Water phase preparation method for chain platinum nanosphere by taking octreotide acetate as template

A technology for preparing octreotide acetate and aqueous phase, which is applied in the field of nanomaterials, can solve the problems such as limitation of nanomaterial preparation, inability to form, and inability to control the morphology of reaction products well, and achieves a reaction that is easy to control, small in size, and regular in morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 0.5 mg of octreotide acetate (Shanghai Taishi Biotechnology Co., Ltd.), dissolve it in 1 mL of deionized water, and prepare 0.5 mM octreotide acetate; adjust its pH to 2 with hydrochloric acid (Yongfei Chemical Factory); take the above acetic acid Add 200 μL of octreotide solution, add 5 mM platinum tetrachloride solution (Tianjin Chemical Reagent Factory); put the above prepared solution into a constant temperature shaker in a water bath, incubate at 130 rpm., 13 °C for 26 h, and gradually 25 mM reducing agent dimethylborane (Beijing Zhongsheng Huateng Technology Co., Ltd.) was added dropwise for reduction, so that it changed from light yellow to gray black, and octreotide acetate-chain platinum nanospheres were obtained.

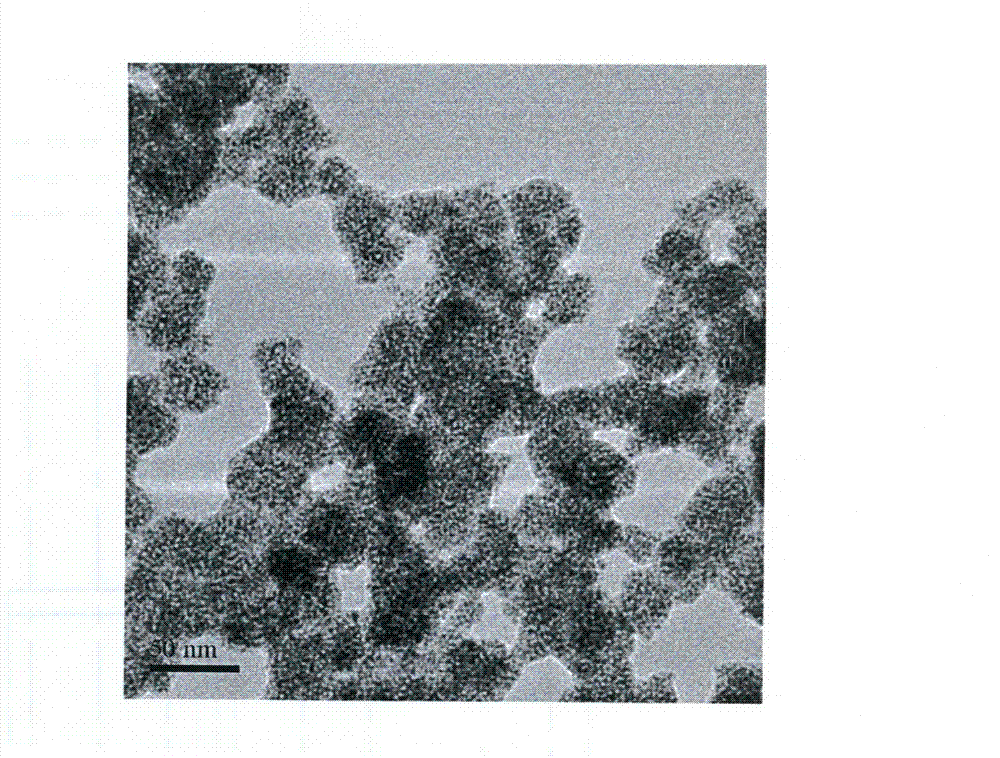

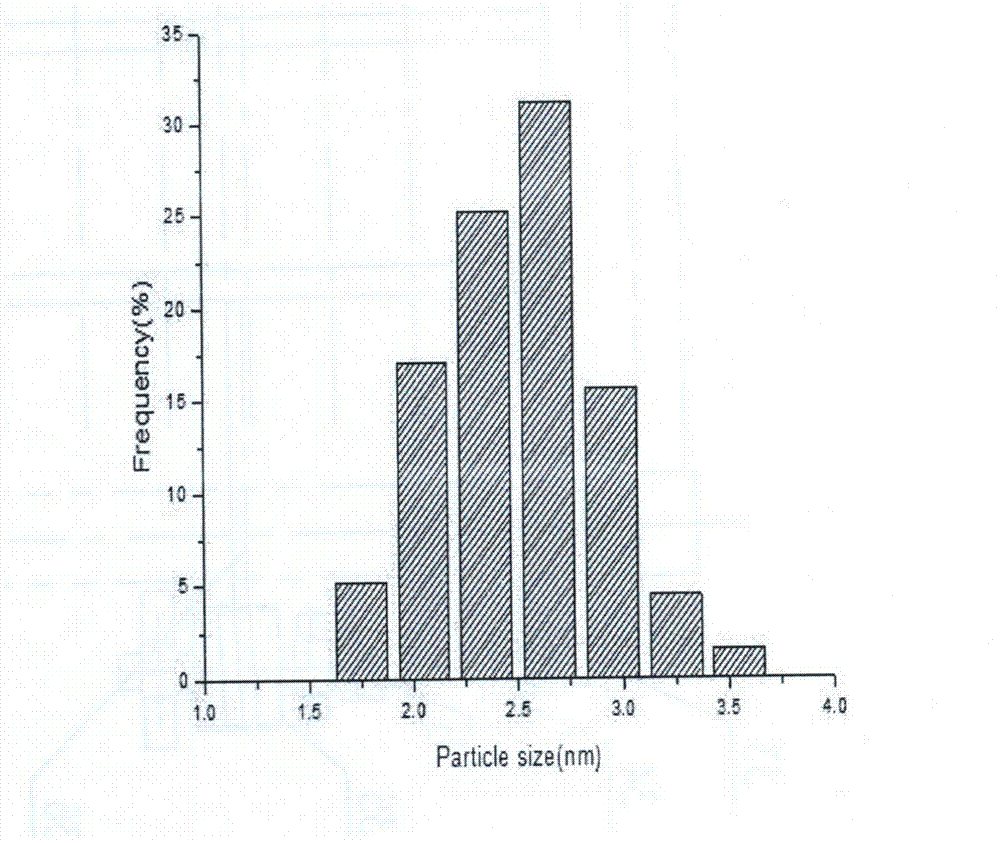

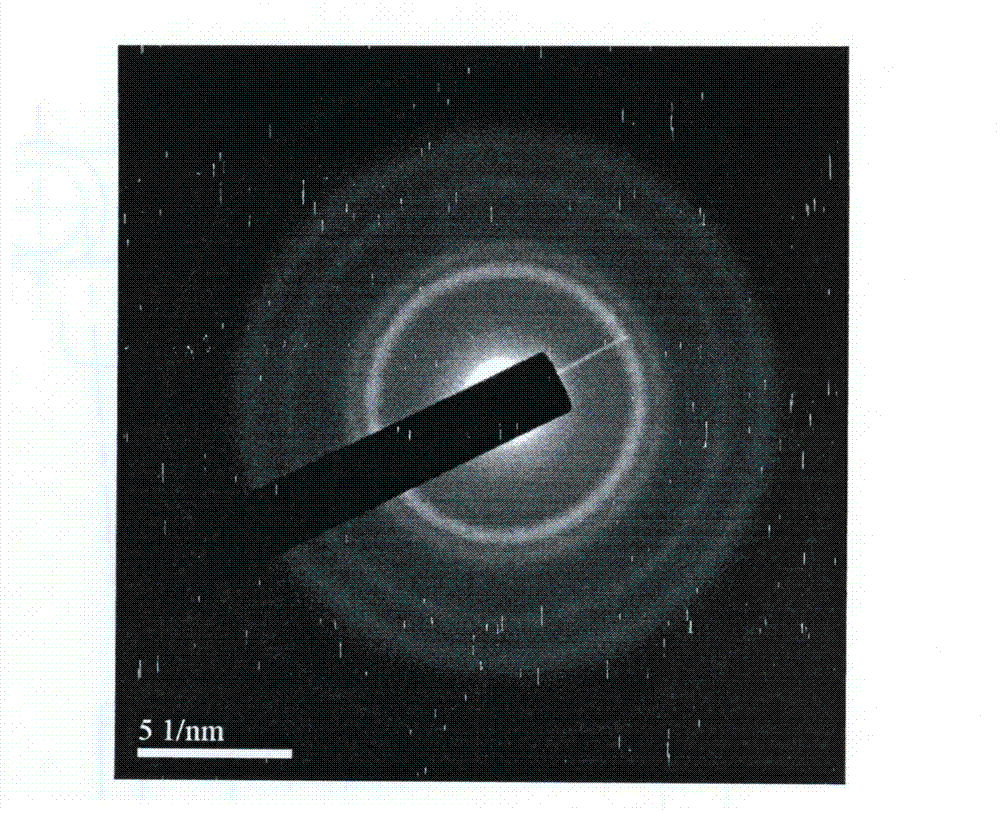

[0024] Such as figure 1 and figure 2 As shown, it can be seen that the diameter of platinum particles is 2.5±0.5 nm, and octreotide acetate is a regular ellipsoid with a diameter of about 55 nm, uniform in size, and can form a streptosphere s...

Embodiment 2

[0028] Take 0.5 mg of octreotide acetate, dissolve it in 1 mL of deionized water, configure 0.5 mM octreotide acetate, adjust its pH to 8 with sodium hydroxide (Tianjin Fengchuan Chemical Reagent Technology Co., Ltd.); take the above octreotide acetate solution 200 μL, add 5 mM platinum tetrachloride solution; put the above-prepared solution into a constant temperature shaker in a water bath, incubate at 100 rpm., 25°C for 20 h, then add 25 mM reducing agent dimethyl boron dropwise The alkane is reduced to make it change from light yellow to gray black, and octreotide acetate-chain platinum nanospheres are obtained.

[0029] Such as Figure 6 and Figure 7 As shown, different pH can change the diameter of octreotide acetate-chain platinum nanospheres, indicating that the morphology of octreotide acetate is controllable. Under alkaline conditions, the diameter of octreotide acetate-chain platinum nanospheres is about 25 nm, and the platinum particles are slightly agglomerated...

Embodiment 3

[0031] Take 0.8 mg of octreotide acetate and dissolve it in 1 mL of deionized water to prepare 0.8 mM octreotide acetate, and adjust its pH to 3 with hydrochloric acid; take 200 μL of the above octreotide acetate solution and add 6.4 mM platinum tetrachloride solution; Put the above-prepared solution into a constant temperature shaker in a water bath, incubate at 170 rpm., 18°C for 24 h, then add 36 mM reducing agent dimethylborane dropwise for reduction, making it change from light yellow to gray The black line means that octreotide acetate-chain platinum nanospheres are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com