Preparation method of palladium catalyst,

A palladium catalyst and reaction technology, which is applied in the fields of electrochemistry and the environment, can solve the problems of large amount of metal usage, complex catalyst components, and low performance, and achieve the effects of uniform distribution, high metal reduction efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

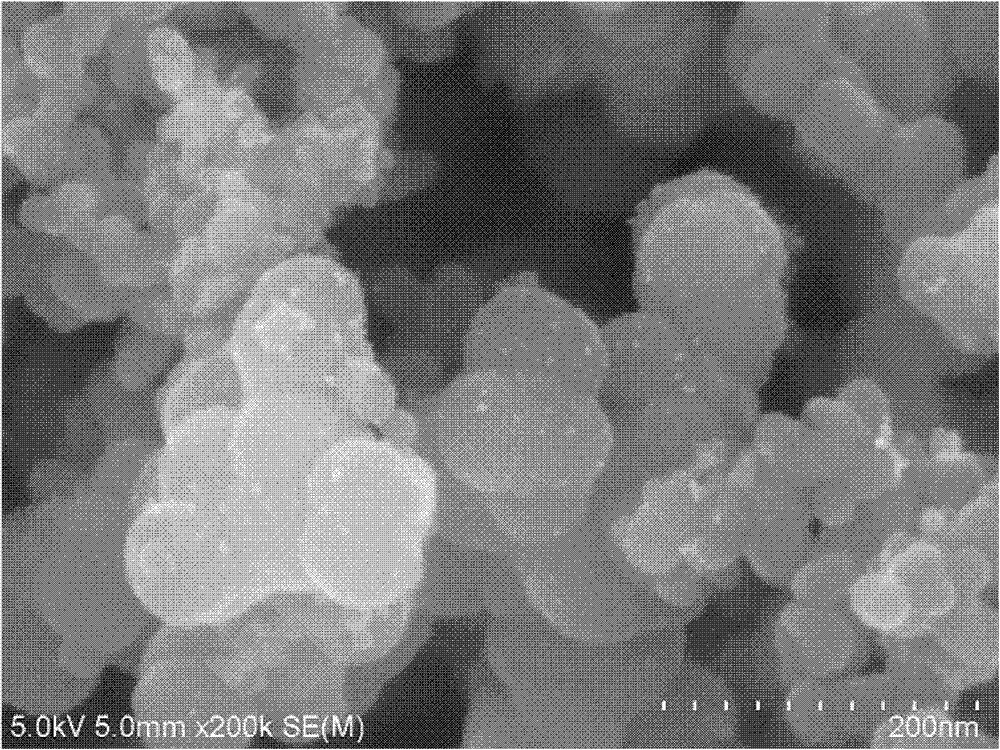

Embodiment 1

[0048] 1. Preparation of pretreated carbon support

[0049] 1) Active carbon powder (5g) is joined in the there-necked flask of 250mL, and add magnetic rotor, then add the concentrated sulfuric acid solution of 25mL concentrated nitric acid solution and 75mL, wherein, the mass percentage concentration of concentrated nitric acid solution is 65%, the concentrated sulfuric acid solution The mass percentage concentration is 98%, and the particle size of activated carbon powder is 20-70nm;

[0050] 2) Stir on a constant temperature magnetic stirrer, heat up to 60°C, carry out oxidation reaction at 60°C for 1 hour to increase the amount of oxygen-containing functional groups on the surface of the carbonaceous support, then cool to room temperature (20°C) and filter, the filter residue Wash with deionized water until the washing liquid is neutral (ie, the pH value of the effluent after washing is 7.0).

[0051] 3) drying the washed filter residue at 70° C. to a constant weight to o...

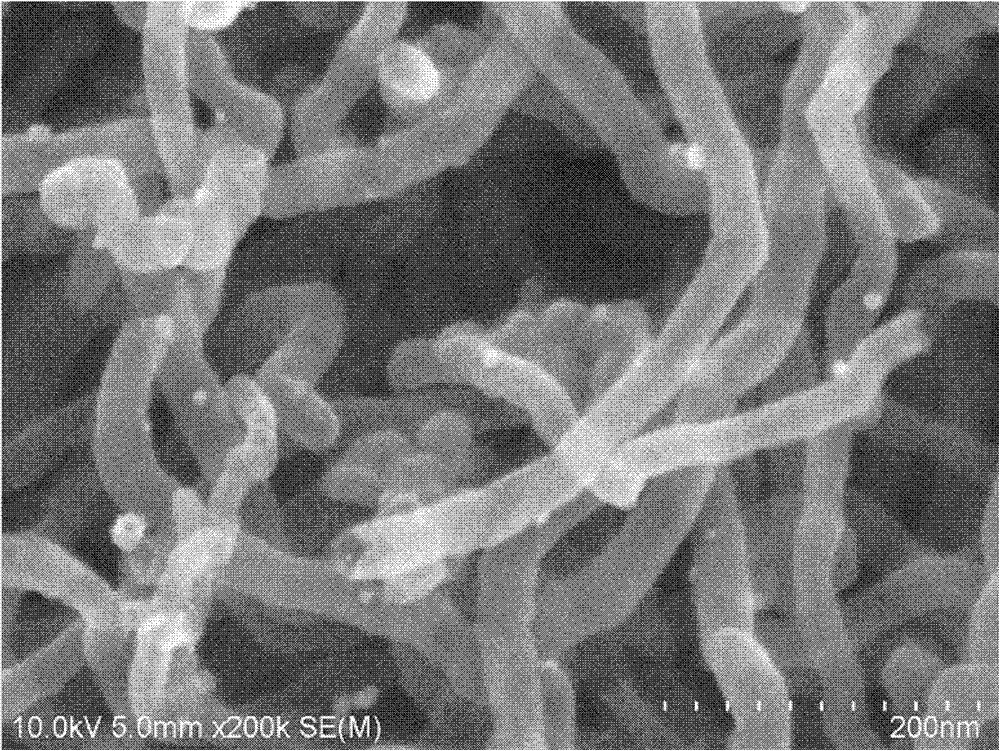

Embodiment 2

[0065] 1. Preparation of pretreated carbon support

[0066] 1) Add carbon nanotubes (5g) into a 250mL three-necked flask, add a magnetic rotor, then add 20mL of nitric acid solution and 80mL of sulfuric acid solution, wherein the mass percent concentration of the nitric acid solution is 60%, and the mass percent of the sulfuric acid solution The concentration is 80%, the diameter of carbon nanotubes is 40-60nm, and the length is 1-2μm;

[0067] 2) Stir on a constant temperature magnetic stirrer, and heat up to 65°C, carry out oxidation reaction at 65°C for 1.5h, then cool to room temperature (25°C) and filter, and wash the filter residue with deionized water until the washing liquid is medium (i.e. the pH of the washed effluent is 7.0).

[0068] 3) drying the washed filter residue at 60° C. to a constant weight to obtain a pretreated carbonaceous carrier.

[0069] The oxygen-containing groups on the surface of the pretreated carbonaceous support were measured by Boehm titrat...

Embodiment 3

[0082] 1. Preparation of pretreated carbon support

[0083] 1) Add carbon nanotubes (5g) into a 250mL three-necked flask, add a magnetic rotor, then add 33.3mL of concentrated nitric acid solution and 66.7mL of concentrated sulfuric acid solution, wherein the mass percent concentration of the concentrated nitric acid solution is 65%, The mass percent concentration of the concentrated sulfuric acid solution is 60%, the diameter of the carbon nanotube is 40-60nm, and the length is 1-2μm;

[0084]2) Stir on a constant temperature magnetic stirrer, heat up to 55°C, carry out an oxidation reaction at 55°C for 3 hours to increase the amount of oxygen-containing functional groups on the surface of the carbonaceous support, then cool to room temperature (20°C) and filter, The filter residue was washed with deionized water until the washing liquid was neutral (that is, the pH value of the effluent after washing was 7.0).

[0085] 3) drying the washed filter residue at 80° C. to a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com