Flexible organic light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and diodes, which is applied in the direction of light-emitting materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc. Poor thermal performance and other problems, to achieve the effect of stable luminous performance, enhanced bonding force, and low surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

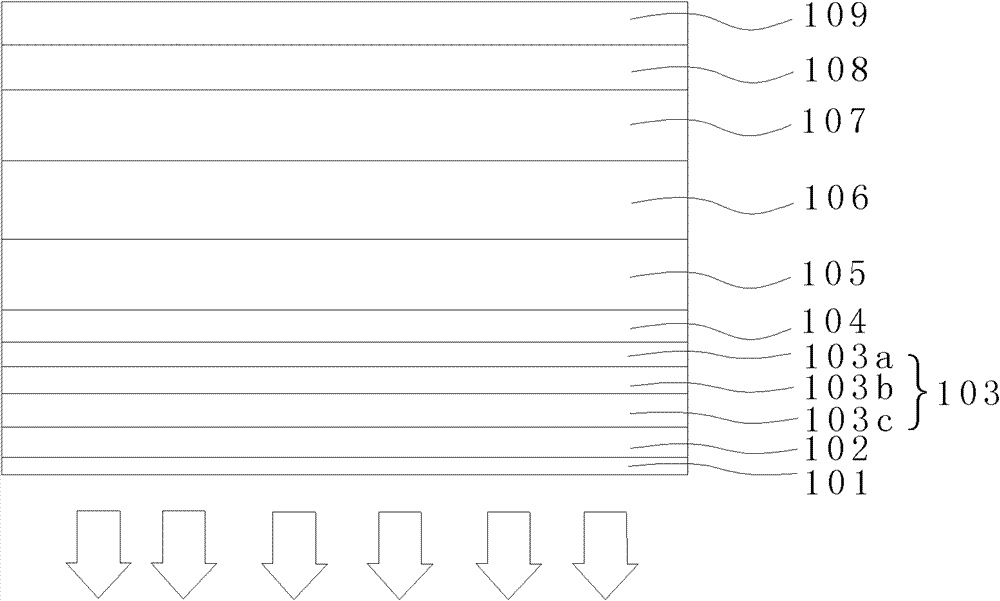

[0047] A flexible organic light-emitting diode, which is a layered structure, and the sequence of the layered structure is: PET / UV glue / ZnS / Sm / WO 3 / m-MTDATA / NPB / Ir(ppy) 3 :CBP / TPBi / LiF / Mg-Ag.

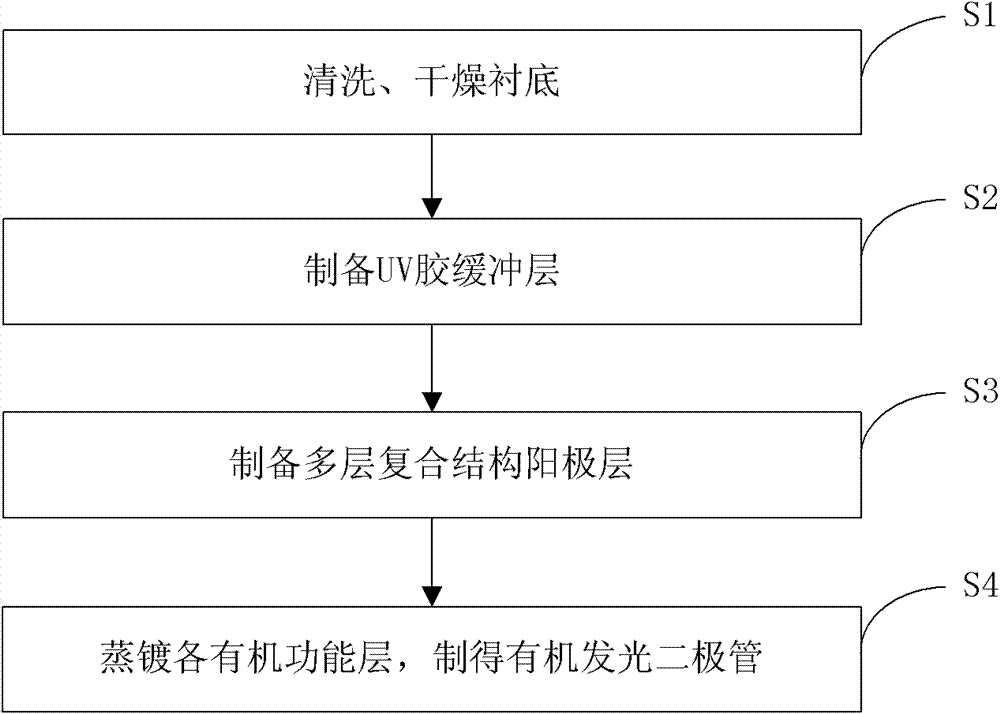

[0048] The preparation process of the flexible organic light emitting diode is as follows:

[0049] First, put the PEN film with a thickness of 0.1 mm in deionized water containing detergent for ultrasonic cleaning. After cleaning with deionized water, use isopropanol and acetone in ultrasonic treatment, and then blow dry with nitrogen;

[0050] Then, the PEN film is placed on the glue leveler, start the glue leveler, and the speed of the glue leveler is at 1000 rpm, and a layer of UV glue with a thickness of 0.5 μm is spin-coated on the surface of the PEN film as a smooth layer. After 120 seconds, use UV light to cure to form a buffer layer;

[0051] Subsequently, in a vacuum of 5×10 -4 In the coating system of Pa, a ZnS layer with a thickness of 40nm, an Sm layer with a thickness...

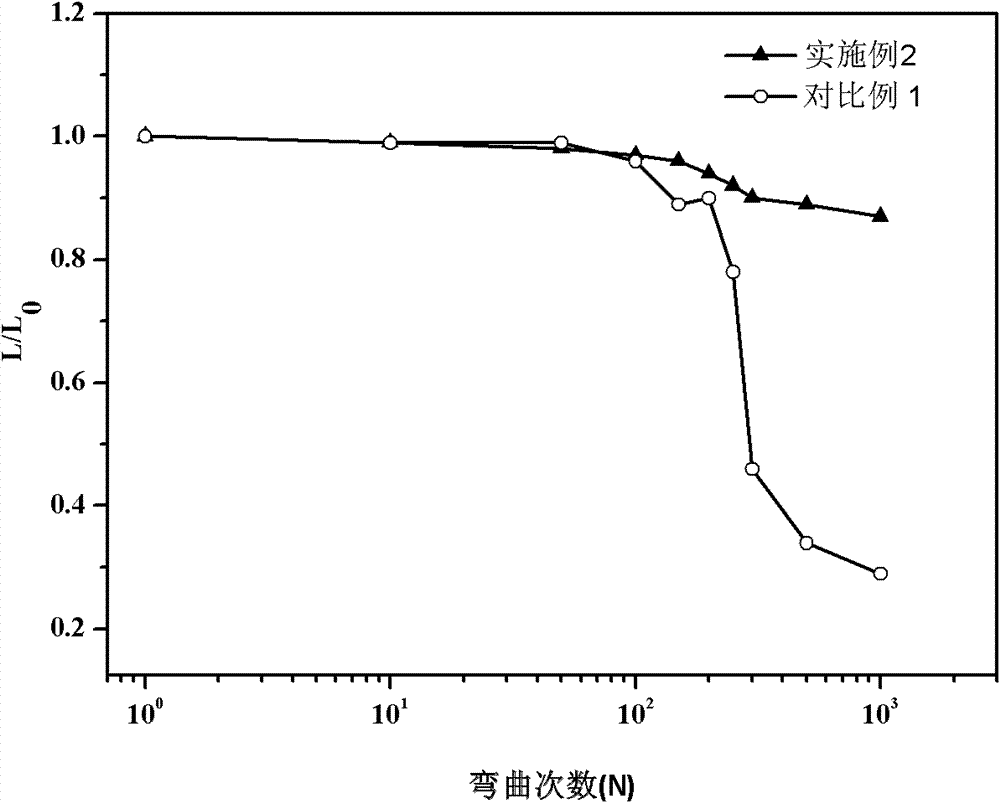

Embodiment 2

[0054] A flexible organic light-emitting diode, which is a layered structure, and the sequence of the layered structure is: PET / UV glue / ZnS / Sm / V 2 o 5 / CuPc / TPD / Ir(ppy) 3 : CBP / Bphen / CsF / Ag.

[0055] The preparation process of the flexible organic light emitting diode is as follows:

[0056] First, put the PET film with a thickness of 0.175mm in deionized water containing detergent for ultrasonic cleaning, after cleaning with deionized water, use isopropanol and acetone in ultrasonic treatment, and then blow dry with nitrogen;

[0057] Secondly, the PET film is placed on the glue leveling machine, start the glue leveling machine, and the rotating speed of this glue leveling machine is at 5000 revs / min, spin-coat a layer of thickness on the surface of the PEN film and be 5 μ m UV glue as a leveling layer, the glue leveling time is 30 Seconds later, use UV light to cure to form a buffer layer;

[0058] Subsequently, in a vacuum of 5×10 -4 In the coating system of Pa, a ZnS ...

Embodiment 3

[0061] A flexible organic light-emitting diode, which is a layered structure, and the sequence of the layered structure is: PES / UV glue / ZnSe / Sm / WO 3 / m-MTDATA / TDAPB / Ir(ppy) 3 :CBP / Alq 3 / LiF / Al.

[0062] The preparation process of the flexible organic light emitting diode is as follows:

[0063] First, put the PES film with a thickness of 0.2mm in deionized water containing detergent for ultrasonic cleaning. After cleaning with deionized water, use isopropanol and acetone in ultrasonic treatment, and then blow dry with nitrogen;

[0064] Then, the PES film is placed on the glue leveler, the glue leveler is started, and the speed of the glue leveler is 4000 rpm, and a layer of UV glue with a thickness of 1 μm is spin-coated on the surface of the PEN film as a leveling layer, and the glue leveling time is 70 Seconds later, use UV light to cure to form a buffer layer;

[0065] Subsequently, in a vacuum of 5×10 -4 In the coating system of Pa, a ZnSe layer with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com