Single-component bonding sealing type silicone adhesive for solar battery assembly

A solar cell, bonding and sealing technology, which is applied in the field of sealants, can solve the problems of deketoxime odor and poor water vapor barrier effect, and achieve the effects of preventing cracking, promoting rapid curing, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

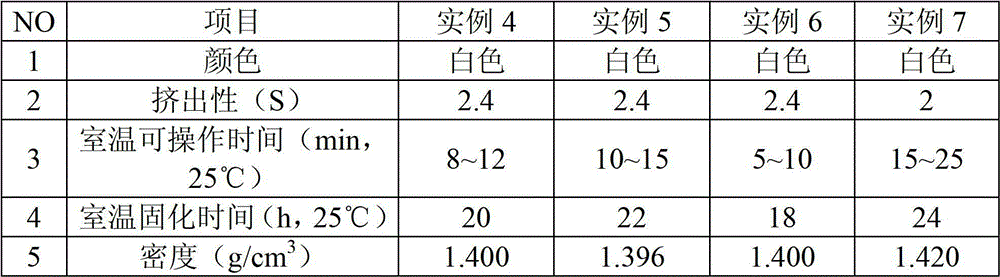

Examples

Embodiment 1

[0029] Implementation Example 1: Dehydrate 100 parts of castor oil at 110°C for 2 hours, add 5.5 parts of hexamethylene diisocyanate into a reactor equipped with a stirrer, a condenser of a drying tube, a nitrogen inlet tube and a thermometer after cooling , raise the temperature to 65~80°C under stirring with nitrogen gas, and stop when the NCO (isocyanate group) value reaches the predetermined range (those skilled in the art can clearly define the specific value of this range, and obtain it by chemical titration). The reaction is to obtain NCO group-terminated polyurethane prepolymer. Then, 1.75 parts of N-phenyl-γ-aminopropyltrimethoxysilane end-capping agent was added dropwise to the system. After the reaction was complete, SPU-1 was obtained, which was sealed and stored for future use.

Embodiment 2

[0030] Implementation Example 2: 100 parts of castor oil was dehydrated at 110°C for 2 hours, and after cooling, 5.5 parts of hexamethylene diisocyanate were added to a reactor equipped with a stirrer, a condenser of a drying tube, a nitrogen gas inlet tube and a thermometer , the temperature is raised to 65~80°C under nitrogen gas stirring, and the reaction is stopped when the NCO value reaches the predetermined range to obtain the NCO group-terminated polyurethane prepolymer. Then, 1.75 parts of γ-mercaptopropyltrimethoxysilane end-capping agent was added dropwise to the system. After the reaction was complete, SPU-2 was obtained, which was sealed and stored for future use.

Embodiment 3

[0031]Implementation Example 3: 100 parts of castor oil was dehydrated at 110°C for 2 hours, and after cooling, 5.5 parts of hexamethylene diisocyanate were added to a reactor equipped with a stirrer, a condenser of a drying tube, a nitrogen gas introduction tube and a thermometer , the temperature is raised to 65~80°C under nitrogen gas stirring, and the reaction is stopped when the NCO value reaches the predetermined range to obtain the NCO group-terminated polyurethane prepolymer. Then, 1.75 parts of γ-ureidopropyltrimethoxysilane capping agent was added dropwise to the system. After the reaction was complete, SPU-3 was sealed and stored for later use.

[0032] It can be seen from the above-mentioned Examples 1-3 that the partially silylated polyurethane resin is a polyurethane prepolymer partially blocked by various silane-blocking agents, and its synthetic raw materials mainly include flexible long-chain fatty polyols (such as castor oil ), diisocyanates (such as hexameth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com