Method for preparing conductive polymer composite film

A conductive polymer, composite film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor controllability, low film stability, complex process, etc., to achieve uniformity Good, large specific volume, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

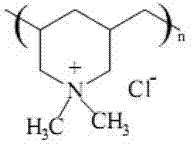

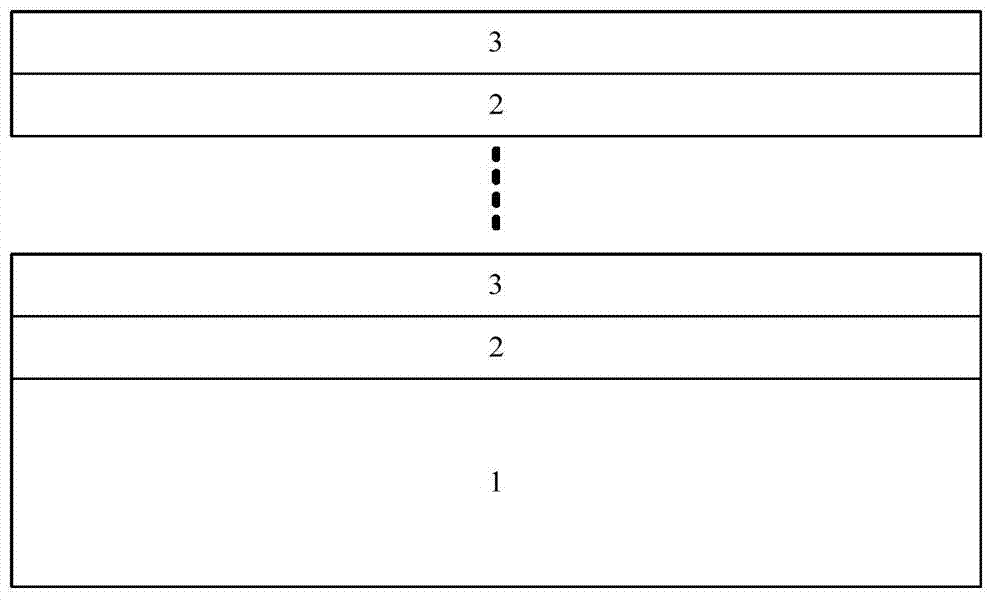

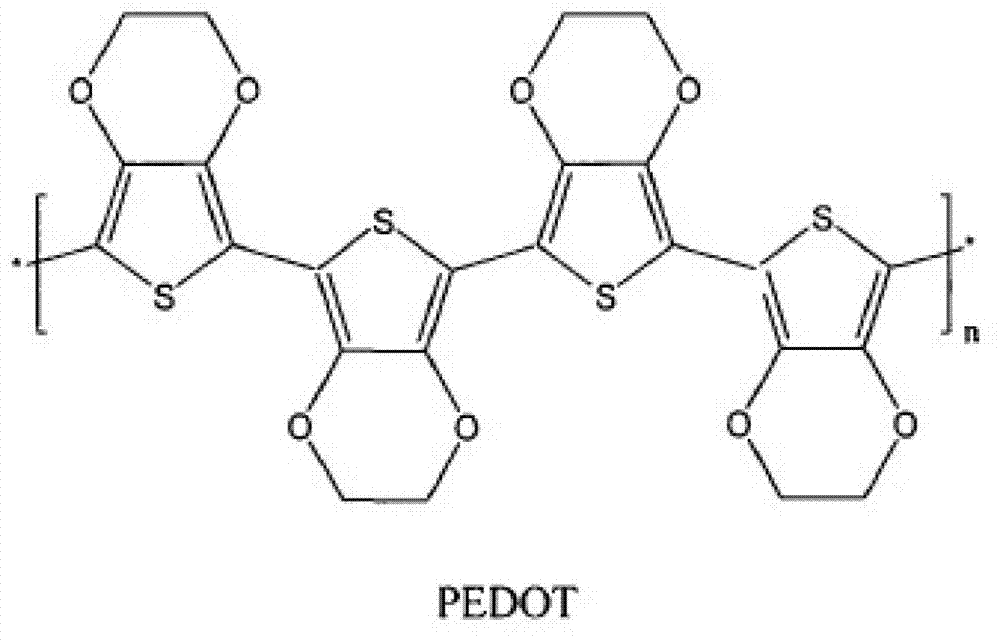

[0028] Put the cleaned quartz and ITO substrates into 0.5mg / ml polydimethyldiallyl ammonium chloride solution and let them stand for 20 minutes, then take out the substrates, wash them with deionized water, and then dry them with nitrogen Then the substrate is immersed in the polyethylenedioxythiophene aqueous solution that added the total volume fraction 7% dimethyl sulfoxide and the concentration is 1mg / ml and left standstill for 20 minutes, then the substrate is taken out, cleaned with deionized water, and then Blow dry with nitrogen; repeat the above alternate steps 42 times in sequence to obtain a polymer film with 42 layers of film; anneal the prepared multilayer composite film at 150° C. for 15 minutes. The electrical conductivity of the composite thin film on the quartz substrate measured by four probes is 28.7S / cm. At 0.5mol / L H 2 SO 4 In the electrolyte, the three-electrode system tests the composite film on the ITO substrate, and its specific capacity can reach 15...

example 2

[0030] Put the cleaned quartz and ITO substrate into 0.6mg / ml polydimethyldiallylammonium chloride solution and let it stand for 20 minutes, then take out the substrate, wash it with deionized water, and blow it dry with nitrogen Then the substrate was immersed in the polystyrene sulfonic acid doped polyethylenedioxythiophene aqueous solution added with a total volume fraction of 7% dimethyl sulfoxide and the concentration was 0.3mg / ml and left to stand for 20 minutes, then the substrate was taken out , after cleaning with deionized water, and then drying with nitrogen; repeating the above alternate steps 42 times in turn to obtain a polymer film with 42 layers of film; annealing the prepared multilayer composite film at 150 ° C for 15 minutes. The electrical conductivity of the composite thin film on the quartz substrate was measured by four probes to be 18.7S / cm. At 0.5mol / L H 2 SO 4 In the electrolyte, the three-electrode system tests the composite film on the ITO substra...

example 3

[0032] Put the cleaned quartz and ITO substrate into 0.6mg / ml polydimethyldiallylammonium chloride solution and let it stand for 20 minutes, then take out the substrate, wash it with deionized water, and blow it dry with nitrogen Then the substrate was immersed in the polyethylene dioxythiophene aqueous solution doped with polystyrenesulfonic acid with a concentration of 0.3 mg / ml added with a total volume fraction of 10% dimethyl sulfoxide and left to stand for 20 minutes, then the substrate was taken out , after cleaning with deionized water, and then drying with nitrogen; repeating the above alternate steps 42 times in turn to obtain a polymer film with 42 layers of film; annealing the prepared multilayer composite film at 150 ° C for 15 minutes. The conductivity of the composite thin film on the quartz substrate was measured to be 12.8 S / cm by four probes. At 0.5mol / L H 2 SO 4 In the electrolyte, the three-electrode system tests the composite film on the ITO substrate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com