Sewage and sludge treatment method for achieving good biological phosphorus removal and improving acid production of sludge

A biological phosphorus removal and sludge treatment technology, applied in biological sludge treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increasing operating costs, reduce operating costs, reduce exposure Air volume, achieve the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

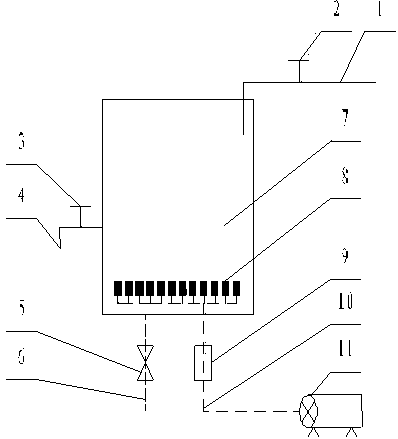

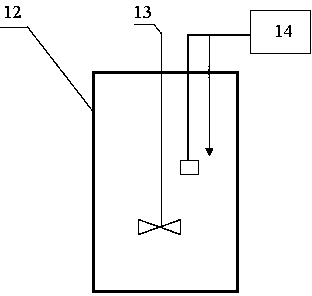

[0027] Such as figure 1 As shown, the sewage treatment plant is a common sequencing batch reactor, such as figure 2 As shown, the residual sludge acid production device used is an alkaline fermentation tank, and its operation method is carried out according to the following steps:

[0028] 1. Open the water inlet valve 2, and the sewage enters the main body 7 of the sequencing batch reactor from the water inlet pipe 1. After the water inlet is completed, close the water inlet valve 2.

[0029] 2. After the water intake is completed, turn on the air compressor 11 for aerobic aeration, and the aerobic aeration time is 4 hours.

[0030] 3. During aerobic aeration for 1 hour, open the sludge discharge valve 5 to discharge a certain amount of mud-water mixture, so that the concentration of activated sludge in the reactor is 3000 mg·L -1 Around, the sludge sludge age is about 12d. After the discharged mud-water mixture settles for 0.5 hours, the supernatant is returned to the ma...

Embodiment 2

[0042] According to the operating method of Example 1, the operating effect of the anaerobic / aerobic process for treating urban domestic sewage and the comparison of the acid production of the obtained residual sludge. Influent COD is 320~350 mg·L -1 , TN is 30~32mg·L -1 , TP is 9~10 mg·L -1 .

[0043] The comparison of sewage treatment results after stable operation is as follows: the effluent COD of the above operation method is 24~32mg·L -1, ammonia nitrogen is 0~3.2mg·L -1 , TP is 0~0.88mg·L -1 ; Anaerobic / aerobic process effluent COD is 22~30mg·L -1 , ammonia nitrogen is 0.26~5.68mg·L -1 , TP is 0~0.79mg·L -1 .

[0044] The remaining sludge obtained was anaerobically fermented in a reactor with a working volume of 600 mL. The fermentation time is exactly the same as the control condition: pH=10±0.1, fermentation time is 4 days, and fermentation temperature is 20±1°C. The results of the obtained organic acids are as follows: the acid production result of the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com