Aspergillus sp. strain and application of aspergillus sp. strain to preparation of xylanase

A technology of xylanase and strain, applied to Aspergillus strain and its application field in preparing xylanase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

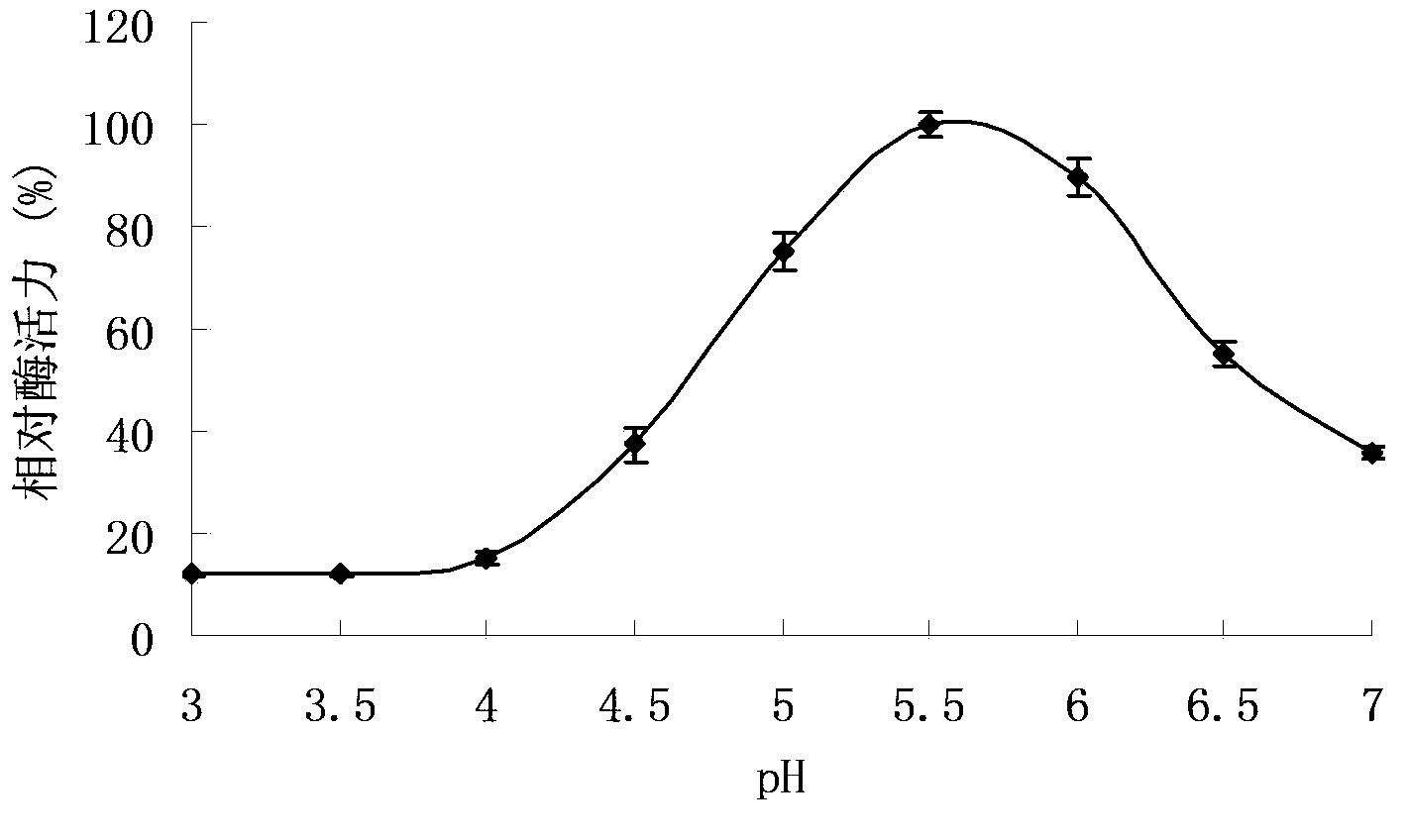

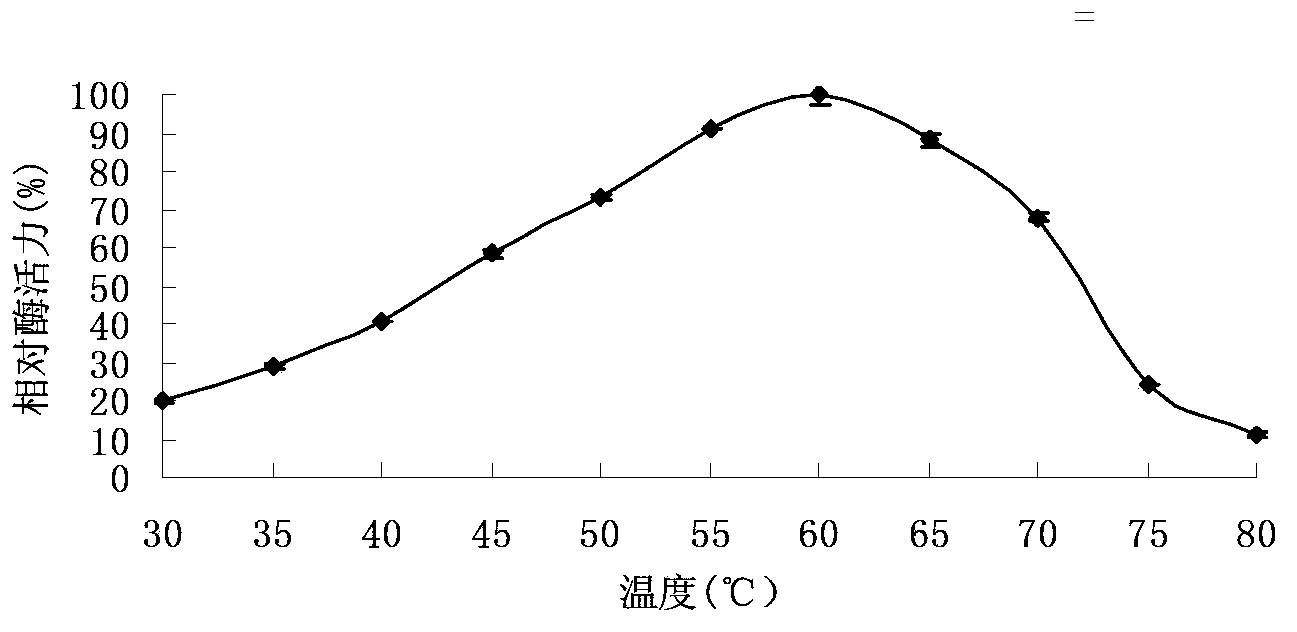

Method used

Image

Examples

Embodiment 1

[0032]In Example 1, Example 2, and Example 3, xylanase activity was determined using 3,5-dinitrosalicylic acid (3,5-dinitrosalicylate, DNS) method (Miller GL. Use of dinitrosalicyclic acid reagent for determination of reducing sugar.Analytical Chemistry, 1959,31:426-428), the specific steps are as follows:

[0033] 1. Dissolve xylose in sterile deionized water to make xylose standard solutions of different concentrations (0.1mg / mL, 0.2mg / mL, 0.3mg / mL, 0.4mg / mL, 0.5mg / mL, 0.6mg / mL, 0.7mg / mL, 0.8mg / mL, 0.9mg / mL); add 1mL DNS to 500μL xylose standard solution, develop color in boiling water bath for 5min, cool to room temperature (25°C), measure light absorption at 540nm ; Obtain the standard curve of light absorbance and xylose concentration. The function formula of the standard curve is y=3.0549x+0.0008(R 2 =0.9990) (y is the light absorption value, x is the concentration of xylose).

[0034] 2. Add 250 μL of 1% birch xylan (Sigma company) solution to the 2mL EP tube, then ...

Embodiment 2

[0051] Embodiment 2, utilize Aspergillus fumigatus strain FC2-2 to prepare xylanase

[0052] 1. Obtaining of fermentation broth

[0053] 1. Preparation of fermentation medium

[0054] Prepare a liquid basic fermentation medium with a pH of 5.5 (recipe as above).

[0055] 2. Preparation of spore solution

[0056] (1) Prepare PDA solid medium and sterilize it at 121°C for 20 minutes.

[0057] (2) Wash the spores of the Aspergillus fumigatus strain FC2-2 obtained in Example 1 on the PDA solid medium plate for 5 days to make a spore suspension, wherein the spore concentration is 1×10 7 individual / mL.

[0058] 3. Obtaining of fermentation broth

[0059] (1) Put 50mL of liquid basic fermentation medium into a 250mL shake flask. Sterilize with damp heat at 121°C for 20 minutes.

[0060] (2) The spore suspension of Aspergillus fumigatus strain FC2-2 obtained in Example 1 was inoculated into the fermentation medium at an inoculum amount (volume percentage) of 1%, and cultured at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com