Method for preparing polyether amide material

A polyether amide and polyether amine technology, which is applied in the field of preparing polyether amide materials, can solve the problems of low glass transition temperature, difficult regulation and optimization, complex reaction system, etc., and achieves excellent performance, simple and easy operation, high The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

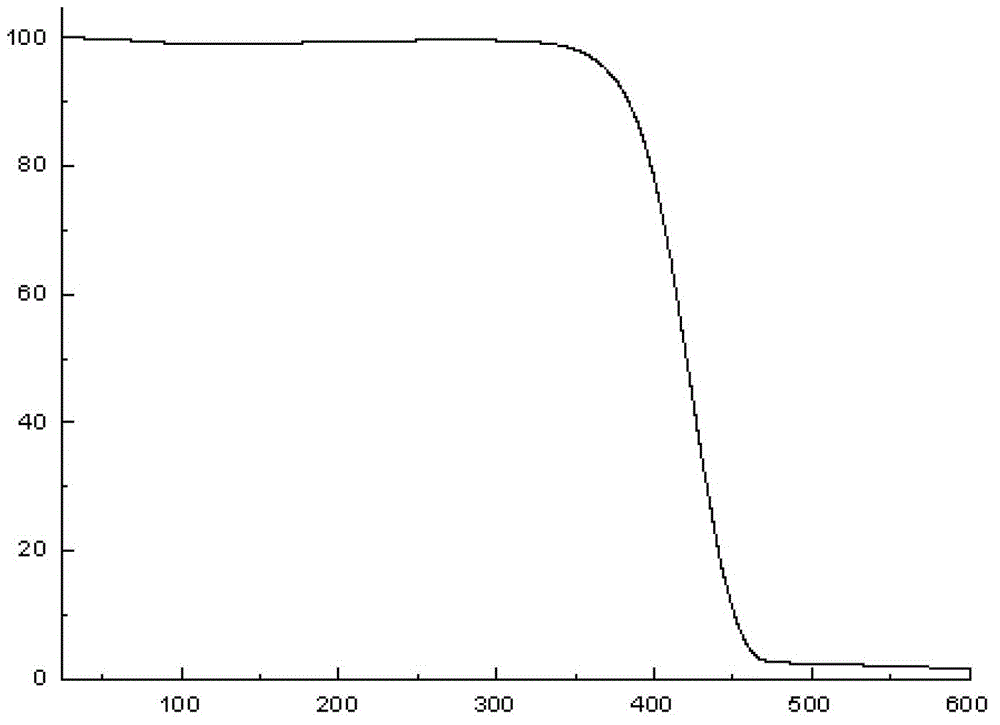

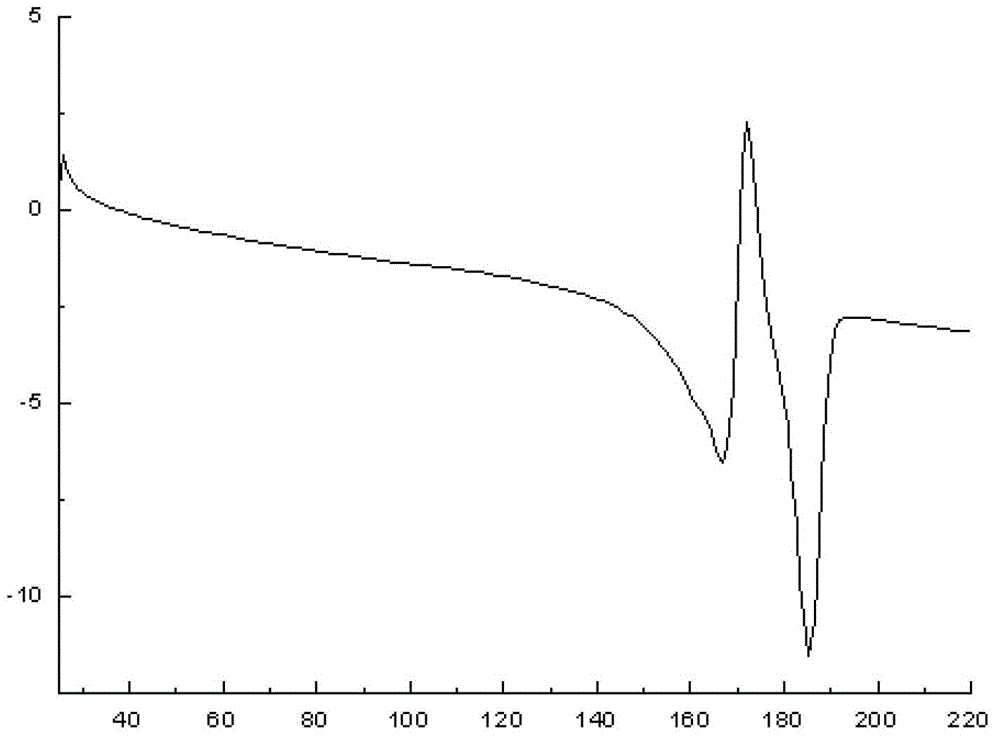

[0029] In the method for preparing polyether amide materials described in the present invention, in order to promote the reaction to carry out as far as possible thoroughly and improve the molecular weight of product polyether amide, and reduce the degree of dispersion of macromolecule product, must control the quality of salt, pre- Several key factors such as polycondensation time, stirring speed, post-polycondensation time, and water removal.

[0030] Salt quality: When synthesizing polyetheramine-diacid salt, it is necessary to prepare the ethanol solution of polyetheramine in advance to control the speed of the salt-forming reaction; Stir until the ethanol solution of the diacid is completely dissolved; then use a constant pressure dropping funnel to slowly drop the ethanol solution of polyetheramine into the ethanol solution of the diacid; the whole process is completed under the condition of a constant temperature water bath at 40~50°C , It can be seen that factors such ...

Embodiment 1

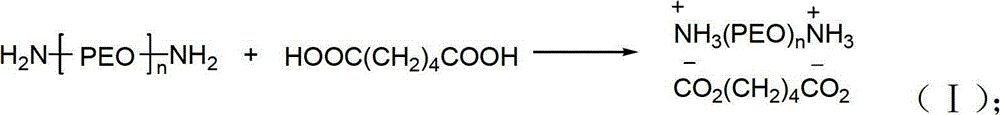

[0034] Embodiment one: a kind of method for preparing polyether amide material, comprises the following steps:

[0035] Preparation of polyetheramine-diacid salt:

[0036] (1) Measure 250ml of absolute ethanol in a 500ml container, and keep it in a constant temperature water bath at 40°C for 30 minutes; weigh 46.836g of adipic acid (with a carboxyl content of 0.6mol), and gradually add the adipic acid to the In 250ml absolute ethanol, make it fully dissolve, obtain the ethanol solution of adipic acid, stirring speed is 200 rev / mins;

[0037] (2) Weigh 53.333g of EDR-176 (the content of amine group is 0.6mol), and dilute it with 50mL of absolute ethanol to obtain the ethanol solution of EDR-176;

[0038] (3) Slowly drop the ethanol solution of EDR-176 into the ethanol solution of adipic acid under the condition of stirring with constant pressure dropping funnel, the dropping speed is 1 drop / second, and the dropping temperature is 40°C; , continue to stir for 1 hour, and the s...

Embodiment 2

[0050] Embodiment two: a kind of method for preparing polyether amide material, comprises the following steps:

[0051] Preparation of polyetheramine-diacid salt:

[0052] (1) Measure 250ml of absolute ethanol in a 500ml container and keep it in a constant temperature water bath at 50°C for 30 minutes; weigh 46.836g of adipic acid (with a carboxyl content of 0.6mol), and gradually add the adipic acid to the In 250ml absolute ethanol, make it fully dissolve, obtain the ethanol solution of adipic acid, stirring speed is 300 rev / mins;

[0053] (2) Weigh 53.333g of EDR-176 (the content of amine group is 0.6mol), and dilute it with 50mL of absolute ethanol to obtain the ethanol solution of EDR-176;

[0054] (3) Slowly drop the ethanol solution of EDR-176 into the ethanol solution of adipic acid under the condition of stirring with constant pressure dropping funnel, the dropping speed is 2 drops / second, and the dropping temperature is 50°C; , continue to stir for 1.5 hours at a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com