High-activity TiO2 nanometer pipe/ intermediate phase carbon microsphere composite material and preparation method and application thereof

A technology of mesophase carbon microspheres and nanotubes, which is applied in electrical components, electrolytic capacitors, capacitors, etc., and can solve problems such as unsuitability for industrial mass production, application restrictions, and high price of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

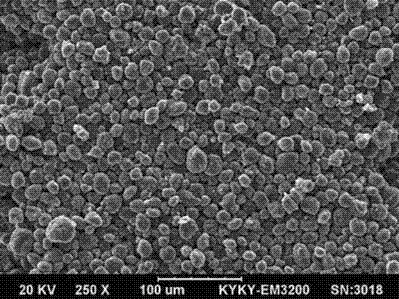

[0055] Example 1 High activity TiO 2 Preparation of Nanotube / Mesophase Carbon Microsphere Composite

[0056] (1) Weigh 500g of mesophase carbon microspheres and 1000g of KOH, mix them evenly, add water to make a paste, stir until the mixture is uniform, and put it into a carbonization furnace after vacuum drying at 80°C, N 2 Under the protection of gas, heat up to 1050°C, keep warm for 3 hours for carbonization activation, and obtain alkali-activated mesophase carbon microspheres;

[0057] (2) Weigh 200gTiO 2 powder, put it into 1mol / L NaOH solution, stir until dissolved, and the prepared TiO 2 NaOH solution;

[0058] (3) Under stirring conditions, the alkali-activated mesophase carbon microspheres prepared in step (1) and the TiO 2 Place the NaOH solution in a hydrothermal reaction kettle and mix evenly, add 600ml of distilled water, seal it, react at 110°C for 8 hours, cool, filter, wash the insoluble matter repeatedly with distilled water until th...

Embodiment 2

[0061] Example 2 High activity TiO 2 Preparation of Nanotube / Mesophase Carbon Microsphere Composite

[0062] (1) Weigh 500g of mesophase carbon microspheres and 500g of KOH, mix them evenly, add water to make a paste, stir until the mixture is uniform, and put it into a carbonization furnace after vacuum drying at 80°C, N 2 Under the protection of gas, heat up to 1000°C, keep warm for 3 hours for carbonization activation, and obtain alkali-activated mesophase carbon microspheres;

[0063] (2) Weigh 250gTiO 2 powder, put it in 1mol / L NaOH solution, stir until dissolved, and the prepared TiO 2 NaOH suspension;

[0064] (3) Under stirring conditions, the alkali-activated mesophase carbon microspheres prepared in step (1) and the TiO 2 Place the NaOH solution in a hydrothermal reaction kettle and mix evenly, add 600ml of distilled water, seal it, react at 105°C for 8h, cool, filter, wash the insoluble matter repeatedly with distilled water until the pH ...

Embodiment 3

[0066] Example 3 High activity TiO 2 Preparation of Nanotube / Mesophase Carbon Microsphere Composite

[0067] (1) Weigh 500g of mesophase carbon microspheres and 1000g of NaOH, mix them uniformly, add water to make a paste, stir until the mixture is uniform, and dry it in vacuum at 80°C, then place it in a carbonization furnace, N 2 Under the protection of gas, the temperature was raised to 1050°C and kept for 3 hours for carbonization and activation to obtain alkali-activated mesophase carbon microspheres.

[0068] (2) Weigh 150gTiO 2 powder, put it in 1mol / L NaOH solution, stir until dissolved, and the prepared TiO 2 NaOH suspension;

[0069] (3) Under stirring conditions, the alkali-activated mesophase carbon microspheres prepared in step (1) and the TiO 2 Place the NaOH solution in a hydrothermal reaction kettle and mix evenly, add 600ml of distilled water, seal it, react at 110°C for 6h, cool, filter, wash the insoluble matter repeatedly with di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com