Release agent for lead-acid battery cast-welding and preparation method thereof

A technology of lead-acid battery and mold release agent, which is applied to casting molding equipment, molds, mold components, etc. It can solve the problems of poor thermal insulation performance, reduced mold life, and large mold damage, and achieves improved surface finish and enhanced welding. effect, reduce the effect of work links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment: the concrete steps of producing lead-acid accumulator cast-welding mold release agent are as follows:

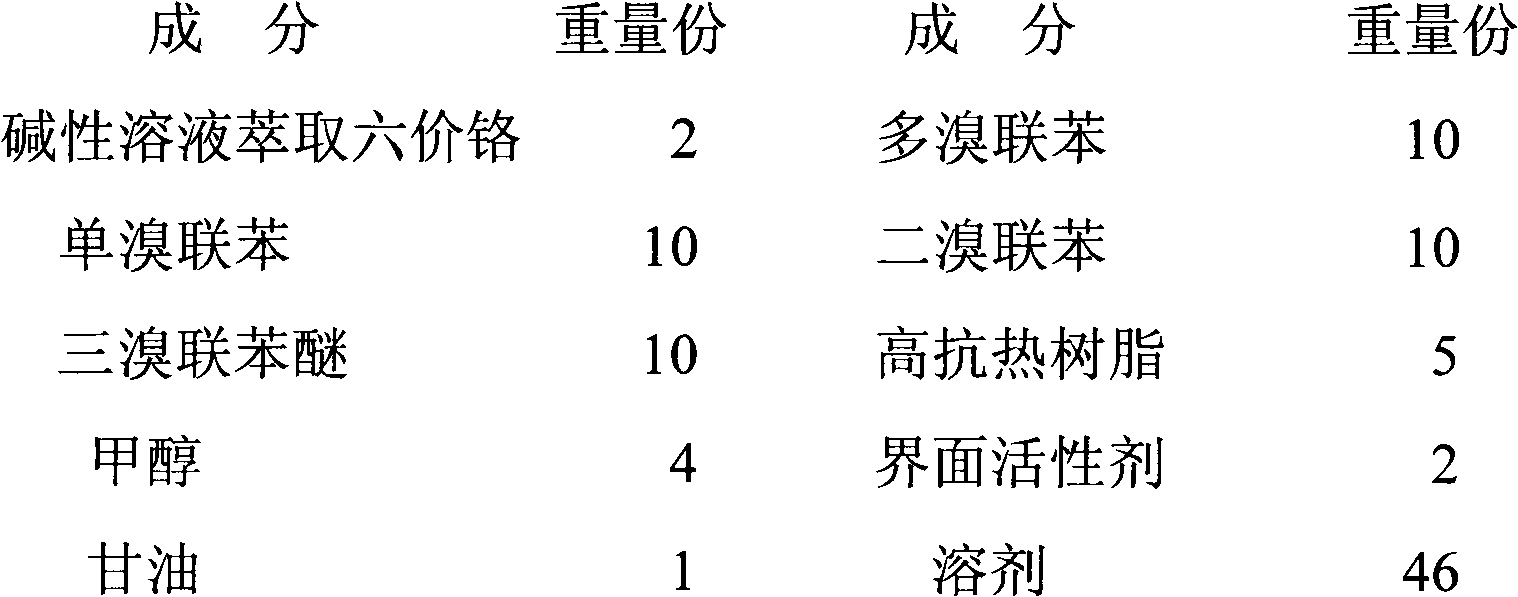

[0016] Take alkaline solution to extract and measure hexavalent chromium 2, polybrominated biphenyl 10, monobrominated biphenyl 10, dibrominated biphenyl 10, tribrominated diphenyl ether 10, high heat-resistant resin 5, methanol 4, surfactant 2, glycerin 1, Solvent46.

[0017] (1), glycerin, surfactant are heated to 80-100 ℃ according to component content;

[0018] (2), add methanol according to component content and stir for 1 hour;

[0019] (3), add alkaline solution to extract and measure hexavalent chromium, polybrominated biphenyls, monobrominated biphenyls, dibrominated biphenyls, tribrominated diphenyl ethers, high heat-resistant resin and solvent according to the component content and stir for 1 hour;

[0020] (4) Add a little pigment and stir to adjust the color.

[0021] The release agent properties after preparation is:

[0022] Viscosity: m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com