Epitaxial wafer for 980nm F-P cavity strained quantum well laser with narrow line width and preparation method thereof

A 980nmf-p, quantum well technology, applied in the field of semiconductor lasers, to achieve the effect of low linewidth factor, improved quality, and reduced linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

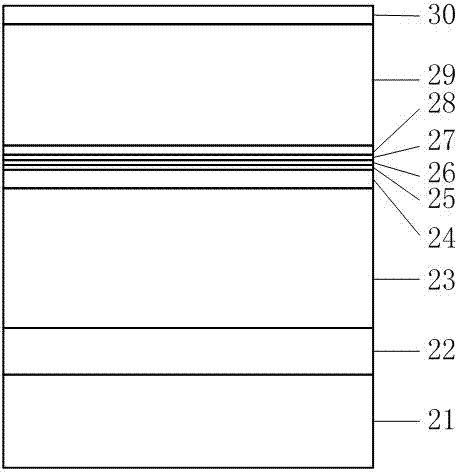

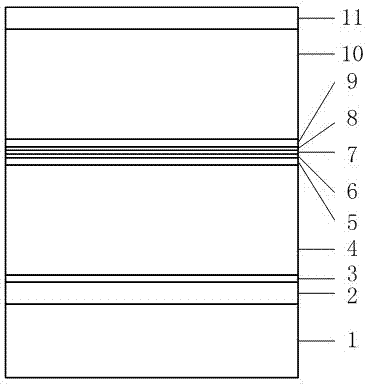

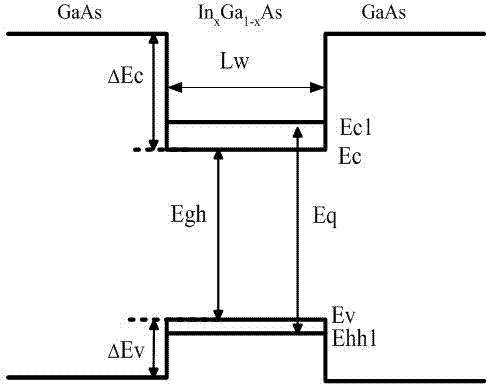

[0085] 1. Preparation of epitaxial wafers:

[0086] The present invention adopts metal organic compound vapor phase epitaxy (MOCVD) equipment produced by AIXTRON company, and the processing steps are as follows:

[0087] 1) With (100) GaAs with a 15-degree bias to the direction as the substrate, SiH is introduced 4 , the thickness of the grown GaAs buffer layer reaches 100nm;

[0088] 2) A transition layer is grown on the GaAs buffer layer, and the material is Al x Ga 1-x As, among them, x 0.3~0.7, the growth thickness of the transition layer is 300nm, SiH is introduced during growth 4 , the Si doping concentration of this epitaxial layer is 1×10 18 cm -3 ;

[0089] 3) On the transition layer, with Al 0.7 Ga 0.3 As is the material, the n-type lower confinement layer is grown, the growth thickness is 1500nm, and SiH is introduced during the growth 4 , the Si doping concentration of this epitaxial layer is 1×10 18 cm -3 ;

[0090] 4) A lower waveguide layer with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com