Method for carrying out micro-arc oxidation on blue-colored film layer by aluminum alloy

A technology of micro-arc oxidation and aluminum alloy, which is applied in anodic oxidation and other directions, can solve the problems of weak bonding between the film layer and the substrate, and the corrosion resistance needs to be improved, and achieve the effects of low porosity, good wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

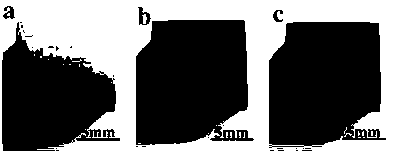

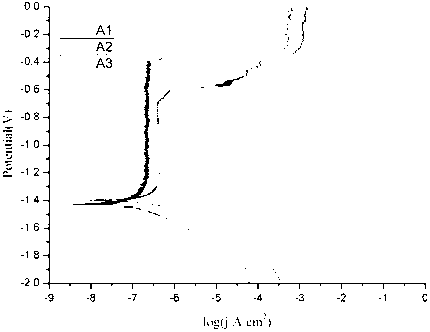

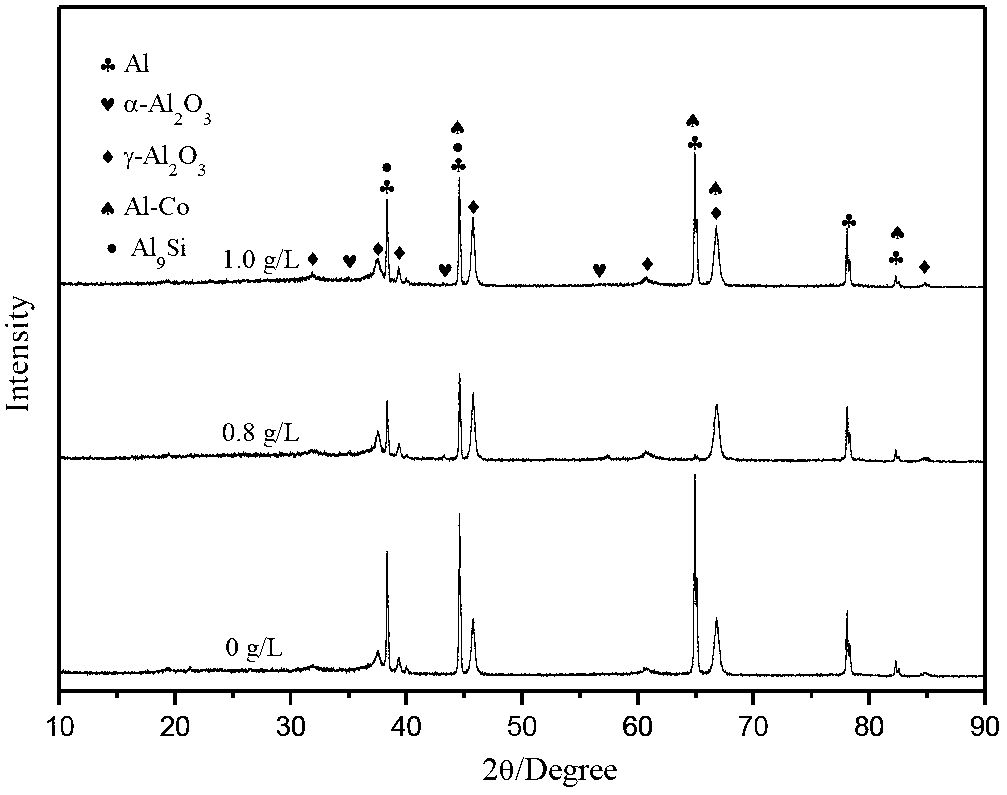

Embodiment 1

[0028] The pre-treated 6063 aluminum alloy pattern was immersed in the prepared electrolyte, the electrical parameters of the test were set, and the pattern was subjected to micro-arc oxidation treatment for 15 minutes. The electrolyte parameters are: sodium silicate concentration 8g / L; potassium hydroxide concentration 1.5g / L; sodium fluoride concentration 0.5g / L; cobalt sulfate concentration is 0.6g / L. The electrical parameters are: the positive and negative voltages are 460V and 100V, respectively; the frequency is 300HZ; the positive and negative duty ratios are 60% and 30%, respectively. The resulting film is light blue, and the surface is smooth and compact, namely A1 .

Embodiment 2

[0030] Changing the concentration of cobalt sulfate in Example 1 to 0.8 g / L, and other parameters unchanged, the resulting film is blue, with a smooth and dense surface, that is, A2.

Embodiment 3

[0032] The concentration of cobalt sulfate in Example 1 is changed to 1.0 g / L, and other parameters remain unchanged, and the obtained film is dark blue with rough surface, namely A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com