Method for extracting solanesol by activating waste and defective tobacco by enzyme catalysis

A catalytic activation and tobacco extraction technology, applied in the separation/purification of hydroxyl compounds, can solve the problems of reducing the economic value of solanesol products, shortening the service life of production equipment, affecting the market price of solanesol, and achieving biological activity The effects of complete preservation, environmental protection, and reduction of production safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

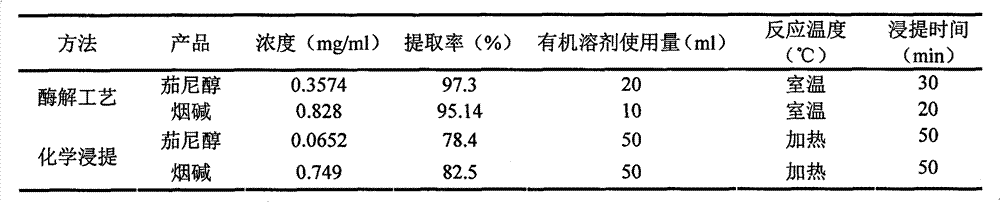

[0024] The specific steps of a method for enzymatically activating waste tobacco to extract solanesol are as follows:

[0025] (1) Raw material pretreatment

[0026] Wash 40g of discarded tobacco leaves, dry them, place them in an oven, bake them in an oven at 100°C for 60 minutes, take them out, crush them with a pulverizer, and pass through a 60-mesh molecular sieve to obtain tobacco leaves with a particle size of less than 60 mesh. Pack in separate bags and set aside.

[0027] (2) Enzymolysis reaction

[0028]After the first (1) step is completed, first according to the quality (g) of the tobacco solid waste after the (1) step treatment: the quality (g) of enzyme: the ratio of the volume (ml) of water is 1: 0.4: 5 Ratio, in the tobacco solid waste after the pretreatment in step (1), add enzyme and water, after stirring evenly, then adjust the pH value of the system with sulfuric acid solution to be 6, then place the mixed solution after adjusting the pH value in In a sha...

Embodiment 2

[0036] A method for enzymatically activating waste tobacco to extract solanesol, the same as in Example 1, wherein:

[0037] In step (1), the temperature of the oven is 110° C., the drying time is 30 minutes, and the waste tobacco leaves are passed through a 160-mesh sieve.

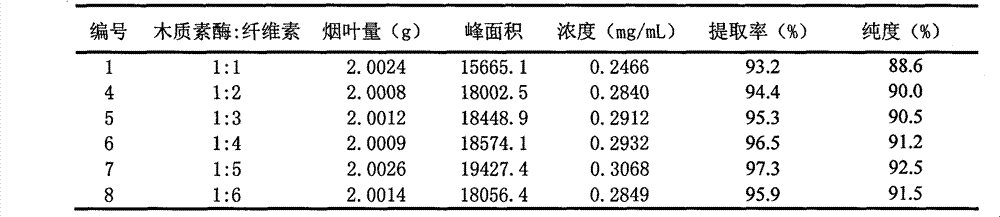

[0038] In the (2) step, the quality (g) of tobacco solid waste: the quality (g) of enzyme: the volume (ml) ratio of water is 1: 0.6: 15, and the pH value of regulating system with sodium hydroxide solution is 9 , under the condition that the temperature of the water bath on the shaker is 60° C., the enzymatic activation is carried out for 2 hours. The enzyme is a composite enzyme with a mass ratio of ligninase:cellulase of 1:6.

[0039] In the (3) step, the quality (g) of the tobacco solid waste after the pretreatment of the (1) step: composite extractant solution volume (ml) ratio is 1: 12, and composite extractant ethanol: the volume ratio of methyl alcohol is 1:9. The ultrasonic power is 40W, the ul...

Embodiment 3

[0043] A method for enzymatically activating waste tobacco to extract solanesol, the same as in Example 1, wherein:

[0044] In step (1), the oven temperature is 85° C., the drying time is 90 minutes, and the waste tobacco leaves are passed through a 20-mesh sieve.

[0045] In the (2) step, the quality (g) of tobacco solid waste: the quality (g) of enzyme: the volume (ml) ratio of water is 1: 0.1: 1, and the pH value of regulating system with sulfuric acid solution is 4, in The temperature of the water bath on the shaker was 25° C., and the enzymatic activation was carried out for 14 hours. The enzyme is a composite enzyme with a mass ratio of ligninase:cellulase of 1:1.

[0046] In the 3rd step, the quality (g) of the tobacco solid waste after the pretreatment of the 1st step: composite extractant solution volume (ml) ratio is 1: 8, and composite extractant ethanol: the volume ratio of methyl alcohol is 1:4. The ultrasonic power is 200W, the ultrasonic temperature is 30°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com