Microcapsule preparation, preparation method and application

A technology of microcapsules and preparations, applied in the field of agricultural microorganisms, can solve the problems of high requirements for microcapsule equipment, unsuitable for large-scale production, weak adaptability to the environment, etc. The effect of easy transportation and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

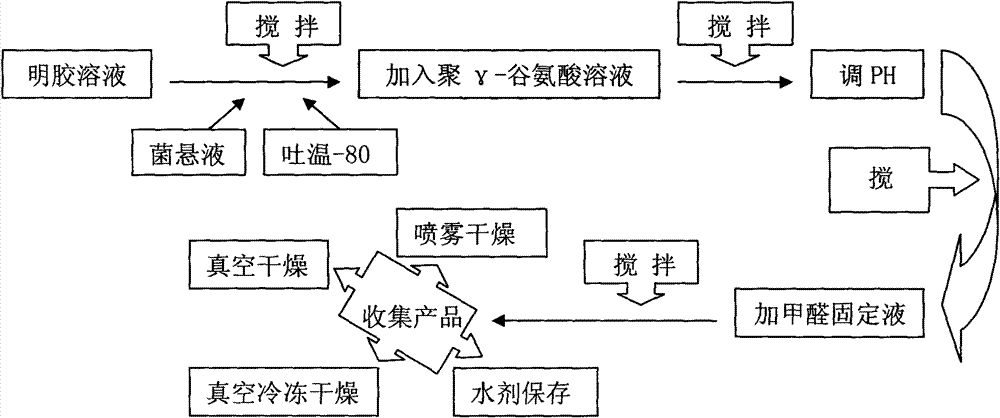

Method used

Image

Examples

Embodiment 1

[0064] 1. The isolation and screening process of Bacillus subtilis 3-10;

[0065] One of the microorganisms used in the capsule core of the microcapsule preparation of the present invention is a biocontrol bacterium Bacillus subtilis which is obtained by separating and screening from the vegetable garden soil of the Huazhong Agricultural University campus in the Shizishan District, Wuchang, Wuhan, Hubei Province. Bacillus subtilis 3-10, which was sent to the China Center for Type Culture Collection (CCTCC) in Wuhan University, Wuhan, Hubei Province on March 30, 2011, and its preservation number is CCTCC NO: M2011100.

[0066] 2. Isolation, identification and mycological characteristics of Bacillus subtilis 3-10

[0067] (1) Isolation and identification of Bacillus subtilis 3-10

[0068] A biocontrol bacterium Bacillus subtilis (Bacillus subtilis) 3-10 suitable for the prevention and treatment of watermelon wilt of the present invention was isolated and screened on the vegetab...

Embodiment 2

[0098] According to the method described in Example 1, in this example, the microorganism used for the capsule core is Bacillus mucilaginosus, preservation number: ACCC NO: 10168, purchased from China Agricultural Microorganism Culture Collection Center ( Address: No. 12, Zhongguancun South Street, Haidian District, Beijing), its spores and bacteria are obtained through fermentation.

[0099] The fermentation medium formula and conditions are as follows:

[0100] Medium: soybean meal 42g / L, cornstarch 8g / L, CaCO 3 1g / L, K 2 HPO 4 0.25g / L, FeCl 3 0.015g / L, magnesium sulfate heptahydrate 2.4g / L; Supplement distilled water to 1000ml; pH 7.0-7.2; Sterilize according to conventional methods (121°C high-pressure steam sterilization for 20min).

[0101] Fermentation conditions: shake flask 100ml / 500ml liquid volume, 28°C, shaker 180r / min for 24 hours.

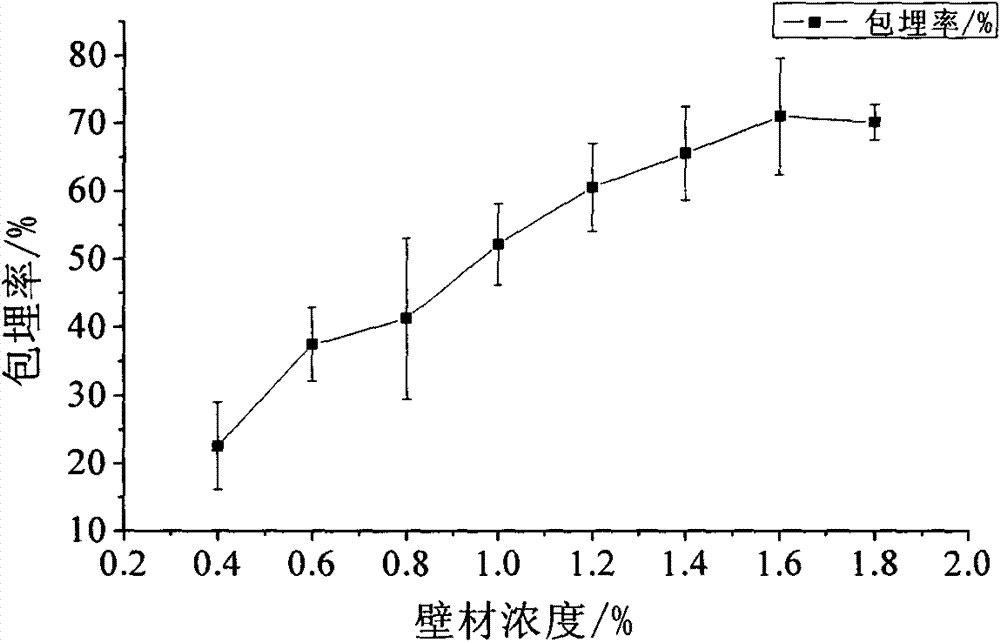

[0102] Wherein the concentration of poly-γ-glutamic acid in step (1) and gelatin solution is all 1.5%, the consumption of gel...

Embodiment 3

[0107] According to the method described in Example 1, in this example, the microorganism used for the cystic core is Bacillus megaterium (Bacillus megaterium), preservation number: ACCC NO: 10010, purchased from China Agricultural Microorganism Culture Collection Center (address: No. 12, Zhongguancun South Street, Haidian District, Beijing), and its spores and thallus are obtained by fermentation.

[0108] The fermentation medium formula and conditions are as follows:

[0109] Medium: cornstarch 20.0g, peptone 15.0g, soybean meal 30.0g, KH 2 PO 4 2.0g, calcium carbonate 2.0g, magnesium sulfate 1.0g, manganese sulfate 0.5g; add distilled water to 1000ml; pH pH7.5; sterilize according to conventional methods (121°C autoclaving for 20min).

[0110] Fermentation conditions: shake flask 100ml / 500ml liquid volume, 28°C, shaker 180r / min for 36 hours.

[0111] Wherein the concentration of the poly-γ-glutamic acid in the step (1) and the gelatin solution is 2.5%, the consumption of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com