Thermosetting compound fluorine-containing polyimide resin and preparation method thereof

A polyimide resin and polyimide technology, applied in the field of thermosetting composite fluorine-containing polyimide resin and its preparation, can solve the problems of poor impact toughness, easy microcracks, and high water absorption of composite materials, and achieve Good heat resistance stability, improved solubility and processability, and good moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

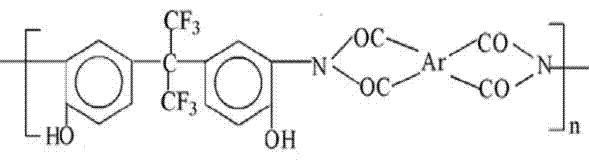

Embodiment 1

[0053] At room temperature, under the protection of nitrogen, put 36.6 g (0.1 mol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane and 460.0 g of N-methylpyrrolidone into the reaction kettle, stir and dissolve After completion, 44.4 g (0.1 mol) of 4,4'-(hexafluoroisopropene) diphthalic anhydride was added, stirred and reacted for 12-24 hours, and a homogeneous, transparent and viscous first resin solution was obtained. Then, add 460.0 g xylene to the first resin solution, azeotropically reflux water-dividing and stirring for 8-12 hours, then react to generate water and xylene to azeotropically distill off to obtain a bisphenol AF-based fluorine-containing polyimide solution. The solid content is 13wt%, namely A component, and the yield is 95%.

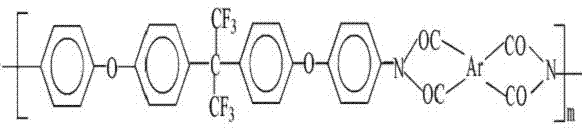

[0054] At room temperature, under nitrogen protection, 51.8 g (0.1mol) of 2,2-bis[4-(4-aminophenoxy)benzene]hexafluoropropane and 450.0 g of N-methylpyrrolidone were put into the reactor, After stirring and dissolving completely...

Embodiment 2

[0061] At room temperature, using nitrogen protection, 36.6 g (0.1mol) 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane and 460.0g N,N-dimethylacetamide were put into the reaction kettle , after stirring and dissolving completely, add 35.4 g (0.1mol) 1,4-bis(trifluoromethyl)-2,3,5,6-benzenetetracarboxylic dianhydride and stir for 12-24 hours to obtain a homogeneous Transparent viscous first resin solution. Then, add 460.0 g of toluene to the first resin solution, azeotropically reflux, separate water, stir and react for 8-12 hours, and then azeotropically distill off the reaction water and toluene to obtain bisphenol AF-based fluorine-containing polyimide solution, containing solid The amount is 12wt%, namely A component, and the yield is 93%.

[0062] At room temperature, under nitrogen protection, 51.8 g (0.1mol) of 2,2-bis[4-(4-aminophenoxy)benzene]hexafluoropropane and 450.0 g of N,N-dimethylacetamide were placed in In the reaction kettle, after stirring and dissolving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com