Array substrate and manufacturing method thereof as well as display equipment

A manufacturing method and array substrate technology, applied in the fields of array substrate, display device, and array substrate manufacturing, can solve the problems of high manufacturing cost and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The method for manufacturing an array substrate provided by an embodiment of the present invention includes a manufacturing process of a thin film transistor, a first transparent electrode, and a second transparent electrode. The first transparent electrode and the second transparent electrode generate a multidimensional electric field. Wherein, the manufacturing process of the first transparent electrode includes:

[0044] Step 1: forming a metal oxide film, which has semiconductor properties.

[0045] Step 2: forming a first transparent electrode by performing metallization treatment on part of the metal oxide thin film, and forming a semiconductor active layer on the part not subjected to the metallization treatment.

[0046] Further, in step 2, "forming the first transparent electrode by performing metallization treatment on part of the metal oxide film" may specifically include: performing metallization treatment on part of the metal oxide film through a plasma pr...

Embodiment 2

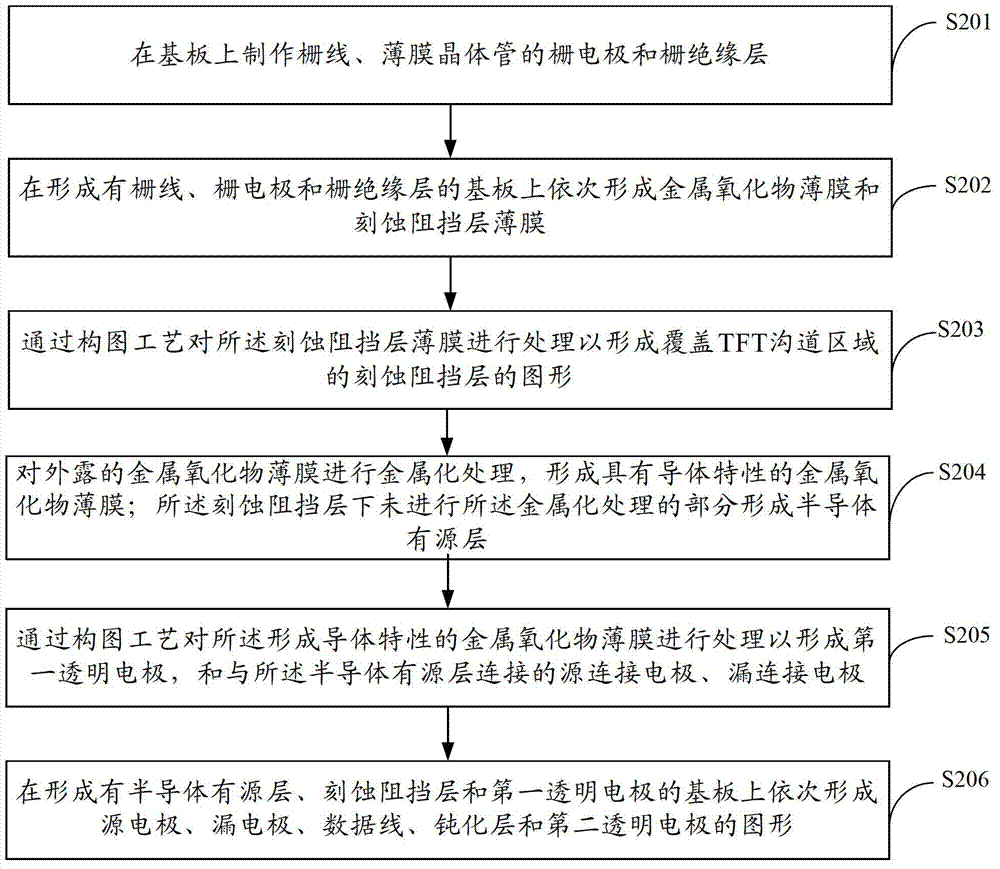

[0050] The manufacturing method of the array substrate provided by the embodiment of the present invention, such as figure 2 As shown, the method specifically includes:

[0051] S201 , fabricating a gate line, a gate electrode and a gate insulating layer of a thin film transistor on a substrate.

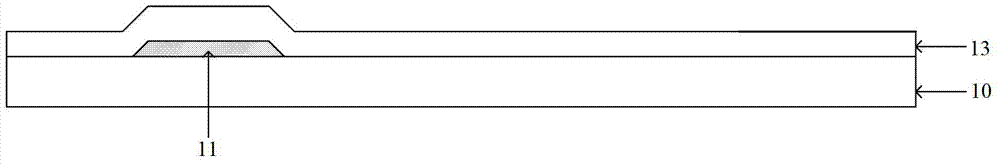

[0052] Exemplary, see image 3 Firstly, a first metal thin film is formed on the substrate 10 (such as a glass substrate or a quartz substrate) by plasma enhanced chemical vapor deposition (PECVD), magnetron sputtering, thermal evaporation or other film forming methods. Wherein, the first metal thin film may be a single-layer thin film formed of metals such as molybdenum, aluminum, aluminum-rubidium alloy, tungsten, chromium, copper, etc., or a multi-layer thin film formed by multi-layer deposition of the above metals. After the photoresist layer is coated on the first metal film, patterning processes such as exposure, development, etching and stripping are carried out through a mas...

Embodiment 3

[0074] The basic process of the manufacturing method of the array substrate provided by the embodiment of the present invention is similar to that of the second embodiment, and reference may be made to the second embodiment.

[0075] The difference between this embodiment and Embodiment 2 is that, relative to S201 of Embodiment 2, S201' of this embodiment includes: Figure 13 As shown, gate lines are formed on the substrate 10 ( Figure 13 (not shown in ), gate electrode 11 , common electrode line 12 is also formed, and then gate insulating layer 13 is formed on substrate 10 .

[0076] Further, the common electrode lines 12, the gate electrodes 11 and the gate lines can be formed through one patterning process.

[0077] The steps after forming the gate lines, gate electrodes and common electrode lines are the same as the steps S202-S205 in the second embodiment, and will not be repeated here.

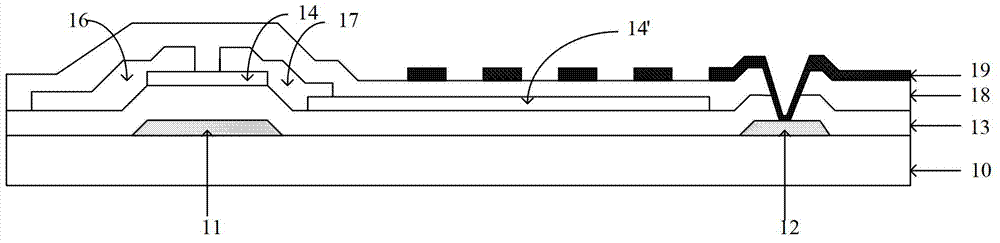

[0078] Patterns of source electrodes, drain electrodes, data lines, passivation l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com