Method for treating ultrahigh-hardness and ultrahigh-conductivity waste water

A technology with high conductivity and conductivity, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of rapid attenuation of treatment effect, troublesome operation and maintenance, and average water production Low conductivity and other problems, to achieve the effect of reducing conductivity, low operating cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

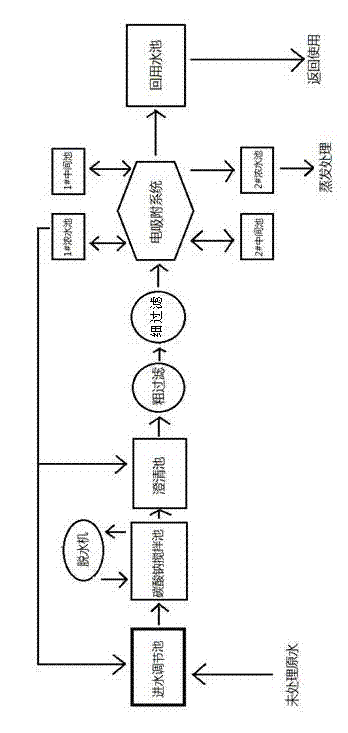

[0042] Such as figure 1 Shown, the method for processing extra-high hardness extra-high conductivity waste water of the present invention is carried out as follows:

[0043] step one:

[0044] Mix all kinds of wastewater into the adjustment tank for 15-20 minutes and then test the total hardness of the water. When the total hardness is <550 mg / L and the pH value is 7.5-11, it can directly enter step 2 for treatment. If the total hardness is ≥550 mg / L , introduce the water into the sodium carbonate stirring tank, add sodium carbonate to the water and stir for 20-35 minutes until the total hardness of the water is <550 mg / L, (after adding sodium carbonate, a large amount of calcium carbonate will be generated in the water), precipitation 3-6 hours, the supernatant after precipitation enters step 2 for treatment, and the rest of the calcium carbonate-containing sludge is pumped to the sludge dewatering machine for solid-liquid separation, and the separated water returns to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com