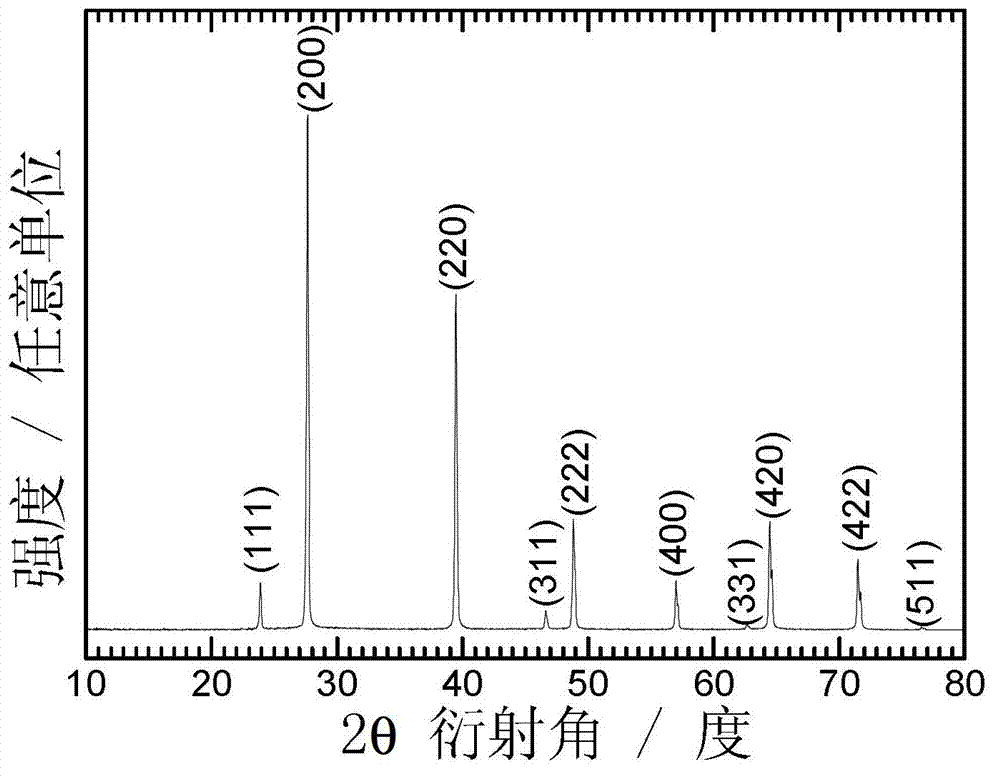

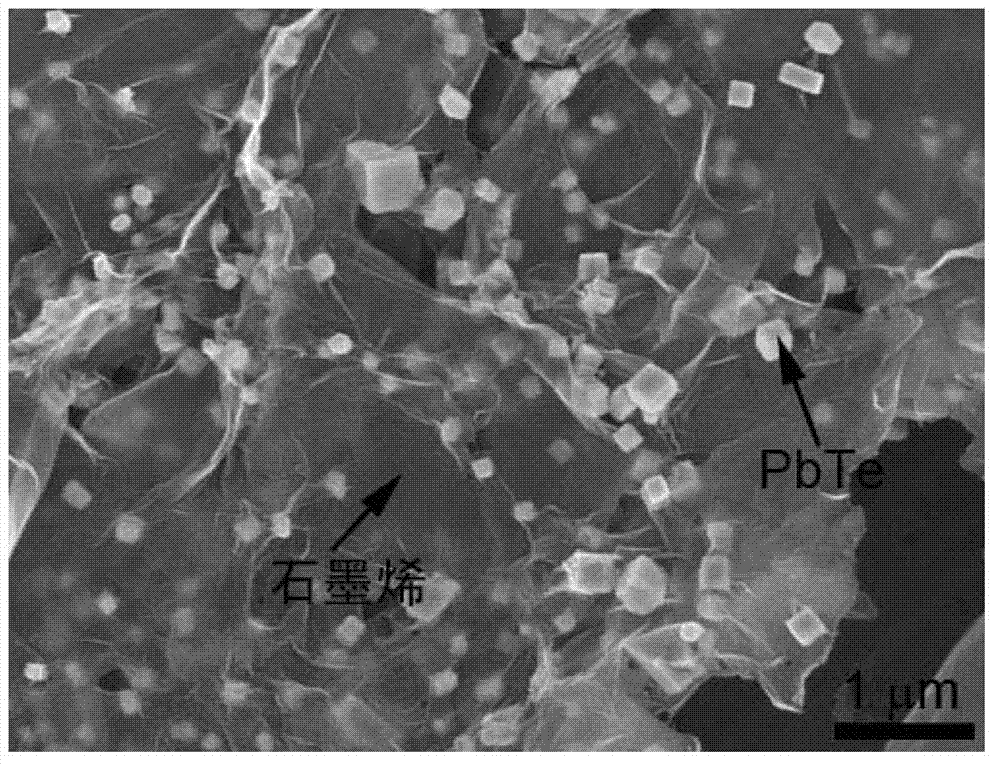

PbTe cubic particle/grapheme composite material and preparation method and application thereof

A technology of cubic particles and composite materials, used in thermoelectric devices with thermal changes in dielectric constant, etc., can solve the problems of inability to reflect the advantages of nanomaterials, easy agglomeration of nanocrystalline particles, weakening of phonon scattering, etc., to promote effective scattering, improve Thermoelectric performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) The analytically pure PbCl 2 And Te powder, according to the proportion of Pb:Te atomic ratio 1:1, mix in absolute ethanol, make the mixed solution that the concentration of PbTe is 0.015mol / L, the mixed solution volume is 80 milliliters.

[0033] 2) Add 20 mg of GO to the mixture in step 1) and fully ultrasonically disperse it, then place it in a high-pressure reactor with a capacity of 100 ml (filling degree 80%, volume percentage), and then add 0.5 g of reducing agent NaBH to the solution 4 , and then add 6M NaOH aqueous solution to adjust the pH value to 10, and then seal it immediately.

[0034] 3) Heating the reactor to 180°C and reacting for 24 hours.

[0035] 4) Naturally cool to room temperature after the reaction, collect the powdery reaction product at the bottom of the kettle, wash it with deionized water and absolute ethanol alternately and repeatedly for several times, then vacuum dry the powder at 110°C for 12 hours to obtain a composite material powd...

Embodiment 2

[0038] 1) Analytical pure Pb(NO 3 ) 2 and Na 2TeO 3 , according to the proportion of Pb:Te atomic ratio of 1:1 and then mixed in deionized water to prepare a mixed solution with a concentration of 0.03 mol / L in terms of PbTe, and the volume of the mixed solution was 80 ml.

[0039] 2) Add 24 mg of GO to the mixture in step 1) and fully ultrasonically disperse it, then place it in a high-pressure reactor with a capacity of 100 ml (filling degree 80%, volume percentage), and add 2.3 g of reducing agent KBH to the solution 4 , and then add 6M KOH aqueous solution to adjust the pH value to 11, and then seal it immediately.

[0040] 3) Heating the reactor to 140°C and reacting for 48 hours.

[0041] 4) Naturally cool to room temperature after the reaction, collect the powdery reaction product at the bottom of the kettle, wash it with deionized water and absolute ethanol alternately and repeatedly for several times, then vacuum dry the powder at 110°C for 12 hours to obtain a co...

Embodiment 3

[0044] 1) will analyze pure PbSO 4 and K 2 TeO 3 According to the ratio of Pb:Te atomic ratio of 1:1, mix in anhydrous ethylene glycol to prepare a mixed solution with a concentration of 0.09 mol / L in terms of PbTe, and the volume of the mixed solution is 80 ml.

[0045] 2) Add 24 mg of GO to the mixture in step 1) and fully ultrasonically disperse it, then place it in a high-pressure reactor with a capacity of 100 ml (filling degree 80%, volume percentage), and add 3 grams of reducing agent NaBH to the solution 4 , then add 6M NaOH aqueous solution to adjust the pH value to 11 and seal immediately.

[0046] 3) Heating the reactor to 220°C and reacting for 36 hours.

[0047] 4) Naturally cool to room temperature after the reaction, collect the powdery reaction product at the bottom of the kettle, wash it with deionized water and absolute ethanol alternately and repeatedly for several times, then vacuum dry the powder at 110°C for 12 hours to obtain a composite material powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com