A kind of manufacturing method of lead-carbon battery for micro-hybrid electric vehicle

A technology for power vehicles and manufacturing methods, applied in the direction of lead-acid batteries, lead-acid battery construction, battery electrodes, etc., can solve the problems of battery life end, plate swelling and deformation, active material softening, etc., and achieve easy operation and high through-hole rate High, less impurity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

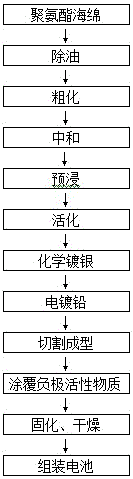

[0022] Example 1: Such as figure 1 As shown, the manufacturing steps of a lead-carbon battery for micro-hybrid vehicles are:

[0023] (1) Degreasing: Soak a 200×200×2.5 mm polyurethane sponge in 3g / L sodium hydroxide, 10g / L sodium carbonate, 5g / L trisodium phosphate, and 0.5g / L OP-10 emulsifier. In the mixed solution, the temperature is room temperature and the soaking time is 2 minutes;

[0024] (2) Coarse: soak the degreasing polyurethane sponge in a mixed solution of 500ml / L sulfuric acid and 10g / L potassium dichromate for 5 minutes;

[0025] (3) Neutralization: soak the roughened polyurethane sponge in 80 g / L sodium hydroxide solution for 1 minute;

[0026] (4) Pre-soak: soak the neutralized polyurethane sponge in a prepreg for 30 minutes, the prepreg is 10g / L of stannous chloride and 40ml / L of hydrochloric acid;

[0027] (5) Activation: soak the pre-soaked polyurethane sponge in the activation solution for 5 minutes, the activation solution is a mixture of silver nitrate 2g / L and ...

Embodiment 2

[0038] A lead-carbon battery for micro-hybrid vehicles, the manufacturing steps are:

[0039] (1) Degreasing: Soak a 200×200×2 mm polyurethane sponge in a mixture containing 5g / L sodium hydroxide, 30g / L sodium carbonate, 10g / L trisodium phosphate, and 3g / L OP-10 emulsifier. In the mixed solution, the temperature is room temperature, and the soaking time is 10 minutes;

[0040] (2) Coarse: soak the degreasing polyurethane sponge in a mixed solution of 200ml / L sulfuric acid and 30g / L chromic anhydride for 10 minutes;

[0041] (3) Neutralization: soak the roughened polyurethane sponge in 100 g / L sodium hydroxide solution for 5 minutes;

[0042] (4) Pre-soaking: soak the neutralized polyurethane sponge in a prepreg for 15 minutes. The prepreg is 10g / L stannous chloride and 40ml / L hydrochloric acid;

[0043] (5) Activation: soak the pre-soaked polyurethane sponge in the activation solution for 30 minutes, the activation solution is a mixture of silver nitrate 8g / L and ammonia (25%) 24ml / L; ...

Embodiment 3

[0053] The manufacturing steps of a lead-carbon battery for micro-hybrid vehicles are:

[0054] (1) Degreasing: soak a 200×200×2 mm polyurethane sponge in a mixture containing 4g / L sodium hydroxide, 20g / L sodium carbonate, 7g / L trisodium phosphate, and 5g / L OP-10 emulsifier In the solution, the temperature is room temperature, and the soaking time is 8 minutes;

[0055] (2) Coarse: Soak the degreasing polyurethane sponge in a mixed solution of 400ml / L sulfuric acid and 90g / L chromic anhydride for 10 minutes;

[0056] (3) Neutralization: soak the roughened polyurethane sponge in 70 g / L sodium hydroxide solution for 10 minutes;

[0057] (4) Pre-soaking: soak the neutralized polyurethane sponge in a prepreg solution for 22 minutes. The prepreg solution is stannous chloride 60g / L and hydrochloric acid 200ml / L;

[0058] (5) Activation: soak the pre-soaked polyurethane sponge in the activation solution for 25 minutes, the activation solution is a mixture of silver nitrate 10g / L and ammonia (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com