easy coagulation, and increased other raw materials, and achieve good emulsion stability, improved cross-linking efficiency, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, but the embodiments of the present invention are not limited to the following examples.

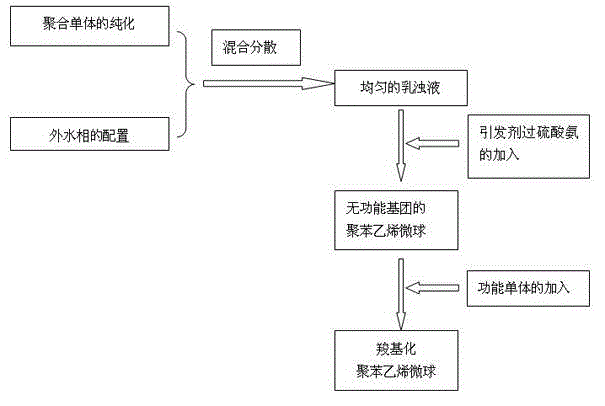

[0036] In the preparation process of polystyrene microspheres applied to enhanced turbidimetric reagents in this embodiment, the core technology is embodied in two aspects of raw material formula and process flow.

[0037] Raw material formula material ratio is as follows:

[0038] External water phase: sodium dodecyl sulfate (SDS) 0.1-2 g; polyethylene glycol (PEG-6000), namely polyethylene glycol with a molecular weight of 6000 2-16 g; sodium chloride (NaCl) 0.1- 3 g; purified water (H 2 O) 400-600 mL.

[0039] Polymerized monomer: styrene (St) 50-100 mL; divinylbenzene (DVB) 0.5-1.0 mL.

[0040] Functional monomer: ethyl acrylate 2-16 mL, borate borax buffer 10-60 mL.

[0041] As the above-mentioned proportioning of the formula of the present invention, it can be scaled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com