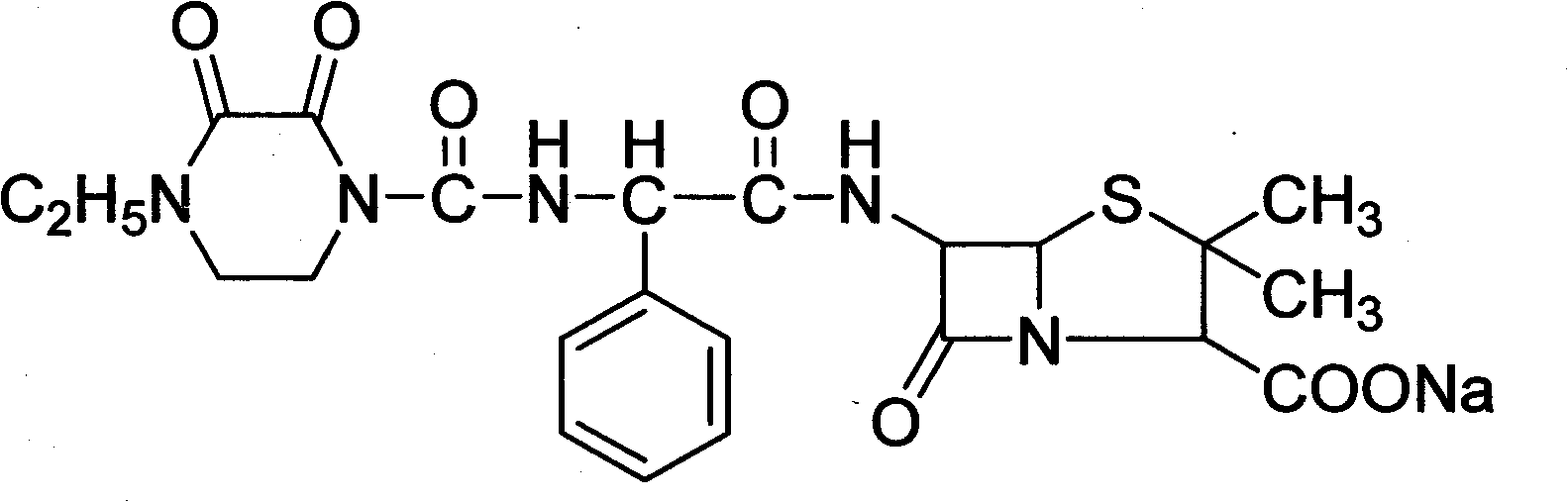

Refining method for piperacillin sodium

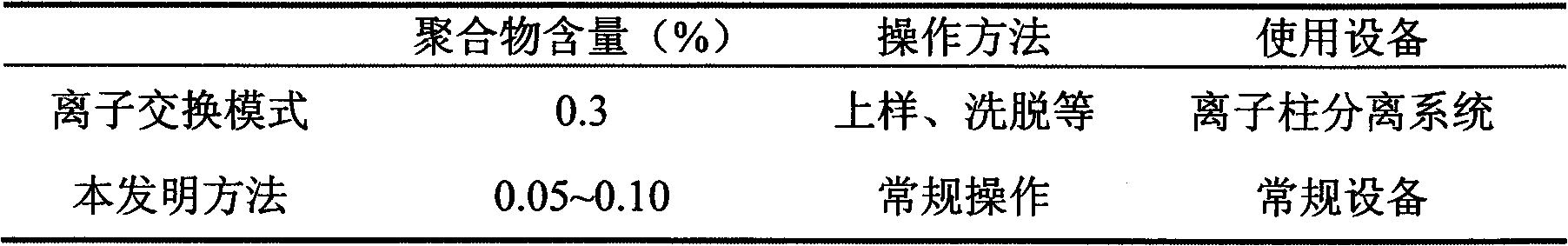

A piperacillin sodium and refining method technology, applied in the field of polymer removal, can solve the problems of high equipment cost, large solvent volume, cumbersome operation, etc., and achieve the effect of low production cost, simple operation and good refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of piperacillin sodium crude product is as follows:

[0021] 1. In a dry reactor, add 7kg (49mol) of dioxypiperazine and 45L of dichloromethane, cool to -10°C, add 6.4kg (59mol) of trimethylchlorosilane, and add 6.0kg of triethylamine dropwise at the same temperature kg (59mol), reacted for 2 hours after dropping, and the solution was pale yellow. Then cool to -20°C, add 5.3 kg (18 mol) of triphosgene in batches, and react for 3 hours, the reaction solution changes from light yellow to light red. Filter and use the filtrate for later use.

[0022] 2. In a dry reaction kettle, add 150 L of dichloromethane, 16 kg (40 mol) of ampicillin trihydrate, and drop triethylamine to dissolve and clarify the solid. Add the above-mentioned steps to obtain the acid chloride solution in the product, and keep warm for reaction after adding. Add 3 mol / L HCl dropwise to acidify, adjust pH=1.5-2.0, let stand to separate layers, and discard the water layer. 250 L ...

example 1

[0024] The refining of example 1 piperacillin sodium crude product

[0025] Add 15.00kg of crude piperacillin sodium into 15L of water and 30L of DMSO, stir at 50°C to fully dissolve; add 1.5kg of activated carbon, stir well and filter while hot; add 75L of acetone dropwise to the filtrate; Room temperature; transfer to 5-10°C for 3 hours of heat preservation, stirring and crystallization; filter the filter cake and rinse with 1L of ice acetone; dry to obtain 11.85kg of refined piperacillin sodium, the polymer content of which is 0.09% as detected by HPLC.

example 2

[0026] The refining of example 2 piperacillin sodium crude product

[0027] Add 15.00kg of crude piperacillin sodium into 15L of water and 30L of DMSO, stir and fully dissolve at 50°C; add 1.5kg of activated carbon, stir well and filter while hot; add 150L of acetone dropwise to the filtrate; naturally cool down to room temperature while stirring ; Transfer to -10 ~ -5 ℃ heat preservation, stirring and crystallization for 5 hours; filter the filter cake and rinse with 1L of ice acetone; dry to obtain 12.30kg of piperacillin sodium refined product, the polymer content of HPLC is 0.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com