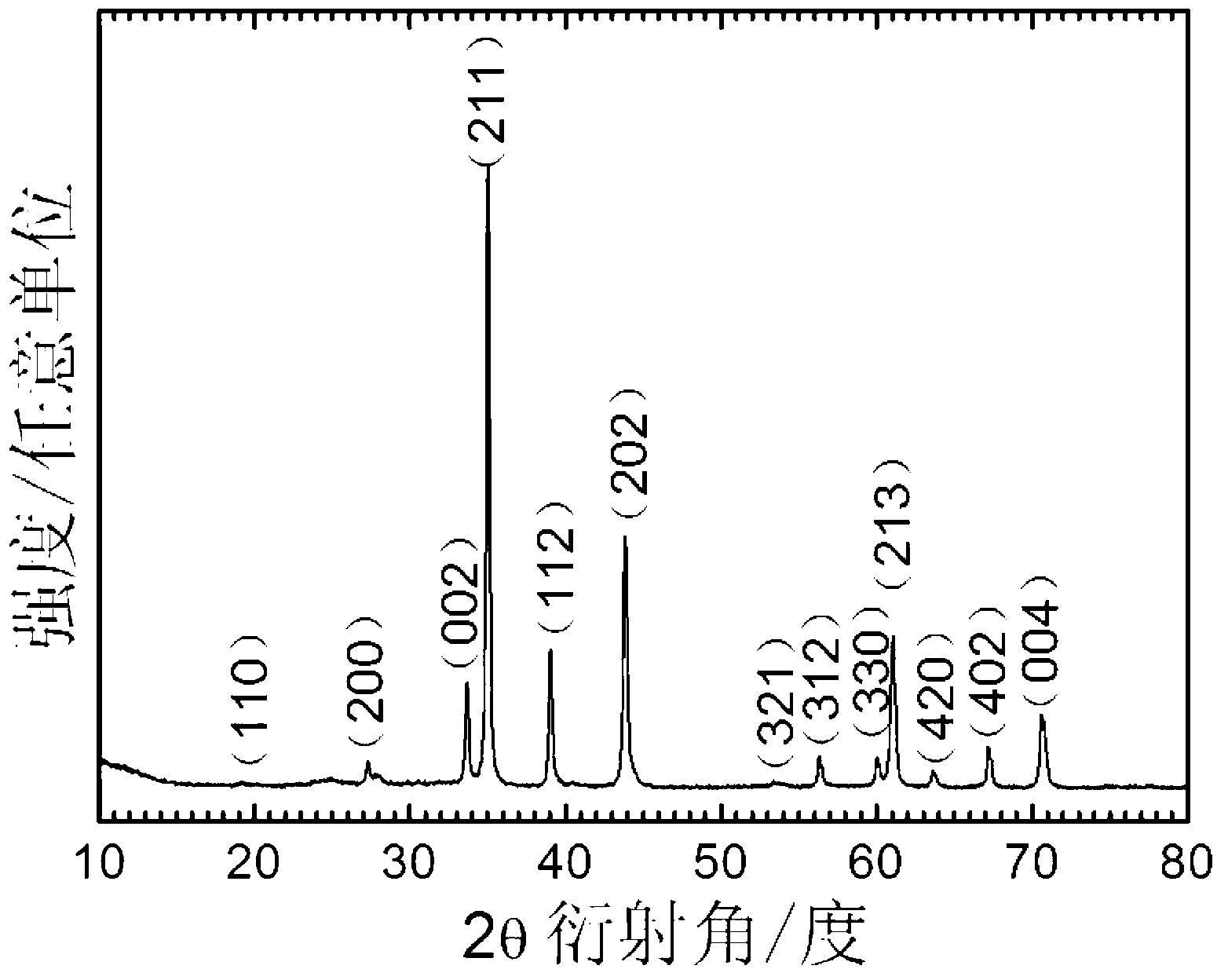

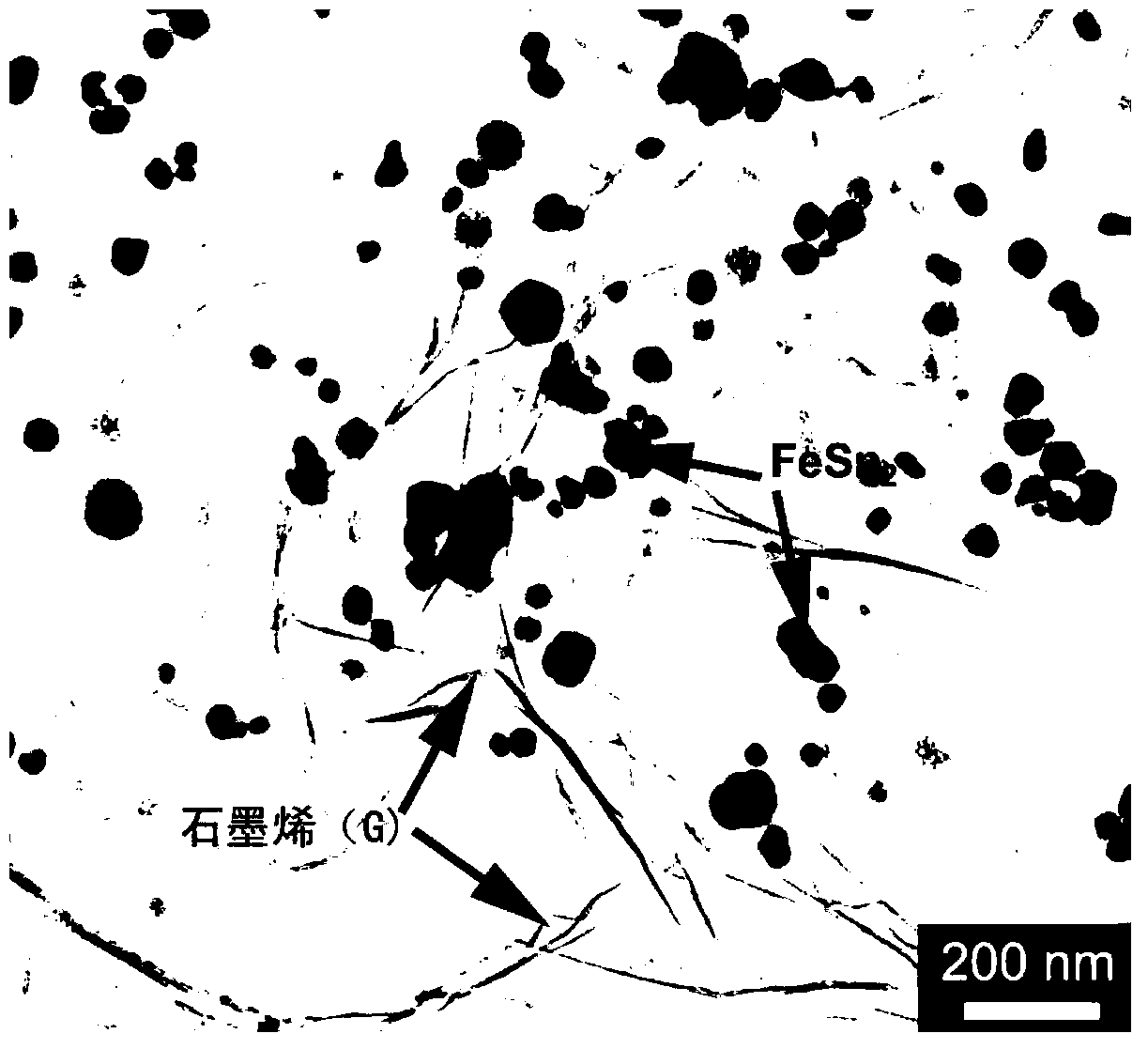

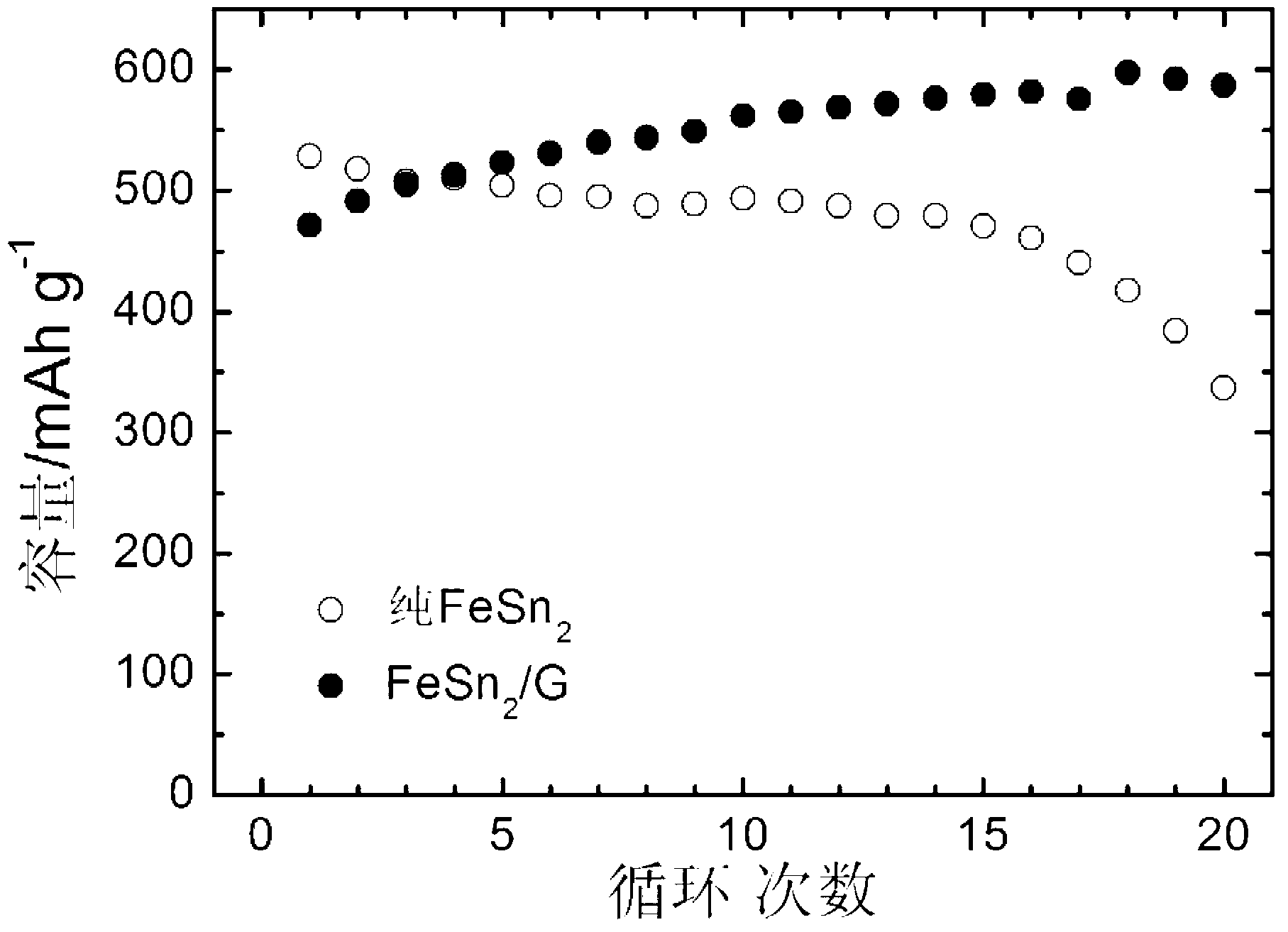

Transition metal tin compound/graphene composite material and preparation method and application thereof

A technology of transition metals and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor electrochemical stability of tin-based alloy materials, high raw material requirements, and increased production costs, so as to improve electrochemical stability, The effect of high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Dissolve 106 mg of GO in an appropriate amount of ethylene glycol and sonicate until completely dispersed to obtain a homogeneous solution of GO.

[0035] 2) The analytically pure SnCl 2 2H 2 O and FeCl 3 ·6H 2 O, according to the ratio of Fe:Sn atomic ratio 1:2, dissolved in ethylene glycol to obtain FeSn 2 Concentration is 80 milliliters of the solution of 0.015mol / L, this solution is added in the homogeneous solution of GO of step 1), after stirring evenly, make mixed solution.

[0036] 3) The mixed solution of step 2) is placed in a high-pressure reactor with a capacity of 100 milliliters (filling degree 80%, percent by volume), and 2.3 grams of reducing agent NaBH are added in the solution 4 , then seal immediately.

[0037] 4) Heating the reactor to 230°C and reacting for 32 hours.

[0038] 5) After the reaction, cool down to room temperature naturally, collect the powdery reaction product at the bottom of the kettle, wash it with deionized water and absolu...

Embodiment 2

[0042] 1) Dissolve 142 mg of GO in an appropriate amount of deionized water, and sonicate until completely dispersed to obtain a homogeneous solution of GO.

[0043] 2) The analytically pure SnCl 4 ·5H 2 O and CoCl 2 ·6H 2 O, NiSO 4 ·7H 2 O, according to the ratio of Co: Ni: Sn atomic ratio 0.9: 0.1: 2, dissolved in deionized water to obtain Co 0.9 Ni 0.1 sn 2 The concentration is 80 milliliters of the solution of 0.03mol / L, this solution is added in step 1) in the homogeneous solution of GO, after stirring evenly, make mixed solution.

[0044] 3) Place the mixed solution of step 2) in a high-pressure reactor with a capacity of 100 ml (filling degree 80%, volume percentage), and add 4.5 grams of reducing agent KBH4 to the solution, and then seal it immediately.

[0045] 4) Heating the reactor to 230°C and reacting for 36 hours.

[0046] 5) After the reaction, cool down to room temperature naturally, collect the powdery reaction product at the bottom of the kettle, was...

Embodiment 3

[0050] 1) Dissolve 300 mg of graphene oxide (GO) in an appropriate amount of ethylene glycol and sonicate until completely dispersed to obtain a homogeneous solution of GO.

[0051] 2) The analytically pure SnCl 2 2H 2 O and NiCl 2 ·6H 2 O, according to the ratio of Ni:Sn atomic ratio 3:2, dissolved in ethylene glycol to obtain Ni 3 sn 2 Concentration is 80 milliliters of the solution of 0.09mol / L, this solution is added in the homogeneous solution of GO of step 1), after stirring evenly, make mixed solution.

[0052] 3) The mixed solution of step 2) is placed in a high-pressure reactor with a capacity of 100 milliliters (filling degree 80%, percent by volume), and 5.4 grams of reducing agent NaBH are added in the solution 4 , then seal immediately.

[0053] 4) Heating the reactor to 240°C and reacting for 28 hours.

[0054] 5) After the reaction, cool down to room temperature naturally, collect the powdery reaction product at the bottom of the kettle, wash it with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com