Process for production of steel sheet for container material which has reduced load on environments, steel sheet for container material which has reduced load on environments, and laminate steel sheet for container material and coated precoat steel

A technology for container materials and manufacturing methods, applied in electrolytic inorganic material coating, metal material coating technology, transportation and packaging, etc., to achieve the effects of excellent iron dissolution resistance, easy manufacturing, and stable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] Example 1 is an example in which the steel plate is a in Table 1, the cathodic electrolytic treatment solution has a sodium sulfate concentration of 2.4% by mass, a zirconium concentration of 400 mg / L, an electrical conductivity of 1.2 S / m, and a pH of 1.9.

Embodiment 2

[0183] Example 2 is an example in which the steel plate is a in Table 1, the cathodic electrolytic treatment solution has a sodium sulfate concentration of 1.3% by mass, a zirconium concentration of 10 mg / L, an electrical conductivity of 2.0 S / m, and a pH of 1.9.

Embodiment 3

[0184] Example 3 is an example in which the steel plate is a in Table 1, the cathodic electrolytic treatment solution has a sodium sulfate concentration of 1.0% by mass, a zirconium concentration of 2000 mg / L, an electrical conductivity of 2.0 S / m, and a pH of 1.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

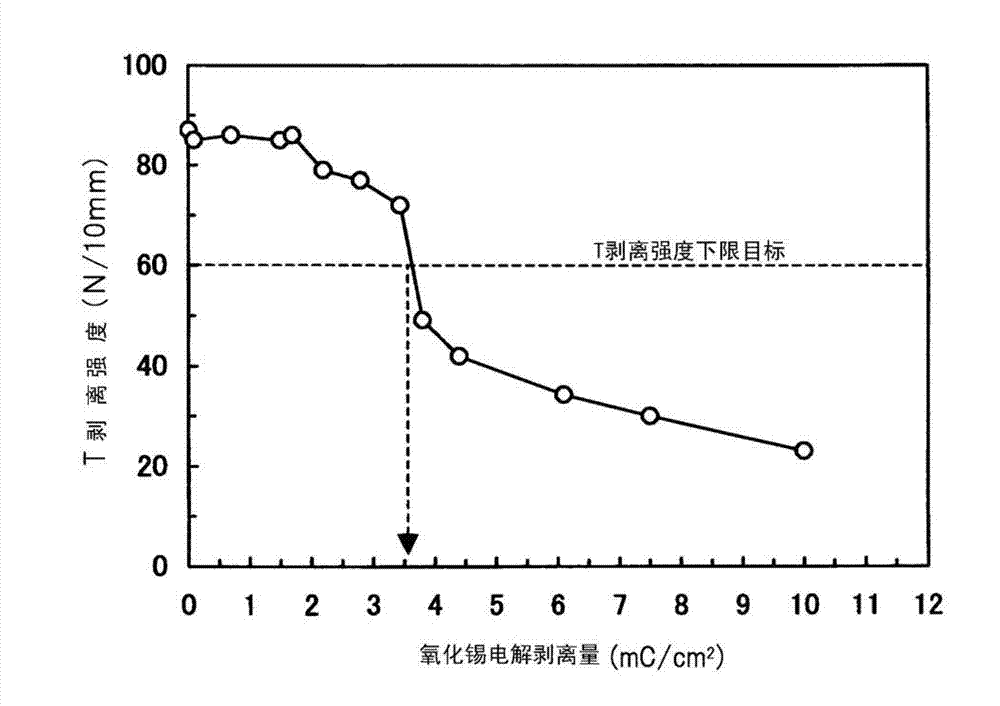

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com