Skin care product containing biological buffering agent

A technology for biological buffers and skin care products, applied in the field of skin care products containing biological buffers, can solve the problems of loss of efficacy of extracts, inactivation of active substances, and easy inactivation, and achieve long-lasting anti-aging effects and chemical properties. Stable, small pH drift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

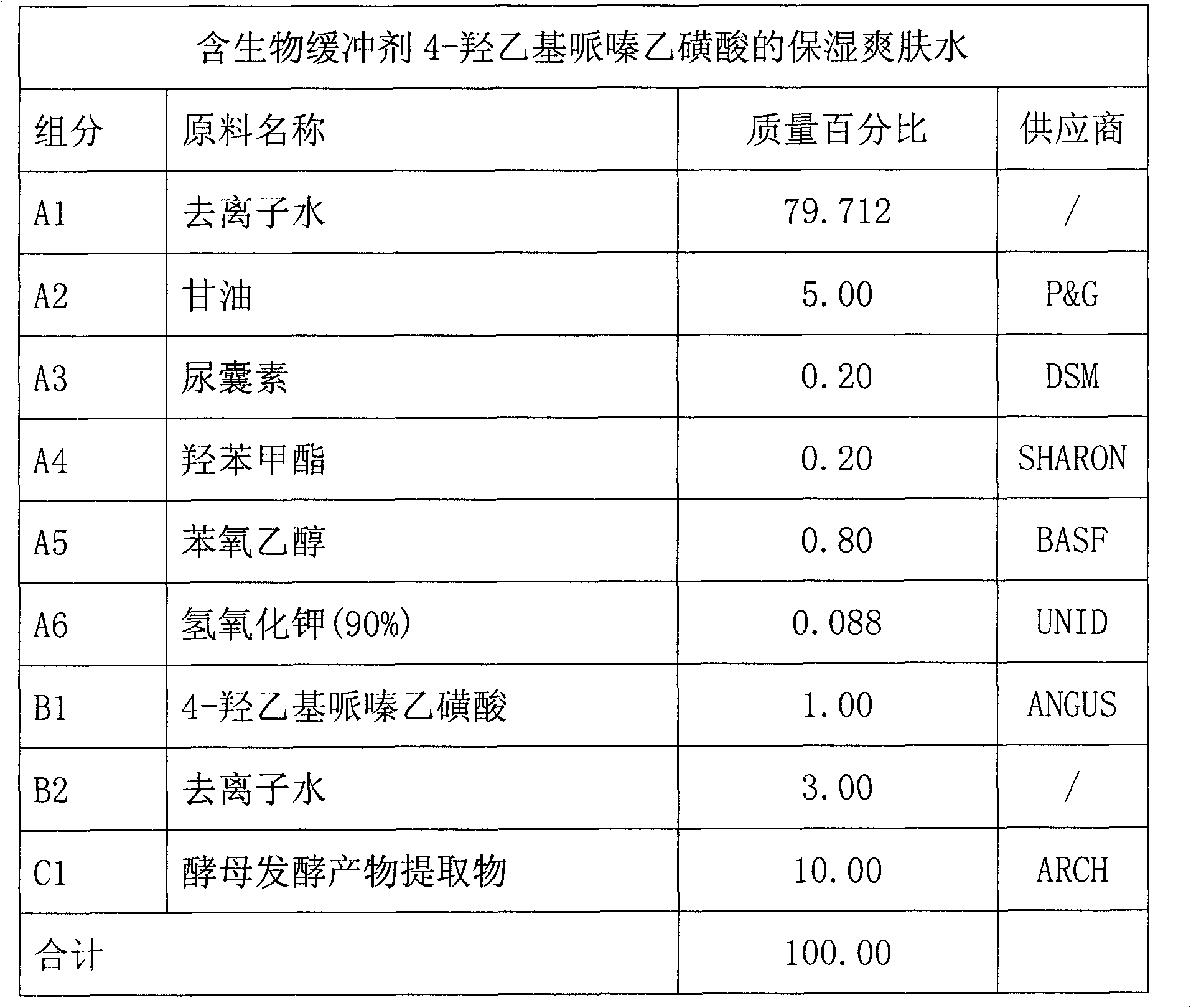

[0011] Example 1: Moisturizing toner containing biological buffer 4-hydroxyethylpiperazineethanesulfonic acid

[0012]

[0013] Preparation Process:

[0014] 1. Main pot: Stir components A1-A6 evenly, heat to 65°C, keep warm for 10 minutes, stir until completely dissolved, then cool down to 38°C;

[0015] 2. Pre-mixing pot: pre-mix B1 and B2 components, stir until completely dissolved, then add to the main pot, and stir evenly;

[0016] 3. Add component C1 into the main pot and stir well to obtain a moisturizing toner containing biological buffer 4-hydroxyethylpiperazineethanesulfonic acid.

[0017] The pH value of this example was 7.05 when the preparation was completed. After 3 years of storage in the dark at room temperature, the measured pH value was 6.81. After 3 years of storage, the total polypeptide content was 94.2% of the original content.

Embodiment 2

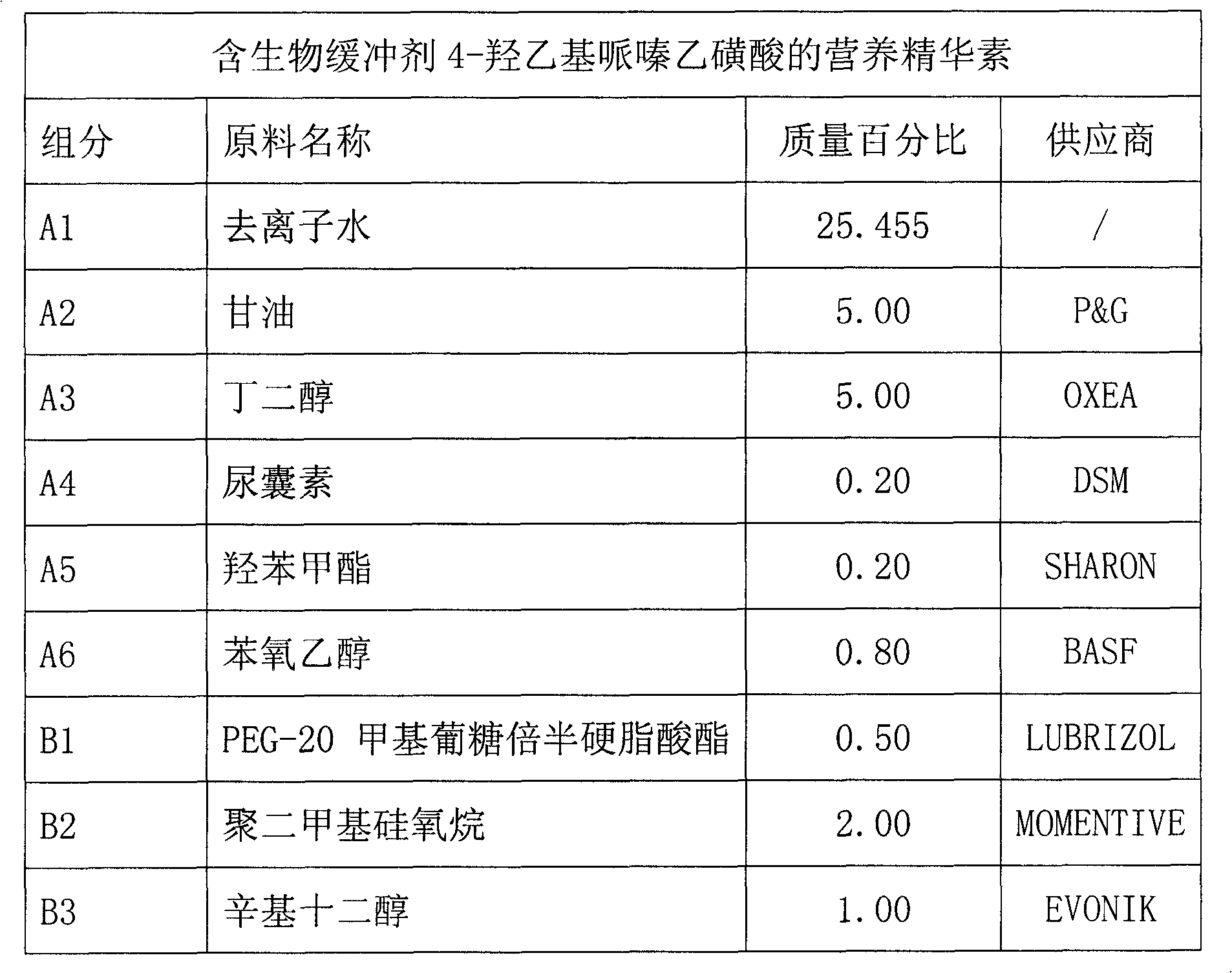

[0018] Embodiment two: the nutritional essence containing biological buffer 4-hydroxyethylpiperazineethanesulfonic acid

[0019]

[0020]

[0021] Preparation Process:

[0022] 1. Main pot: Stir components A1-A6 evenly, heat to 75°C, and stir until completely dissolved;

[0023] 2. Oil phase pot: put components B1-B3 into the oil phase pot, heat to 75°C, and stir until completely dissolved;

[0024] 3. Main pot: Pour the contents of the oil phase pot into the main pot, maintain the temperature at 75°C, 3000rpm, homogenize for 30 minutes, and then cool down to 45°C;

[0025] 4. Main pot: Put C1 component into the main pot, keep the temperature at 45°C, 3000rpm, homogenize for 10 minutes, then cool down to 38°C;

[0026] 5. Pre-mixing pot: pre-mix D1, D2, D3 components, stir to dissolve;

[0027] 6. Add the D1, D2, and D3 components that are evenly mixed into the main pot, and stir evenly;

[0028] 7. Add the E1 component into the main pot, stir evenly, and cool to 33°...

Embodiment 3

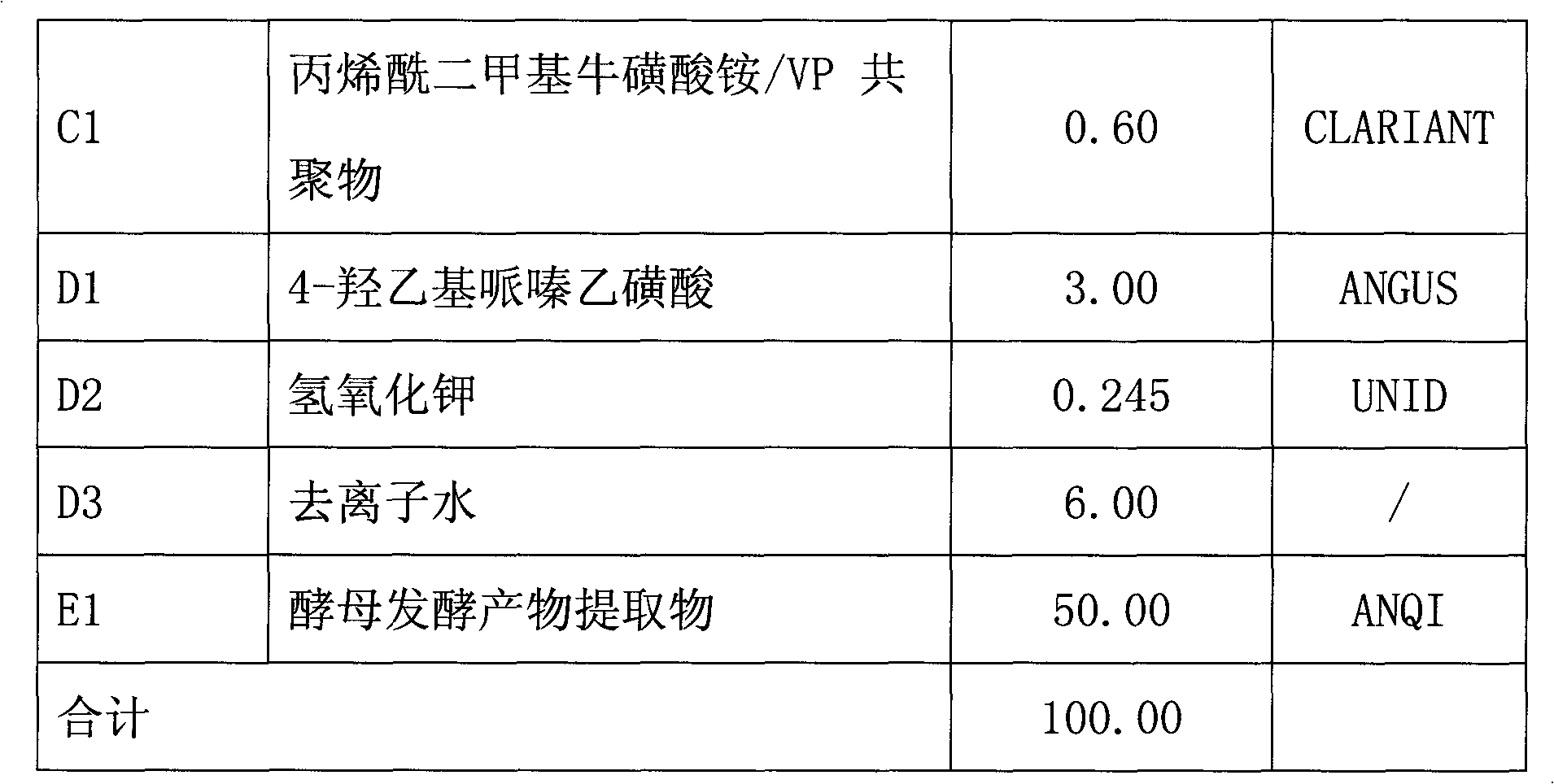

[0030] Example Three: Whitening Emulsion Containing Biological Buffer 4-Hydroxyethylpiperazineethanesulfonic Acid

[0031]

[0032]

[0033] Preparation Process:

[0034] 1. Main pot: Mix and stir components A1-A8, heat to 75°C, and stir until completely dissolved;

[0035] 2. Oil phase pot: put components B1-B9 into the oil phase pot, heat to 75°C, and stir until completely dissolved;

[0036] 3. Main pot: Pour the contents of the oil phase pot into the main pot, maintain the temperature at 75°C, 3000rpm, homogenize for 30 minutes, and then cool down to 45°C.

[0037] 4. Main pot: Put the C1 component into the main pot, maintain the temperature at 45°C, 3000rpm, homogenize for 10 minutes, and then cool down to 38°C.

[0038] 5. Pre-mixing pot: pre-mix D1, D2, D3 components, stir to dissolve;

[0039] 6. Add the D1, D2, and D3 components that are evenly mixed into the main pot, and stir evenly;

[0040] 7. Add components E1 and E2 into the main pot, stir evenly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com